Since we launched our borescope initiative in January 2024, more than 150,000 borescope images have been uploaded to Savvy’s repository, and about 100,000 of them have been reviewed by our analytical team. We’ve been particularly interested in exhaust valve images, since burned exhaust valves are the most common reason for cylinder removal.

The pattern of combustion deposits on the head of the exhaust valve—the part that is visible when the valve is closed—provides the best indication of the valve’s health. A normal valve has a symmetrical deposit pattern that has variously been compared to a bullseye or a burned pizza. If the deposit pattern is asymmetrical and lopsided, we say that the valve is “heat distressed” or “burned.” The more lopsided the pattern, the closer the valve is to failure.

Our analysts classify exhaust valve head images as “normal,” “early-stage distress,” or“late-stage distress.” Early-stage valves can almost always be repaired by lapping in place, whereas late-stage valves may require the cylinder to be removed for repair or replacement. Some images are classified as “uneven” meaning that they don’t look normal but don’t have a well-defined hot spot. Some are classified as “undetermined,”usually because the image was of poor quality and could not be assessed.

9,000 VALVES

By now, our analysts have reviewed and classified almost 9,000 of these exhaust valve images. I asked my colleague Chris Wrather Ph.D.—who heads up Savvy’s analytical division—to see what we could learn from them.Specifically, I asked Chris to determine whether Continentals suffer burned valves more often than Lycomings. I also asked him to determine whether turbocharged engines burn valves more often than normally aspirated engines.

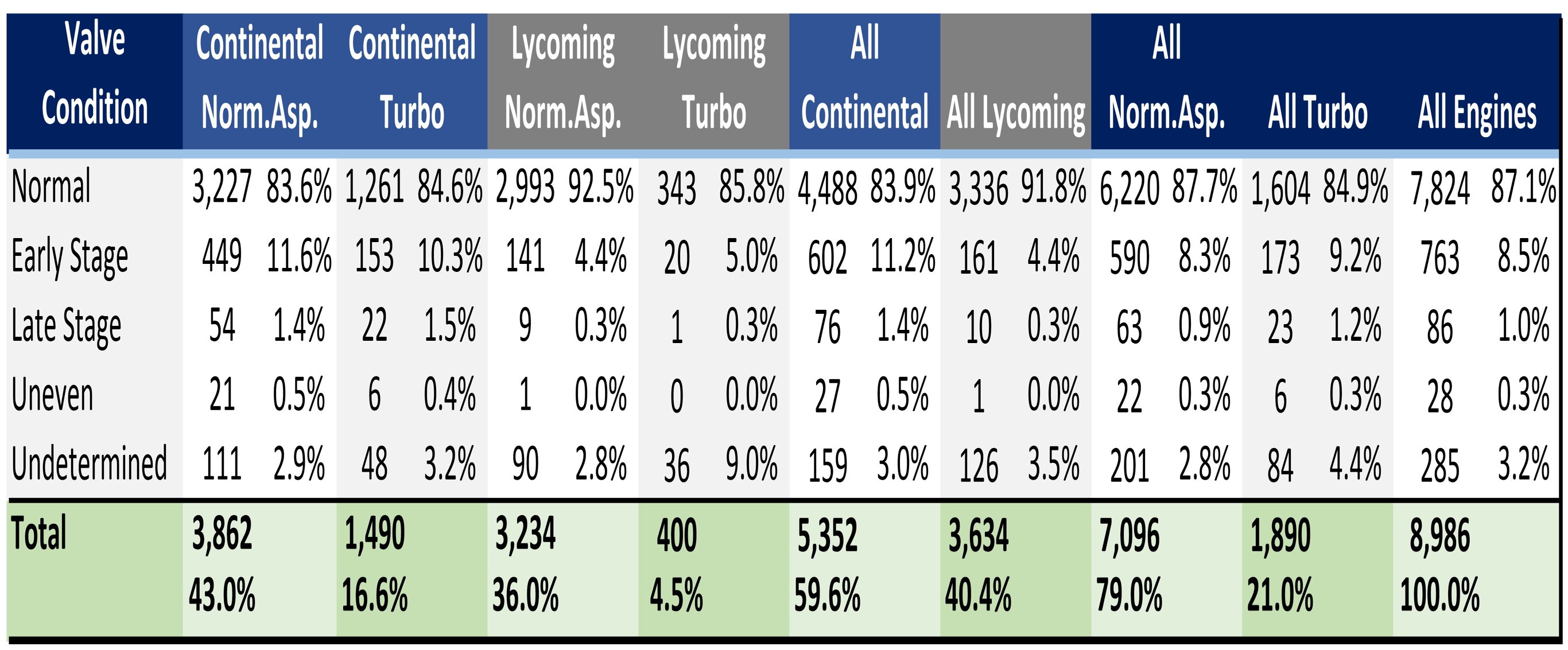

Fig. 1 – Analytical spreadsheet of 8,986 exhaust valves.

Figure 1 is the analytical spreadsheet showing the classification of 8,986 exhaust valves, including breakdowns by engine manufacturer (Continental and Lycoming) and by turbocharged vs. normally aspirated. There are an awful lot of numbers there to chew on, so I prepared a series of pie chars to illustrate the highlights.

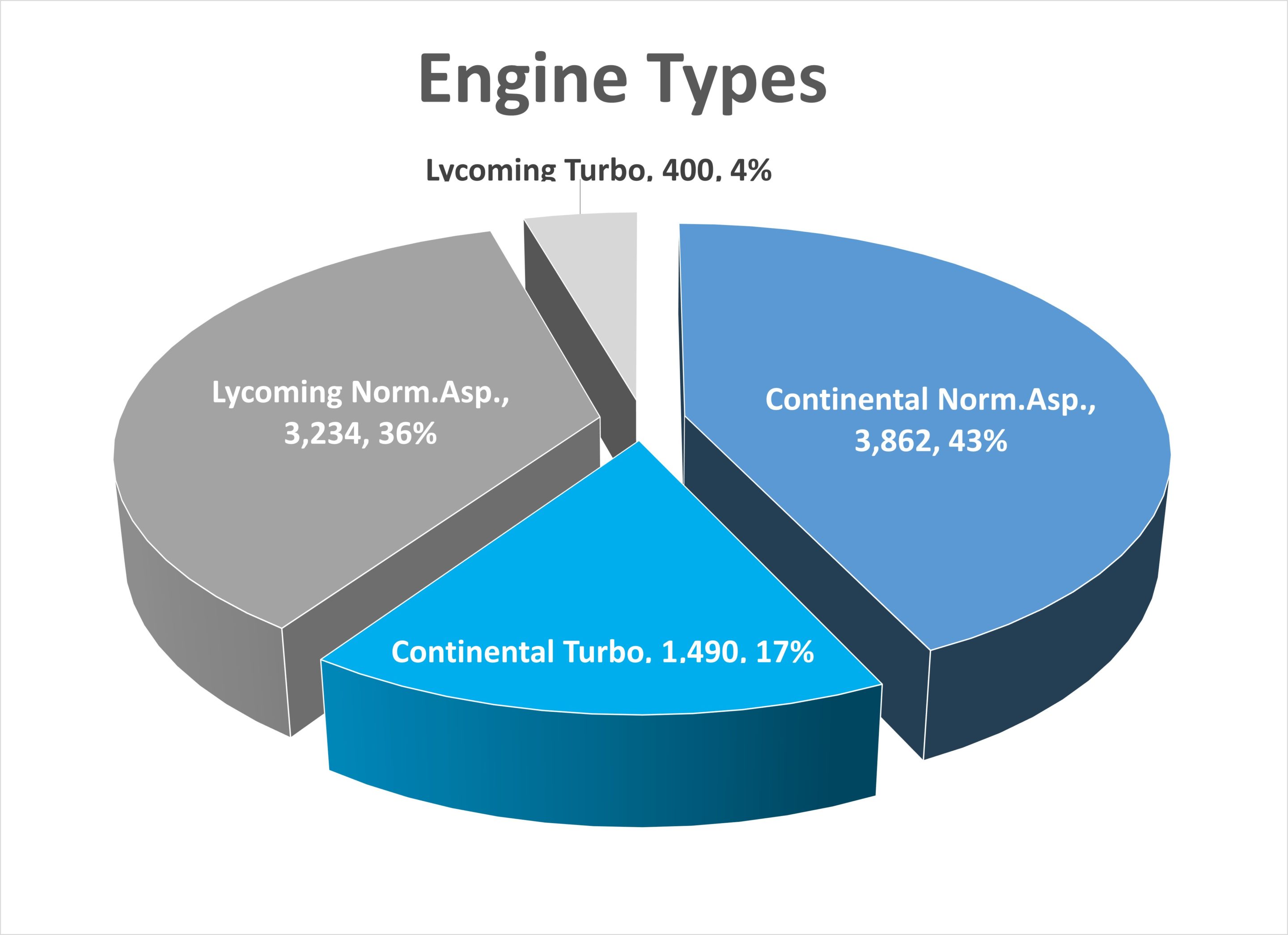

Fig. 2 – Breakdown by engine manufacturer and turbo vs. normally aspirated.

As shown in Figure 2, the roughly 9,000 exhaust valves we analyzed came from a well-rounded cohort of Continental and Lycoming engines. Most of the Continentals were big-bore six-cylinder engines—470s, 520s and 550s—and about one-third of them were turbocharged. The Lycomings were mostly smaller four-cylinder engines—320sand 360s—with some six-cylinder 540s. Turbocharged Lycomings were relatively rare.

Note that Figure 2 counts exhaust valves, not engines. Since most Continentals have six cylinders and most Lycomings have four cylinders, Lycoming engines were somewhat more numerous than the pie chart suggests.

HEAT DISTRESS

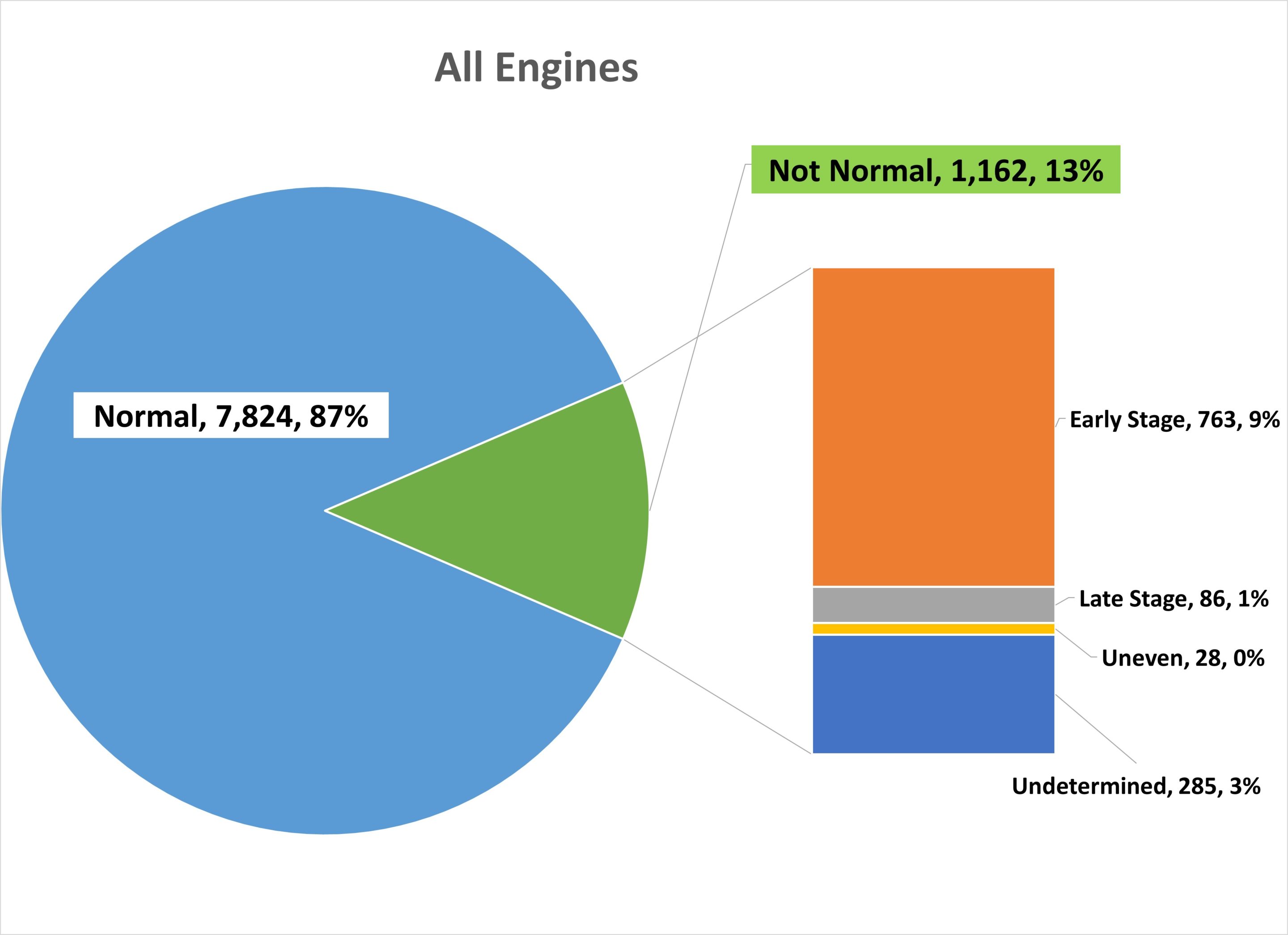

Fig. 3 – Exhaust valve heat distress classification (all engines).

Figure 3 shows the breakdown of heat distress findings among all 9,000 exhaust valves we analyzed. Approximately 87 percent of them were classified as normal, 10 percent heat distress, and 3 percent undetermined. Of the heat-distressed valves, 87% were early-stage, 10% were late-stage, and 3% were uneven.

Now, these numbers are pretty alarming if you do the math. Let’s be optimistic and assume that all the undetermined valve were actually normal, then the probability of a valve being normal would be about 90 percent. The probability that all valves in a four-cylinder engine are normal would then be0.90raised to the 4th power, or about 66 percent. For a six-cylinder engine, it would be 0.90 raised to the 6th power, or about 53 percent.

This means that the likelihood of having at least one heat distressed valve is about 34 percent for a four-cylinder engine and about 47 percent for a six-cylinder engine. Yikes!

But wait… There’s more!

CONTINENTAL VS. LYCOMING

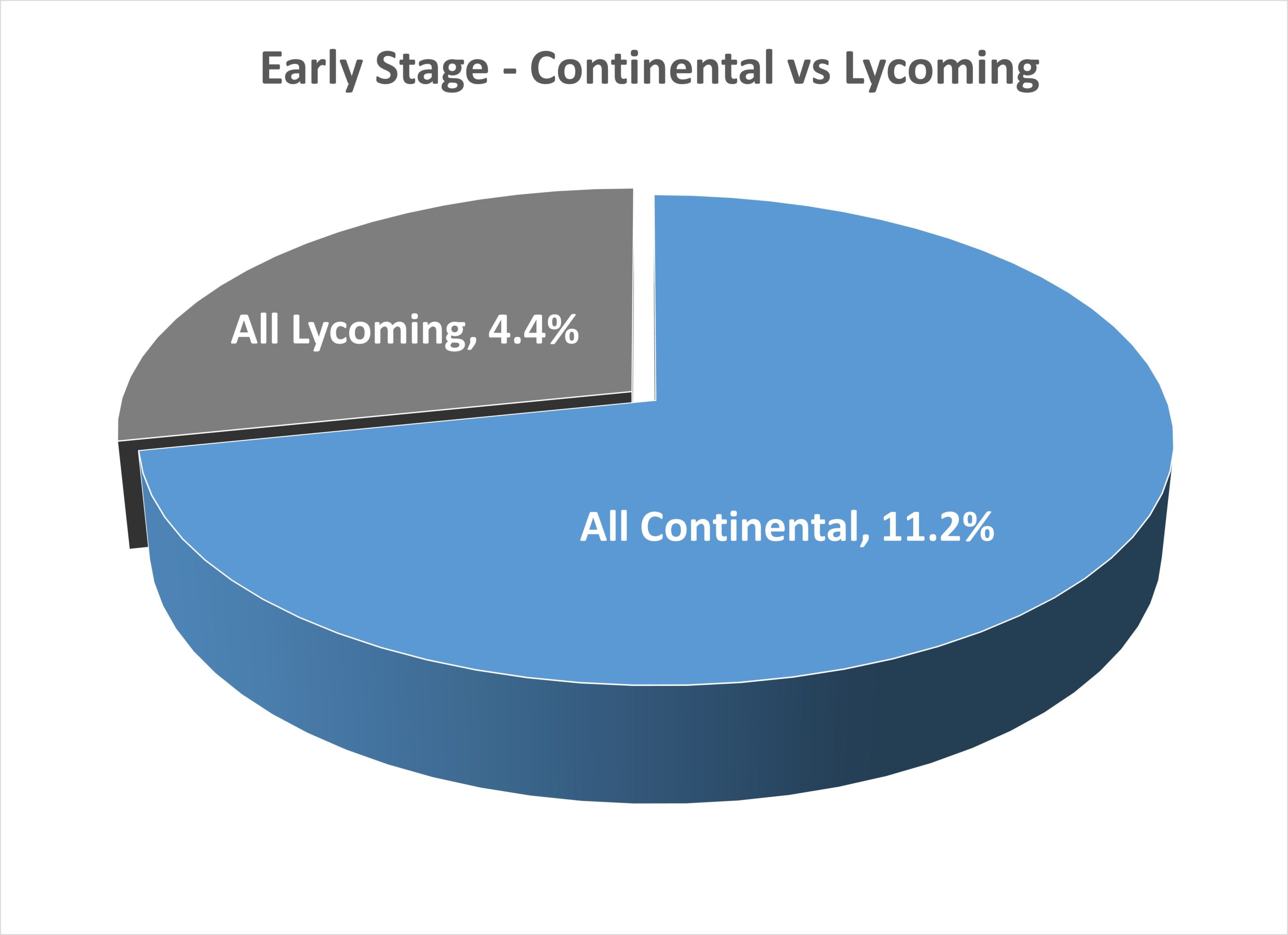

Fig. 4 – Early-stage heat distress, Continental vs Lycoming.

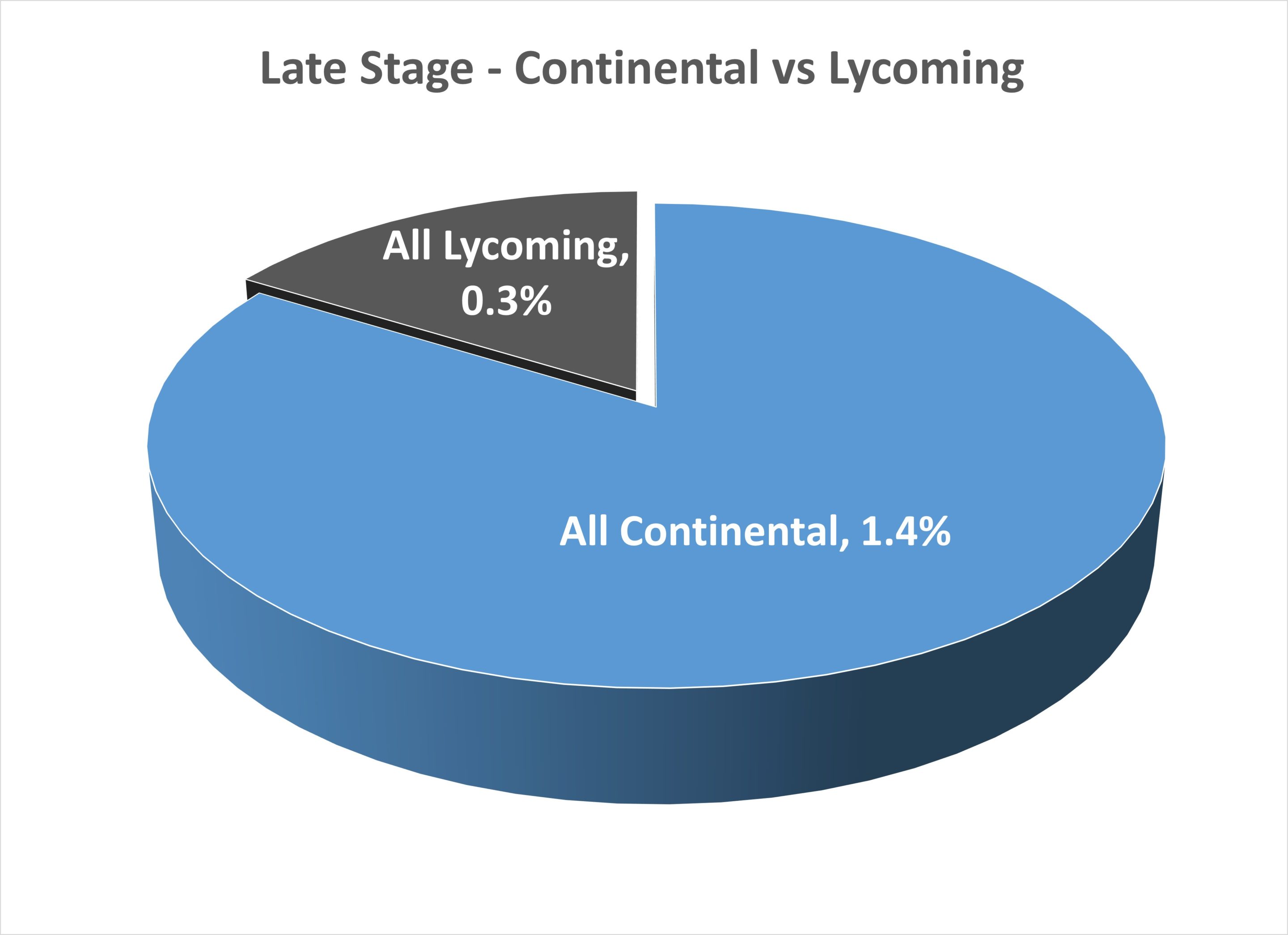

Fig. 5 – Late-stage heat distress, Continental vs Lycoming.

Figure 4 shows that Continental exhaust valves are about 2.5 times as likely to exhibit early-stage heat distress as Lycoming exhaust valves. Similarly, Figure 5 shows that Continental valves are about 4.7 times as likely to exhibit late-stage distress. That’s a huge difference, and really changes the risk calculations we did earlier.

For Continentals, there’s a 11.2 percent likelihood of a valve being in early-stage distress and a 1.4 percent chance of it being in late-stage distress. So the total probability of heat distress is 12.6 percent. Since almost all of the Continentals analyzed were six-cylinder engines, the likelihood of all six valves being healthy would be 0.874 to the 6th power, or 26 percent. This means the likelihood of a Continental engine having at least one heat-distressed valve at any given point in time is a staggering 74%. Good grief!

The good news is that 89 percent of the heat-distressed Continental valves are early-stage and so excellent candidates for lapping in place. Only 11 percent are late-stage that might require cylinder removal. The likelihood of a six-cylinder Continental having no late-stage valves on the verge of failing is 0.986 to the 6th power, or 91.8 percent. The chance of having at least one late-stage valve is 8.2 percent.

For Lycomings, the numbers are much better. Likelihood of early-stage distress is 4.4 percent and of late-stage distress just 0.3 percent. Total probability of heat distress is 4.7 percent. Most Lycomings are four-cylinder engines. So, the likelihood of having all healthy valves is 0.953 to the 4th power, or 82.8 percent. The chance of having at least one heat-distressed valve is 17.2 percent. The chance of having no late-stage valves is 0.997 to the 4th power, or 98.8 percent, and the chance of having at least one late-stage valve is only 1.2 percent.

That’s a huge improvement compared to Continentals. No wonder four-cylinder Lycomings have a well-deserved reputation for being bulletproof.

Why do Continental exhaust valves burn so much more frequently than Lycoming exhaust valves? The main difference is that Lycoming uses hollow-stem sodium-filled valves while Continental uses solid-stem valves. The result is that Lycoming exhaust valves have cooler heads and hotter stems than Continental exhaust valves. This accounts for the old saying “Continental valves burn, Lycoming valves stick.”

TURBO VS. NORMALLY ASPIRATED

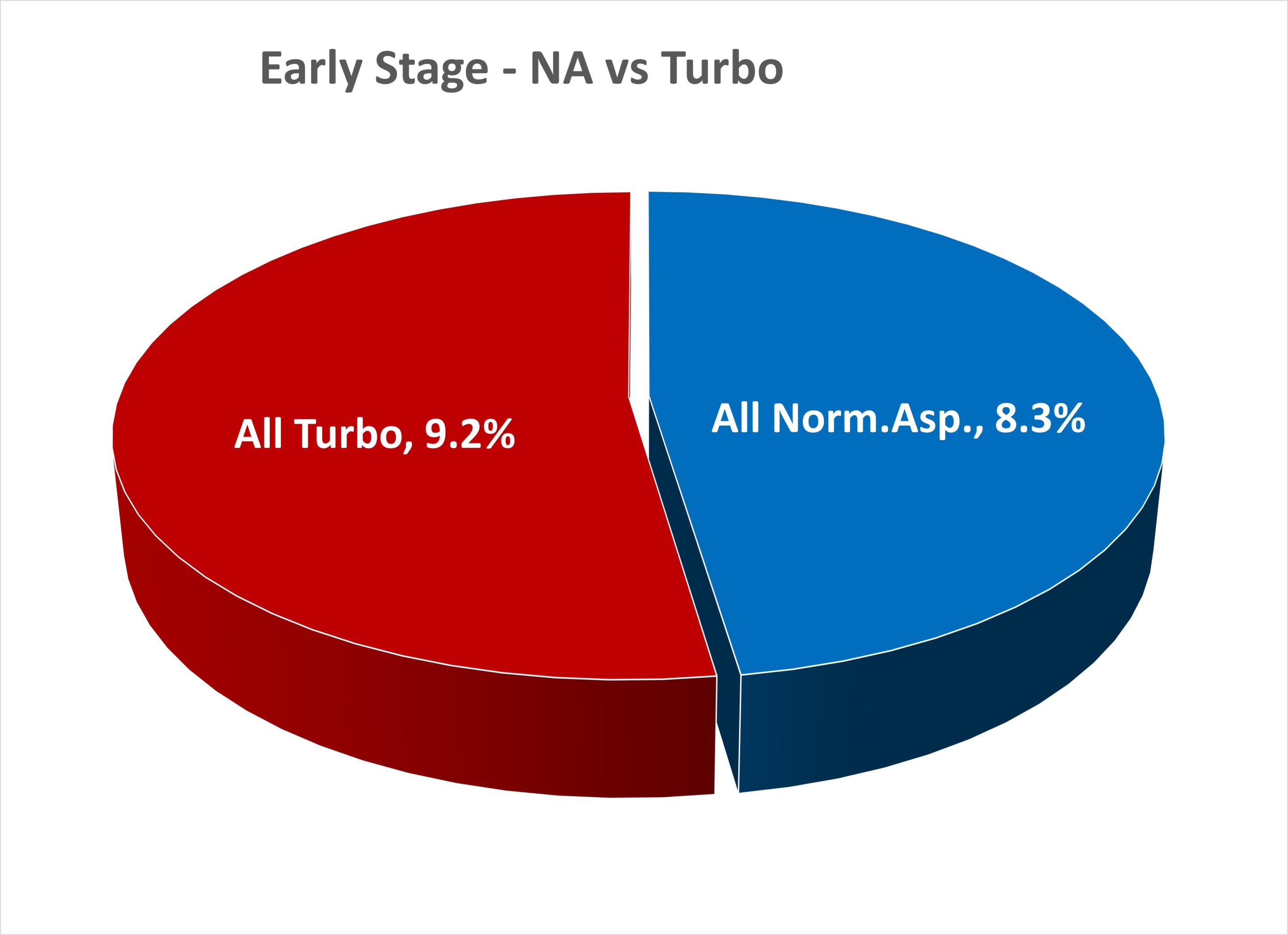

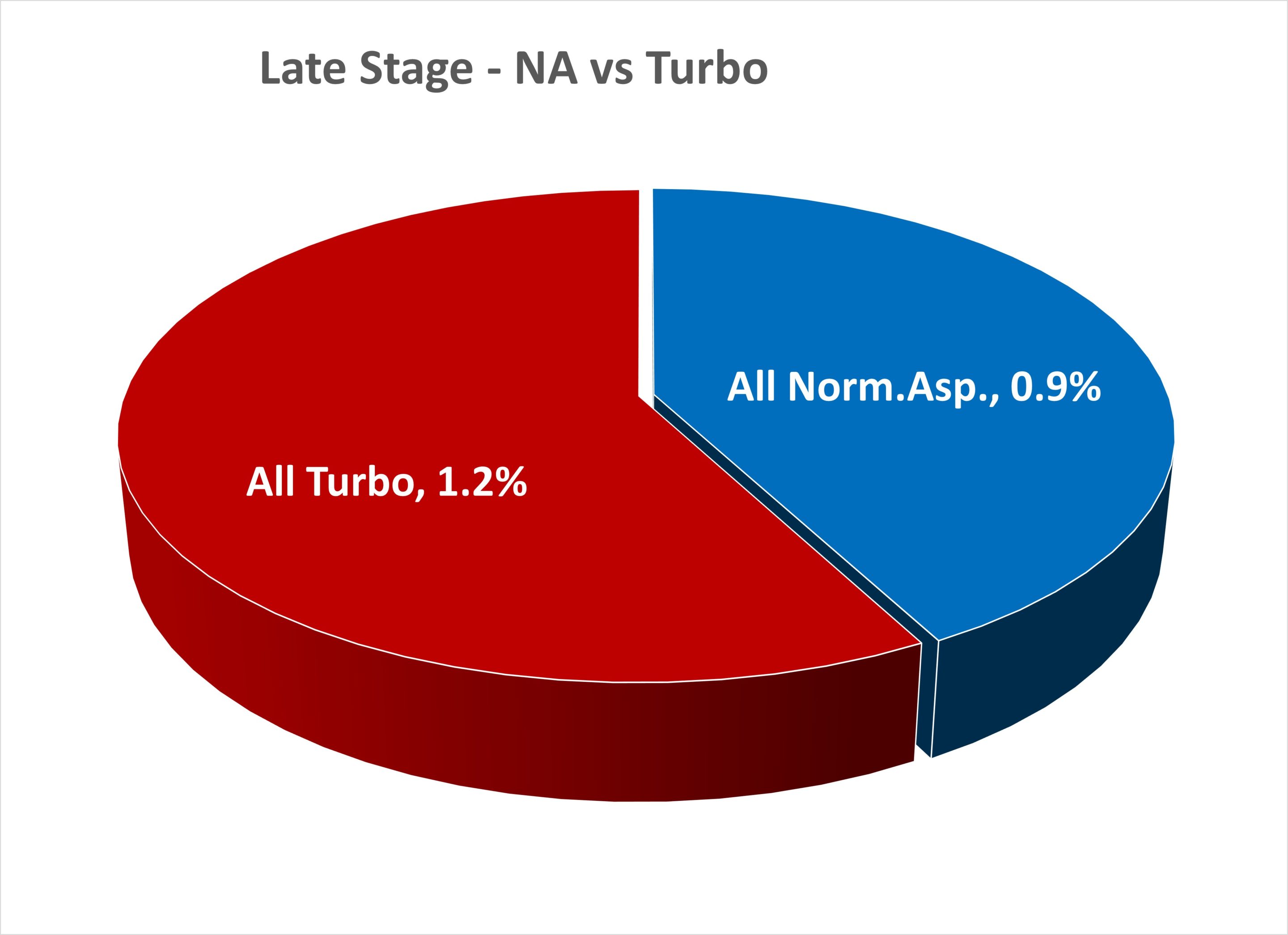

Fig. 6 – Early-stage heat distress, turbocharged vs normally aspirated.

Fig. 7 – Late-stage heat distress, turbocharged vs normally aspirated.

About one-third of the Continentals and a handful of the Lycomings were turbocharged. Since turbocharged engines tend to be “run harder,” you might expect that they’d develop more heat distressed valves than their normally aspirated brethren. Figures 6 and 7 show that this is true, but not by as much as you might think.

The incidence of early-stage distress is 9.2 percent for turbos and 8.3 percent for non-turbos. For late-stage distress, the numbers are 1.2 percent versus 0.9 percent. Combined, the overall heat-distress incidence is 10.4 percent versus 9.2 percent. Bottom line is that turbos burn valves more often, but only slightly.