A mechanical problem away from home is every aircraft owner’s worst nightmare. Here are some thoughts about how best to deal with one.

As a tech rep for the three largest airplane type clubs in the world (ABS, CPA, COPA) and as the founder and CEO of the world’s largest professional maintenance management firm for owner-flown aircraft, I’ve helped guide thousands of aircraft owners through challenging troubleshooting scenarios, difficult annual inspections, major structural repairs, engine overhauls, and just about every other kind of maintenance event that can befall an airplane. But of all of these, the ones that invariably elicit the most gratitude have been those where I’ve been able to help an aircraft owners deal with a mechanical breakdown away from home.

Here’s what one of my managed-maintenance clients emailed me recently:

“I always appreciate it when you guys save me money on my annual inspection and other routine maintenance. But when you helped me out with that charging system failure during my recent fishing trip to Montana, that was truly priceless!”

After having dealt with a goodly number of breakdown assistance situations over the years (including a few involving my own airplane) and having seen both good outcomes and bad ones, I’ve arrived at three golden rules for dealing with aircraft breakdowns away from home:

- Don’t put the aircraft in a shop until you’ve diagnosed the problem, or at least taken fault isolation as far as you can.

- Don’t do maintenance away from home base if you can possibly and prudently avoid it. If the problem is one that doesn’t compromise safety-of-flight, it’s almost always best to fly home and deal with the issue there.

- If maintenance away from home is unavoidable, do the absolute minimum necessary to fly home safely, and defer the rest until after you get home.

My underlying philosophy here is “owner first, airplane second.” When an aircraft is away from home base and the owner encounters a mechanical issue, the first priority should always be to get the owner back in the air as quickly as possible, not to get the airplane fixed as thoroughly as possible. If a careful diagnostic evaluation reveals that the aircraft can be flown home safely without putting it in a shop away from home, that’s almost always the best possible outcome.

To illustrate this point, let me tell you about two different real-life mechanical breakdown events that occurred recently to two different owners of two nearly identical airplanes. They took place only about one week and 200 nm apart, but the outcomes couldn’t have been more different from the owners’ points of view.

Case #1: Loss of MP

On Friday, the owner of a gorgeous 2010 Cirrus SR22 Turbo retrieved his airplane from a busy factory authorized service center at the completion of its very first annual inspection since leaving the Cirrus factory. Two days later, on Sunday morning, the Arkansas-based owner loaded his wife and kids into the airplane and departed on an 800 nm IFR flight plan to Kissimmee Gateway Airport, Florida, for a family mini-vacation at Disneyworld.

The owner-pilot climbed to his flight-planned altitude of FL190, programmed the state-of-the-art Garmin Perspective avionics, put the digital autopilot into nav-track and altitude-hold, tuned in his favorite Serius-XM music channel, and settled back to enjoy the crystal clear silky smooth air and 220-knot groundspeed readout, and thinking “aviation doesn’t get much better than this.”

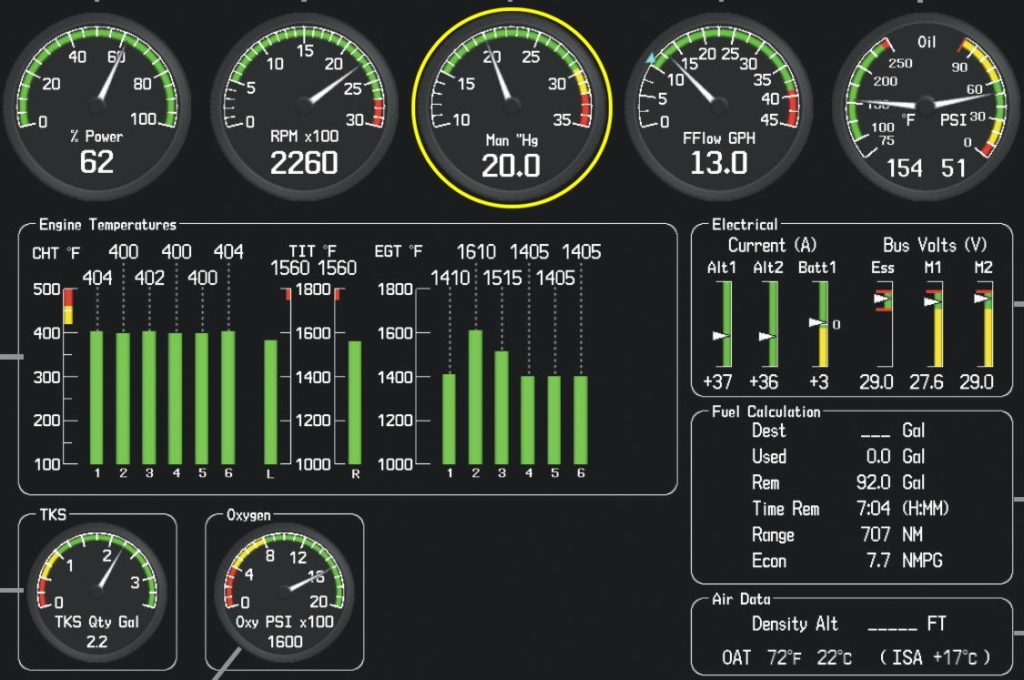

A bit more than halfway to Kissimmee, however, the pilot sensed a loss of power and airspeed, and realized that there had been an uncommanded drop in manifold pressure from the expected 30 inches to something much less. He quickly scanned the information-rich engine data page on his MFD and determined that all other engine parameters—CHTs, EGTs, oil pressure and temperature, fuel flow, etc.—were within acceptable limits. It seemed as if the airplane’s turbocharged engine had become normally aspirated.

The pilot advised ATC of his predicament and requested a lower altitude. During his descent, MP rose about 1 inch per 1,000 feet, seemingly confirming his “normally aspirated” diagnosis. The aircraft leveled off at the lower cruising altitude. All engine data still looked fine, so the pilot elected to continue to his planned destination, and landed without further incident.

After family and luggage were unloaded, the owner—one of my firm’s managed-maintenance clients—called us to describe what happened and seek advice. It was now late Sunday afternoon. Several of our most experienced A&P/IAs huddled and quickly agreed that the cause was almost certainly a major induction system leak caused by a hose clamp that had been loosened during the annual inspection and not properly tightened before the aircraft left the shop.

We’d seen this happen before on numerous occasions with this particular model aircraft, and we felt 95% sure that our diagnosis was correct. In fact, for a brief moment we were half-tempted to see how the owner felt about flying home normally aspirated and having the service center that performed the annual inspection find and fix its acts of omission.

However, we quickly disabused ourselves of that idea. Although we felt 95% confident in our diagnosis, there was still a 5% chance that it could be something else—something that could compromise safety of flight—something like an exhaust leak or flammable fluid leak that might result in an in-flight fire. That was clearly an unacceptable risk. So we advised the owner that while we thought the problem was likely a simple loose hose clamp, we wouldn’t feel comfortable about him making the return trip to Arkansas without first having a knowledgeable A&P inspect the engine compartment to make sure that nothing dangerous was going on.

There wasn’t a suitable service center at Kissimmee, but there were two nearby and the owner chose the closest one. First thing Monday morning, we contacted the shop, explained the situation, and asked if they would be willing to accommodate the aircraft on short notice and perform a firewall-forward inspection. They graciously agreed, and the owner flew the airplane the short hop to the service center.

By close-of-business Monday, the shop reported back to us that they’d gone over the engine compartment with a fine-tooth comb and couldn’t find anything obviously wrong. No loose induction clamps could be found, they told us, nor any exhaust leaks, oil leaks, or fuel leaks. While this certainly wasn’t what we wanted to hear—we were really convinced they’d find a loose clamp—it did convince us that the airplane was safe to fly home, and we told the owner so.

But that’s not what happened.

Airplane first?

Having failed to find the problem on Monday, the service center took it upon itself to call the Cirrus technical support hotline first thing Tuesday morning. They explained that they had a one-year-old airplane (still under warranty) with an unexplained loss of manifold pressure, and had been unable to find the cause. By the time we got word of this, the factory had already shipped a new turbo controller and wastegate assembly to the service center via next-day air, and the shop’s technicians were already at work removing the existing controller and wastegate.

We were floored by this turn of events, because we were certain that the symptoms experienced by the owner were not consistent with a controller or wastegate problem. We asked the shop why it had ordered the new controller and wastegate and started taking the airplane apart without first obtaining approval from us or the owner. The shop replied that since the airplane was under warranty and the owner would not have to pay for the parts or labor, they didn’t think owner approval was necessary.

Of course, now the owner would be stuck in Florida until at least the end of Wednesday. He was not exactly thrilled at this turn of events.

The new controller and wastegate showed up Wednesday morning, and the shop proceeded to install them. But when they pulled the airplane out of the maintenance hangar and performed a post-maintenance runup, they discovered a serious exhaust leak at the new wastegate. By now it was quitting time.

Thursday morning, the shop removed the new wastegate, installed a new gasket, reinstalled the wastegate, and performed another runup. This time, there was no exhaust leak. After lunch, they arranged for a local CFI to take the airplane up on a test flight. The CFI reported back that the turbocharging system wasn’t working, and the engine appeared to be running normally aspirated. Clearly, the replacement controller and wastegate had not changed the symptoms at all. (We told the shop on Tuesday—the moment we first heard that they’d ordered the controller and wastegate—that we were sure this would be the outcome.)

“And the evening and the morning were the fourth day.”

Friday morning, in desperation, the shop’s director of maintenance pulled his chief inspector off an annual inspection and asked him to look at our client’s airplane to see if he could find anything that the previous technician had missed. The chief inspector had a good set of eyes, and indeed he did wind up finding something: a loose induction clamp!

(Nope! Not gonna say it! Wouldn’t be prudent!)

The chief inspector tightened the clamp, cowled up the engine, and arranged for the CFI to make another test flight. This time, the CFI reported that everything was working perfectly. The shop called the owner and explained that they’d fixed his airplane and that there would be no charge, since everything they did would be covered under warranty (at a cost of many thousands of dollars to Cirrus). They probably expected the owner would be pleased to hear this news. He wasn’t.

“I’ve paid $1,000 in unplanned hotel bills for myself and my family while all this was going on,” the owner responded. “I’ve missed several days of work, including a really important meeting. WHO’S GOING TO PAY FOR THIS?” He was even more unhappy when he learned that the shop had test-flown the airplane twice without his permission—he’s one of those owners who doesn’t want anyone flying his airplane besides himself. (I can’t blame him, I’m the same way.)

This was an egregious case of “airplane first, owner second” thinking by the shop. They were so fixated on finding and fixing the airplane that they never gave any thought to the consequences of their actions on the owner. Their priorities were completely different from his, and that’s never a good thing. They took it upon themselves to make maintenance decisions without obtaining his prior approval, and that’s really bad.

In hindsight, what we should have done was to give the service center a limited troubleshooting budget on Monday morning: “Please spend no more than two hours of labor looking for this problem, then report back to us with your findings.” Had we done that, by Monday afternoon we would have been satisfied that nothing dangerous was going on in the engine compartment and we could have confidently recommended that the owner fly home normally aspirated and have the problem sorted out by his home service center on a timetable that was convenient for him. Lesson learned.

Case #2: Can’t get engine started

The very next week, we got a call from another client late Wednesday afternoon. He owns a virtually identical Cirrus SR22 Turbo except that it’s one year older—a 2009 model. This owner had flown to Tallahassee for the day, and was trying to get home in time for dinner. He couldn’t start the engine.

After a few minutes of playing “20 questions” with the owner to find out the symptoms, the diagnosis was obvious. The owner said that when he tried to start the engine, he could hear the starter contactor click and could hear the starter motor turning, but the prop would just twitch slightly but wouldn’t turn over. This is the classic symptom of a slipping Continental starter drive adapter—a fancy name for the clutch mechanism that couples the starter motor to the crankshaft when cranking the engine, and decouples it once the engine has started.

When we advised the owner of our diagnosis, he explained that there happened to be a factory authorized service center on the field at Tallahassee, and that he’d arrange to have the shop repair the problem.

“Noooo! You really don’t want to do that,” we told the owner, explaining that the service center would proceed to order a replacement starter drive adapter from Continental under warranty (which we knew were out of stock and backordered), and that his airplane would wind up stuck in Tallahassee for 7 to 10 days. The owner would either need to abandon his airplane and arrange alternate transportation home, or would wind up stuck in the local Motel 6 for at least a week.

We advised the owner to ask the Tallahassee FBO to hook up a 28-volt ground power unit to his airplane so he could attempt a GPU start. We explained that even though the starter drive adapter was slipping badly when attempting to start from the ship’s 24-volt battery, we knew from experience that it was usually possible to get a few more successful starts if the aircraft was hooked up to a 28-volt power source. We suggested that the owner attempt a 28-volt GPU start, and (if it was successful) fly the airplane home and deal with the starter drive adapter replacement back at home base.

The owner tried our suggestion and was able to get the engine started on the GPU. He phoned us on his cell phone to let us know he was about to launch for home. Our client made it home for a slightly late Wednesday dinner and was a very happy camper.

Meantime, we immediately contacted his home service center and arranged for them to put a replacement starter drive adapter on order and file the necessary warranty claim. The replacement SDA arrived on the Friday of the following week, and was installed on the engine the Monday after that.

To my way of thinking, this is exactly the right way to deal with breakdowns away from home. We diagnosed the problem, came up with a workaround allowing the owner to fly home without having to perform maintenance on the road, and arranged to have the aircraft repaired at the owner’s home shop where it could be done without undue inconvenience. It was a textbook case of “owner first, airplane second.”

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: