A mechanical problem away from home is every aircraft owner’s worst nightmare. Here’s how one owner dealt with such a nightmare…with a little help.

On an otherwise-peaceful Saturday morning, I received a panicky text message from Mark, a Cessna 185 owner from the San Francisco Bay Area. Mark said that he and his wife had flown to Minden, Nevada in their beautiful Cessna 185 to take care of an ill relative. A couple of days later, when Mark started the aircraft to depart for home, the engine registered no oil pressure.

The Cessna has the original factory-installed direct-reading oil pressure gauge — no electrons or connectors or data acquisition modules involved — so if the gauge reads zero, you can pretty well take it to the bank that there really is no oil pressure. And that’s not a great way to begin a Saturday morning.

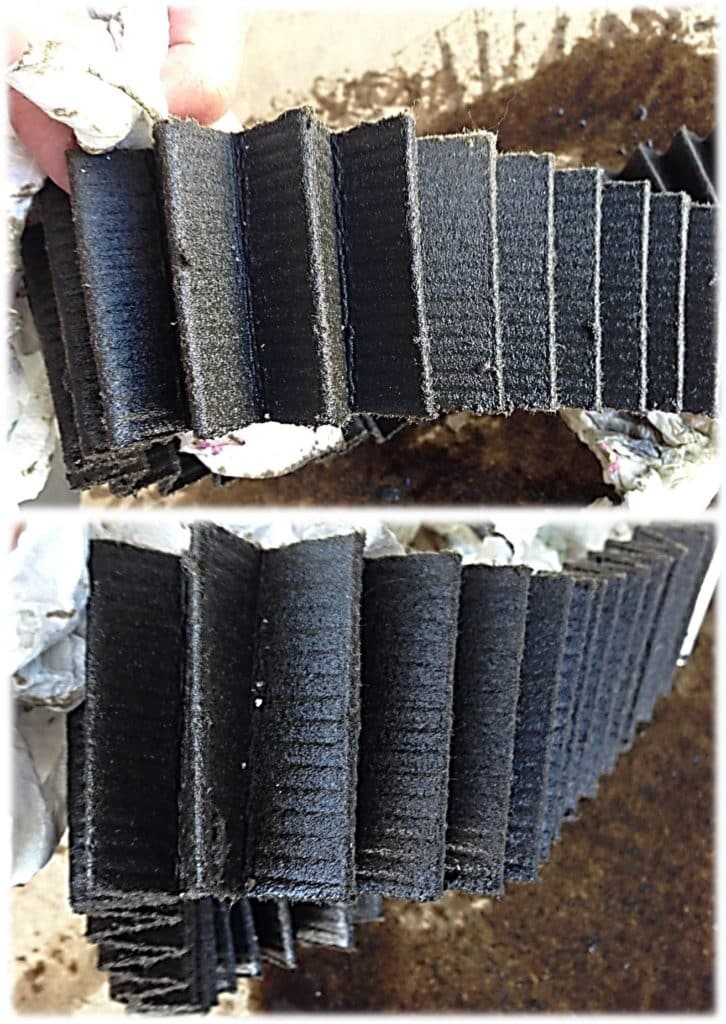

Mark took the aircraft to the local A&P on the field, who plumbed an external pressure gauge to the engine, started it briefly, and verified that indeed there was no oil pressure. The A&P then cut open the oil filter, and informed Mark that there was “significant bearing metal” in the filter, and that the engine would need to be removed and shipped to an engine shop for a “bottom-end teardown.” The mechanic disappeared into his office for a few minutes, and emerged with a written estimate for the engine removal, teardown and re-installation that totaled something north of $10,000.

That’s when Mark texted me, looking for a second opinion.

Remote diagnosis

I asked if Mark could send me some high-resolution photographs of the metal that the mechanic found in the oil filter. He snapped a series of nice photos with his iPhone and “texted” them to me. When I reviewed the images, it looked to me as if there were only a few small flecks of metal in the filter. I saw nothing that I would consider to be “significant.” Certainly nothing “significant” enough for me to conclude the engine needed to be torn down before further flight (a rather drastic diagnosis).

I asked if Mark was sure there’s enough oil in the sump, and he assured me that was the first thing he checked. I explained that by far the most likely reason for a loss of oil pressure (other than not enough oil) was contamination of the oil pressure relief valve. The oil pressure relief valve is located on the back of the oil pump, and it regulates engine oil pressure. It’s a dead-simple device, consisting of a steel plunger that is spring-loaded to press against a seat, and has an adjustment screw that controls the spring tension. I suggested that Mark ask the A&P to remove the oil pressure relief valve housing and inspect the valve for the presence of foreign material that might be preventing the plunger from making good contact with the seat.

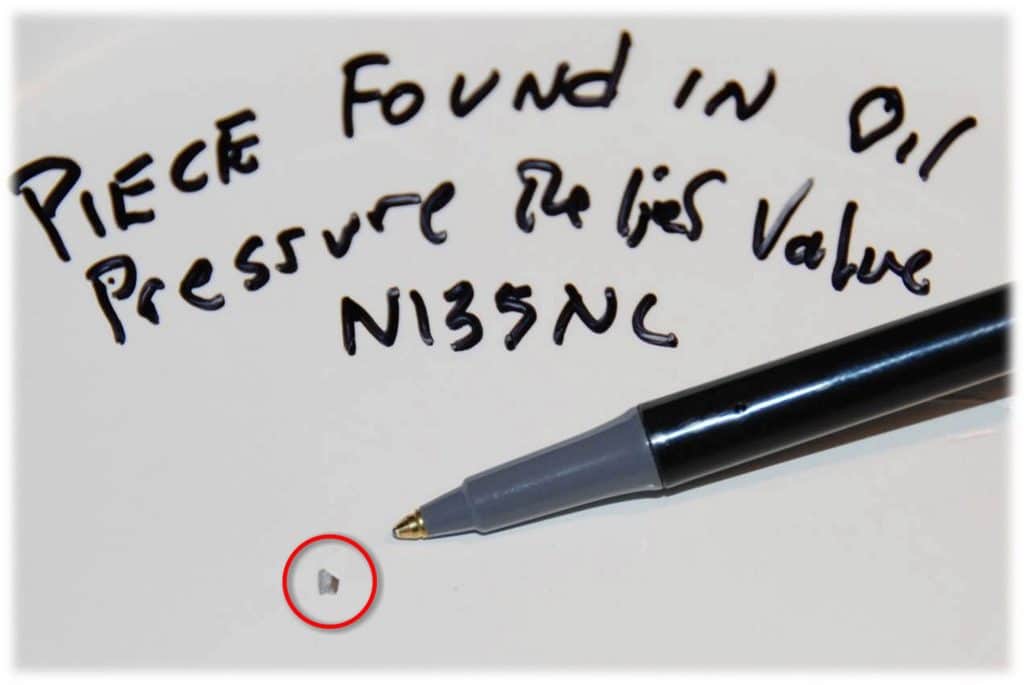

A half-hour later, Mark texted me another photo showing a small metal particle that the mechanic found lodged in the oil pressure relief valve. I inquired whether nor not the piece of metal was ferrous (i.e., would stick to a magnet). Mark checked it with a magnet and reported that it was nonmagnetic. Based on that fact, and the apparent color of the piece of metal (which we both agreed was “silvery” and not “coppery”), we concluded that it was almost certainly a small chunk of aluminum. I estimated its size as roughly 1/32 of inch in diameter, give or take.

I told Mark that I was not terribly concerned about this tiny chunk of aluminum “unless there are a bunch of its brothers and sisters floating around in your oil pan.” At the same time I was texting this to Mark, the local A&P was telling him that this finding was just one more indication that the engine really needs to be torn down before further flight.

Hostage situation?

At this point, Mark was understandably starting to freak out.

“What can I do?” texted Mark.

“Can this mechanic ground my airplane?”

“Can he hold it hostage until I agree to the teardown?”

I did my best to calm Mark’s fears. I asked him a few more questions, and learned that he was pretty handy with tools and accustomed to doing his own oil changes and other preventive maintenance. I also learned to my delight that Mark had read my article from the mid-90s titled “The Traveling Tool Kit” and carried an excellent collection of tools and spare parts in his Cessna 185. Armed with this knowledge, and given the fact that the local A&P was obviously fixated on tearing down Mark’s engine, I concluded drastic action was necessary.

I advised Mark to instruct the local A&P to put his airplane back together and give him a logbook entry for the work he’d performed so far, to pay his invoice, and get his airplane the heck out of there before “Mr. Teardown” had a chance to take anything else apart.

Mr. T was obviously not pleased about this. He agreed to put the oil pressure relief valve back together, then started the engine and verified that it was now registering oil pressure (as I was sure it would). He insisted on being paid by cashier’s check before he would release the aircraft, and gave Mark a logbook entry that made it clear he was releasing the aircraft against his better judgment.

Free at last

After successfully extracting his aircraft from Mr. T’s shop, Mark taxied over to the FBO and asked if he could use their hangar. They said he could. Following my advice, Mark drained the oil through several layers of cheesecloth, which he then inspected carefully and reported to me that there was no metal visible. Mark texted me another iPhone photo that showed oily cheesecloth in a funnel with nothing “interesting” in it.

I had Mark service the engine with fresh oil, cowl it up, and perform a 30-minute ground run, varying the RPM between 1,000 and 1,700. He reported to me that oil pressure started a bit above the green arc, but as the oil temperature came up the pressure stabilized at 50 PSI, exactly where it should be. I then had Mark perform performed a “high-speed taxi test” at full takeoff power on the long 7,400 foot runway.

After taxiing back to the FBO, Mark uncowled the engine and cut open the oil filter. It was absolutely spotless, with no signs of metal whatsoever. He installed a new oil filter and cowled everything back up.

“I’m comfortable with you flying the airplane now,” I texted Mark. “Are you comfortable?” He texted back that he was.

By now, it was late afternoon. Mark proceeded to take off from Minden and fly to the next airport up the valley, Carson City, where he wisely decided to remain overnight. The short flight was completely uneventful and the oil pressure was rock solid from takeoff to touchdown. After landing, he texted me three more photos, one of the oil pressure gauge with the needle two-thirds of the way up the green arc, a second of the big sign saying “Welcome to Carson City,” and a third of his beautiful Cessna 185 on the tie down at Carson airport.

Don’t you just love it when a plan comes together?

Mark’s plan was to take off first thing in the morning and cross the Sierra into California, following the freeway just to be on the safe side. I advised him to keep a close eye on the oil pressure gauge and if he sees any fluctuation at all in-flight, he should land the airplane as soon as practical and holler at me for help. I didn’t expect that to happen, of course—by this time, I was as certain as I could possibly be that there is nothing at all wrong with his engine.

Late the next day, I received this text message from Mark: “Hi Mike! The plane flew beautifully home from Carson. I followed I-80 through Reno, Truckee, and on to my home base at Byron.” And I breathed a sigh of relief.

Mark’s experience with the local A&P is unfortunately very common. Way too many A&P mechanics are spring-loaded to the “tear it down” position. Instead of practicing “reliability-centered maintenance” the way I try to do, they practice “liability-centered maintenance.” If you ever find yourself in such a situation, don’t be intimidated. Get a second opinion.

Post mortem

I shared the story of Mark’s AOG ordeal with some fellow aircraft owners and received the predictable knee-jerk reaction: “The A&P’s actions bordered on criminal! This shop should be put out of business!”

I don’t agree that the mechanic’s actions “bordered on criminal.” They were not even unusual. In my experience, many A&Ps would do exactly what this one did, especially given that Mark was a perfect stranger and his airplane was a transient visitor.

It was a good thing that this shop was in business. If it hadn’t been, how would the Mark have gotten the relief valve cleaned and gotten his oil pressure restored? The local A&P was clearly a competent wrench swinger (if not a world-class diagnostician), and it was sure lucky for Mark he was on the field and even willing to work on Saturday! Maintenance shops are few and far between in remote areas like this, and we sure don’t need any fewer of them.

Most A&P mechanics are scared to death of being sued. And in the incredibly litigious environment that followed the passage of GARA in 1994, they should be scared. There has been an explosion of lawsuits against shops and mechanics. Even a lawsuit with no merit can be punishingly expensive for a shop or mechanic to defend. These are typically not high net worth individuals, and many of them have no insurance or marginal insurance.

Let’s face it: There aren’t many A&P’s who would be willing to go out on a limb the way I did for this Cessna 185 owner that I didn’t know from Adam. Think about the consequences for me if Mark were to crash on the flight home. His widow’s attorney would be all over me like white on rice. Very, very few A&Ps would be willing to take the kind of risk that I did, and frankly I don’t blame them one bit. (And yes, I did breathe a big sigh of relief when I heard that Mark and his beautiful airplane were safely home.)

My purpose in relating Mark’s story is not to condemn the local mechanic (who is probably a very good mechanic, albeit understandably risk-averse). It is to teach a lesson about the nature of the maintenance infrastructure for these airplanes that every aircraft owner has to deal with.

If an owner is not sure what maintenance should or should not be performed, he should always seek an expert second opinion from someone he trusts. This is especially important when the owner has a problem away from home and is dealing with strangers whose skills, judgment and attitude are unknown.

Epilog

Not long after Mark got his airplane home, I recommended that he take it to a very good Cessna service center in Northern California for its annual ordeal. In the course of the annual inspection, the shop found exactly where that little chunk of aluminum in the oil pressure relief valve had come from. It turned out that the oil filter adapter’s jam nut had worked loose, and the adapter was vibrating and chewing up the threads in the aluminum oil pump housing. (This problem is so commonplace that there’s a recurring AD against the oil filter adapter.) The shop installed a new pump housing and oil filter adapter. Mystery solved!

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: