Few aviation maintenance tasks are so misunderstood—and so responsible for inappropriate work and expense—as the routine differential compression test.

It happens every year: We put our aircraft in the shop for its annual inspection. The IA pulls out the compression test gauges and measures each cylinder while we hold our breath and pray silently until the verdict is rendered. If the readings are good, we can smile and relax; if not, we brace ourselves for the inevitable sticker shock.

I learned an important lesson about compression tests in Spring of 2002, shortly after I became an A&P, when I did something dumb: I pulled a perfectly good cylinder off of my engine!

Had I known what I know now, I wouldn’t have touched that cylinder. But at the time, I thought I was doing the right thing. (It does seem like most of the wisdom I’ve gained over the years came from first exhausting all other alternatives.)

I had downed my airplane for its 2002 annual inspection, and the first items on my checklist were to drain the hot oil and perform a hot compression test. All cylinders measured in the 70s except one; that one measured 60/80 with air obviously leaking past the exhaust valve.

At the time the applicable guidance was TCM Service Bulletin M84-15. That SB instructed mechanics that it was okay for a jug on a Continental engine to leak lots of air past the rings (or what TCM called the “dynamic seal”) and still be airworthy, but that NO leakage past the valves (“static seal”) was permissible.

My cylinder clearly was leaking at the exhaust valve. So off it came.

Pulling the jug was a PITA. It took me 2+ hours to remove the cooling baffles, exhaust and induction manifolds. It took another hour to remove the rocker cover, rocker shafts, rocker arms, pushrods and pushrod housings. Finally, I used cylinder base wrenches, a big breaker bar, and considerable brute force to coerce the eight cylinder base nuts loose. Four hours into the project, I held the offending jug in my arms and carried it over to my workbench to survey the damage.

(Today, I’d survey the damage with a borescope and know exactly what was going on in 15 minutes flat without having to go through all this agony. But back in those bad old days, aviation borescopes cost $20,000 and were used mostly for turbine engine hot-section inspections.)

I inspected the cylinder carefully, with special attention to the exhaust valve. Try as I might, I couldn’t find anything wrong with it. The cylinder looked normal. The exhaust valve looked fine, with no evidence of heat distress or metal erosion. The valve seat looked fine, too.

I was frustrated. After all this time and effort, I wanted to see a smoking gun. I couldn’t find one.

I drove over to the local cylinder shop. They examined my cylinder and couldn’t find ayything wrong either. On general principles they dressed the seat, replaced the exhaust valve, gave the barrel a light hone to restore the crosshatch pattern, and gave me an invoice for $500 and change.

I installed a new set of rings on the piston, then re-hung the cylinder and reinstalled all the stuff I’d previously had to remove. By the time everything was back together I had about 10 hours of sweat equity into the project, plus about $800 in parts and outside work. (If I hadn’t been doing the work myself, I’d be out the better part of two grand.)

Terrible timing

That sordid affair turned out to be a classic case of bad timing. Nine months later, TCM radically changed its guidance about when a cylinder should come off. On March 28, 2003, the wizards of Mobile issued Service Bulletin SB03-3 titled “Differential Pressure Test and Borescope Inspection Procedures for Cylinders.” This new 14-page service bulletin explicitly superseded M84-15, and differed from it in two crucial respects.

First, SB03-3 completely did away with the earlier distinction between leakage past the “dynamic seal” and the “static seal.” Under the new guidance, compression is permitted to be as low as the mid-40s, and there’s no distinction whether the leakage is past the rings or the valves.

Second, SB03-3 requires that mechanics perform a borescope inspection of the cylinder in conjunction with each compression test. It explains that this doesn’t require a fancy $20K aviation-grade borescope, and recommends using a simple rigid automotive-grade borescope that costs less than $1K. SB03-3 says that if the cylinder looks good under the borescope, the mechanic should not remove the cylinder regardless of how low its compression is. Instead, SB03-3 directs the mechanic to try several tricks (such as “staking the valves” and rotating the prop backwards) to obtain a better compression reading. If that still doesn’t raise the reading to an acceptable value (typically mid-40s or higher), then SB03-3 says that the aircraft should be flown “for at least 45 minutes” and then the compression test be repeated, hot.

The fundamental message of SB03-3 is that the compression test is not a reliable way of assessing cylinder condition, and that the borescope inspection is much more reliable. If a jug flunks the compression test but looks good under the borescope, then the compression measurement must be considered suspect, and heroic measures should be taken to raise it before a decision is made to pull the jug.

Obviously those wizards in Mobile who drafted SB03-3 already knew what I’d just learned the hard way. Had they issued SB03-3 a year earlier, I’d have never yanked that jug. Live and learn.

Nowadays, my company manages the maintenance of nearly 500 piston airplanes, more than 80% of them Continental-powered. We always ask that the shops performing annual inspections on “our airplanes” follow the guidance of SB03-3 to the letter. We want every cylinder be borescoped at every annual—something very few shops do unless we request it explicitly. If a cylinder looks good under the borescope, we move heaven and earth to make sure it isn’t removed, no matter what the initial compression test says.

Compression testers often lie. Borescopes never do.

Case in point

Last week, for example, I was approached by an aircraft owner who just put his airplane into the shop for its annual inspection, and was presented with a $31,000 repair estimate. This was a first-rate shop, one that I’d worked with many times. This shop had also performed the last two annual inspections, and on both occasions the invoices came to about $25,000. The owner figured that after two $25K annuals, this one ought to be uneventful. When he received the $31K estimate, he panicked and called me for help.

I asked the owner to email me the $31K estimate and the two $25K invoices, and reviewed them in detail. It was obvious the aircraft did have some significant airworthiness issues, including a leaking turbocharger and a wastegate worn beyond repair limits. Clearly those would need to be dealt with.

But about half the $31K estimate came from the shop’s recommendation to do a “top overhaul” of the engine, with all six cylinders being replaced with new ones. The work order showed that two cylinders had compressions in the high 30s (below the no-go limit), two others were in the low 40s (just above the limit), and two were very respectable (including one that had been replaced only two years ago). The work order said nothing about where the cylinders were leaking (rings or valves) or what they looked like under the borescope.

I phoned the shop’s Director of Maintenance to discuss the top overhaul recommendation.

Where were the cylinders leaking? Exhaust valves.

What did the valves look like under the borescope? They looked fine.

I walked through the SB03-3 protocol while the DOM followed along on his printed copy. By the end of our conversation, the DOM concurred that four of the six cylinders were airworthy, and agreed to have the airplane flown for an hour and then re-check the other two hot under his personal supervision.

A few days later, we spoke again. The DOM advised me that on the re-test, both cylinders measured about 10 points higher than the no-go limit and would be signed off as airworthy. The shop’s original “replace them all” recommendation morphed into “all cylinders airworthy, no work required.” I just love when that happens.

Scoping the jug

The borecope is a much more reliable tool for assessing cylinder condition than the compression gauge. Yet the differential compression test—which dates back to World War II—refuses to die. It’s written right into the FARs (Part 43 Appendix D) so mechanics are still required to do it at every annual inspection, despite the fact that it has arguably outlived its usefulness.

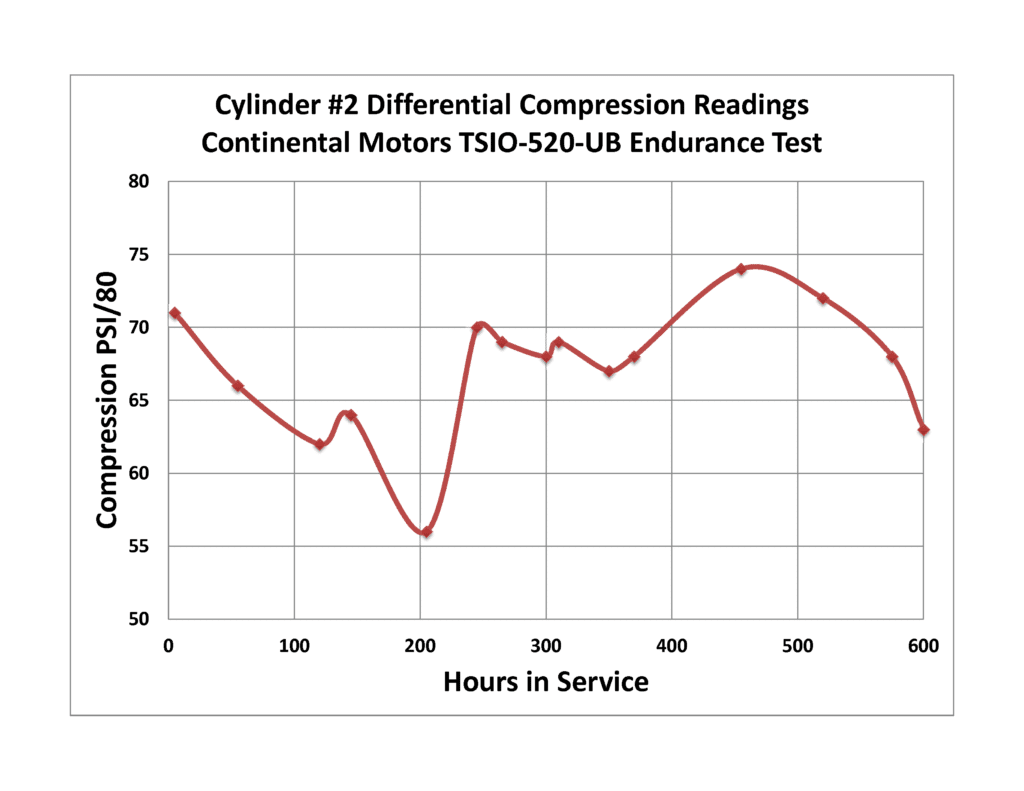

One reason for this, I think, is because the compression test produces a numerical score that gives the illusion of precision. (It’s an illusion, because compression readings are notoriously non-reproducible, and can vary all over the place as illustrated in Figure 2.) In contrast, the borescope inspection requires a subjective evaluation of what the IA sees through the ‘scope, and that requires some training, experience and judgment.

Few A&Ps are adequately trained in how to interpret what they see through the borescope. It’s not currently taught in A&P school. I haven’t been able to find any textbooks or training materials on the subject. Anything an A&P knows about borescope inspection has been learned through on-the-job training.

The value of a borescope inspection depends on whether the IA knows what to look for. Some do; others are clueless.

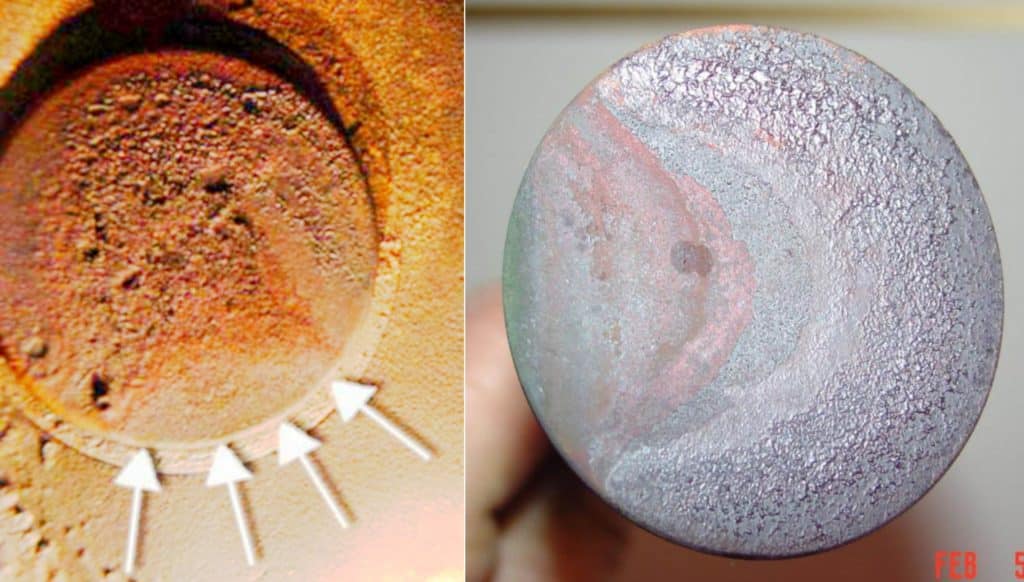

Figure 3—A healthy exhaust valve has a symmetrical appearance under the borescope. These don’t. The valve on the left has a hot spot in the 5 o’clock position, and needs to be replaced soon. The one on the right has a profound hot spot in the 9:30 position and was probably just 5 or 10 hours from failing.

That’s not to suggest that borescope inspection is difficult. You can learn most of what you need to know in about 30 minutes, simply by looking at a bunch of borescope images of good cylinders and bad cylinders until you learn to recognize what a bad one looks like. It’s not rocket science.

The most important thing to learn is how to detect a failing exhaust valve, because exhaust valve failure is by far the most common safety-of-flight failure mode for cylinders. It’s easy to tell the difference between a healthy exhaust valve and an sick one: A healthy exhaust valve has a symmetrical appearance under the borescope—rather like a bullseye—indicating that it’s operating at a uniform temperature around its entire circumference. A sick exhaust valve has an asymmetrical, lopsided appearance (see Figure 3) that shows the valve has a hot spot. The hot spot will get progressively worse until the valve fails catastrophically in-flight and shuts down the cylinder.

Figure 4—The Snap-On BK8000 is an example of the new generation of low-cost digital borescopes capable of capturing high-quality digital images. It costs less than $1,000.

Lack of adequate mechanic training has hampered the acceptance of borescopy as the gold standard for assessing cylinder condition. But I’m optimistic that in time it will supplant the old compression test. One encouraging development is the introduction of a new generation of low-cost digital borescopes like the $995 Snap-On BK8000 capable of capturing high-quality digital images. (See Figure 4.) This ability to capture digital images means that mechanics in the field no longer need to be experts in borescopy; they can capture images and send them over the Internet to someone capable of providing expert interpretation, much as a radiology technician captures CT or MRI images and passes them to a radiologist for interpretation. As more shops retire their old optical scopes and replace them with new digital ones, I expect this increasingly will become how cylinder evaluation will be done. At least I hope so.

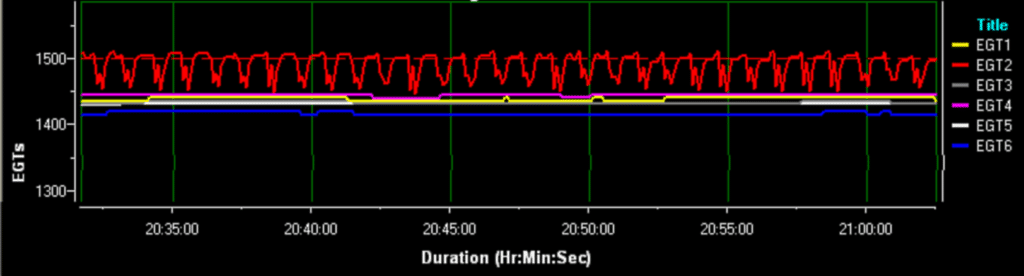

Another encouraging development is the proliferation of digital engine monitors that instrument individual cylinder CHT and EGT values (and often other key engine parameters), capture the values every few seconds, and permit the data to be dumped and analyzed. Almost all new-production piston aircraft are factory-equipped with such monitors, and I estimate that nearly half of the legacy fleet is now so-equipped. All sorts of cylinder problems—including failing exhaust valves—can be readily detected and diagnosed through engine monitor data analysis. (See Figure 5.)

What about Lycomings?

A decade ago, Continental literally “rewrote the book” on evaluating cylinder condition when they issued SB03-3. If we could just persuade our IAs to follow its guidance—and rely more on the borescope than the compression tester—we’d eliminate the epidemic of inappropriate top overhauls and unnecessary cylinder removal that has plagued piston GA for as long as I can remember.

But what if you fly behind a Lycoming?

Lycoming’s equivalent to SB03-3 is Service Instruction 1191A. It’s just two pages long, and makes no mention borescopes or engine monitors or any of the things we’ve learned about cylinder evaluation over past 50 years. It perpetuates the WWII-vintage notion that compression readings of 70/80 or better are satisfactory, readings below 65/80 are worrisome, and readings below 60/80 are unacceptable.

If you own a Lycoming-powered aircraft, this service bulletin is bad news and will cost you a lot of money.

The good news—if there is any—is that guidance in Lycoming S.I. 1191A is couched in “squishy” language. It doesn’t say that a cylinder that measures less than 60/80 “must be removed.” It says removal and overhaul of such a cylinder “should be considered.” This gives your IA wiggle room, if he’s brave enough to take it.

But don’t be surprised if he isn’t.

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: