An exhaust valve failure can be a dangerous and expensive event

FEVA meticulously analyzes data for early indicators of exhaust valve failure.

This powerful feature on the Savvy platform has scanned data from over five million uploaded GA flights for telltale signs of a burned exhaust valve. To date, FEVA has preemptively identified hundreds of failing valves before they become a costly safety of flight issue.

At Savvy Aviation, our goal is to equip pilots with cutting-edge tools to keep their plane safe, reliable, and legal, so as technology evolves so do our offerings. Since its inception in 2014, FEVA has undergone three advancements (FEVA 1.0, FEVA 2.0, and now FEVA 2.1). FEVA 2.1 incorporates more predictive variables from an aircraft’s recent flight history, resulting in more accurate, sensitive, and consistent predictions.

To learn more about this technology, see the FAQs below.

Transform your approach to aircraft maintenance by receiving FEVA reports. Get started by enrolling your aircraft in SavvyBasics, SavvyAnalysis, SavvyQA, or SavvyMx. Click the button below to see which plan is right for you:

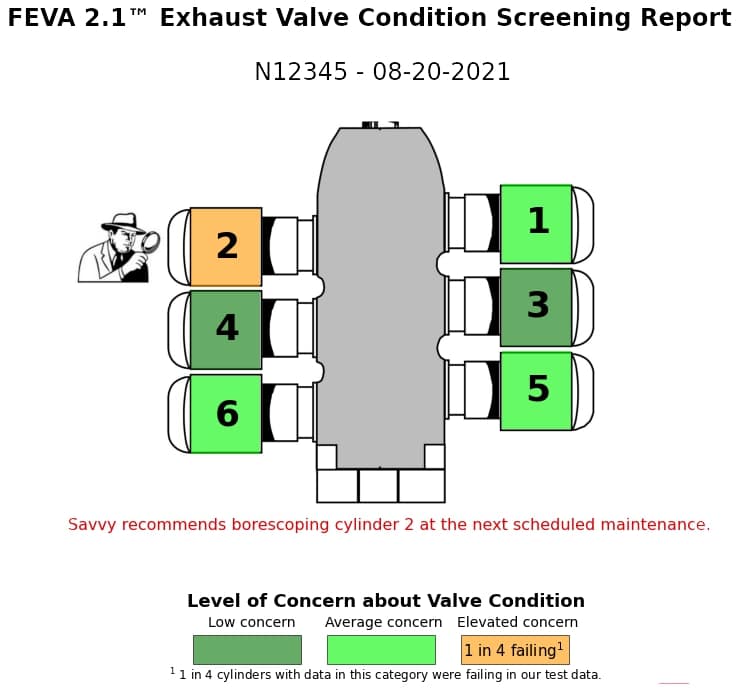

In the above report, FEVA 2.1 has predicted that cylinder #2 has an above-average risk of exhaust valve failure. We would strongly recommend doing a borescope inspection of the #2 cylinder as soon as possible to determine the actual condition of the exhaust valve.

FAQs

NOT READY TO ENROLL?

TRY SavvyFree.

Savvy clients at every level have access to The Savvy Platform – The world’s leading software for analyzing information gathered from piston aircraft data monitors.

Self-analyzing your engine data for free using the same powerful analytical tools our professional data analysts use with SavvyFree.