Tim bases his 1975 Cessna T210 in the Virgin Islands, and uses it mostly to fly throughout the Caribbean and sometimes to Florida. He first popped up on our radar screen when he called the SavvyBreakdown 24/7 hotline from his mobile phone.

“I just landed in Antigua,” Tim said, “and there’s something wrong with the landing gear system. The motor in the landing gear power pack did not stop after I put down the gear. I’m not sure if the gear will retract again, and there’s nobody here that knows anything about the 210 gear system.”

Within minutes, three of Savvy’s A&P/IAs were talking to Tim: SavvyBreakdown program manager Colleen Keller, technical director Jeff Iskierka, and on-call account manager Tony Barrell. They asked Tim a series of questions and learned that:

- The green gear-down light did not illuminate

- Pumping the gear down manually didn’t help

- Tim was able to verify visually that the gear looked to be down

- He landed gently and uneventfully

- After landing, the motor continued to run

- The green light remained off

- The main gear doors had not closed

- The hydraulic fluid level in the power pack was normal

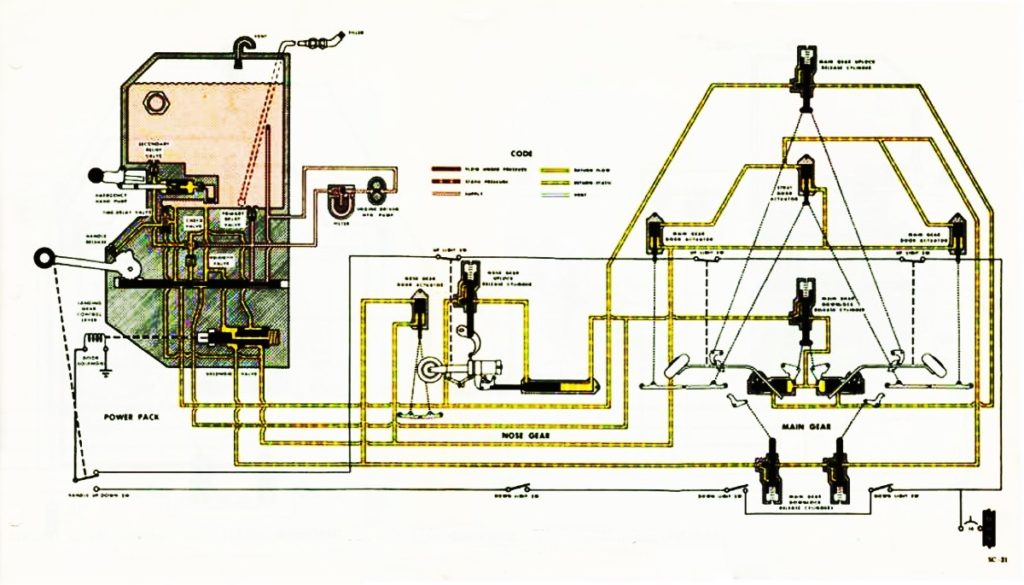

Now, the Cessna 210’s landing gear retraction system is a bit … how shall we put this? … baroque. It’s arguably the most complicated system on any retractable GA airplane ever built. It’s certainly one of the fussiest. And it’s notoriously difficult to troubleshoot.

Better Call Paul

Colleen, Jeff and Tony quickly concluded it was time to call in the big guns. Paul New A&P/IA is Savvy’s 210 specialist, and knows more about this particular make and model than anyone outside the Cessna factory. When Paul weighed in a couple of hours later, his encyclopedic knowledge was apparent.

“The same circuit that illuminates the green light (and the amber light in gear up mode) also energizes the door solenoid in the power pack,” Paul explained. “If the solenoid isn’t energized the hydraulic power isn’t transferred to the door actuators and the pressure switch can’t shut off the motor.”

“The problem here is a lack of completion of the gear down lock circuit,” Paul continued. “This circuit begins at the 5 amp gear circuit breaker and proceeds as follows:

- to the terminal block in the nosewheel well; then

- to the nose downlock microswitch; then back to the nose terminal block:, then

- to a terminal block in the belly just forward of the main gear; then

- to the left downlock microswitch; then back to the belly terminal block; then to the right main downlock microswitch; then

- back to the belly terminal block; and finally

- to the green indicator light.”

Troubleshoot Plan

Once Paul was confident that Tim understood how the circuit worked, he suggested the following steps to troubleshoot the issue:

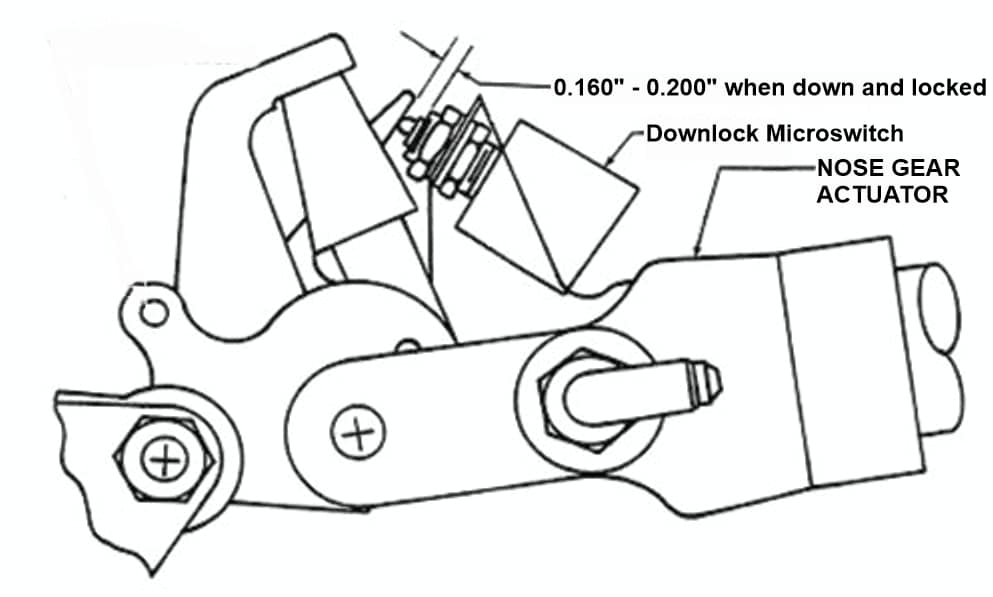

- First, check to see if all three downlock microswitches appear to be fully depressed. There should be between 0.160″ and 0.200″ of the switch’s plunger showing, not more.

- Next, gently tug on the wires at each switch to be sure the wire inside the insulation hasn’t broken (usually where it exits the switch body).

- If nothing physical is noted, then use a voltmeter to check at the terminal blocks to determine which switch is open or which wire is broken.

“Total troubleshooting time shouldn’t take more than about 20 or 30 minutes,” Paul told Tim, “including lifting a couple of floor access panels.”

“Paul, thank you for this information,” Tim said. “I will go back to the plane tomorrow and work through this. I’ve owned four Cessnas (and one Bonanza) previously and understand the airplane pretty well…except the landing gear system, which has always been a black box to me. I really appreciate the advice and support from Savvy, and I’ll give you a status report tomorrow.”

Success!

The next day, Tim reported: “Problem resolved! The nose downlock microswitch was not being depressed fully. Adjusted the switch travel and, voila!, everything started working normally.”

“After testing the gear doors on the ground numerous times, I test flew the plane and did six extensions and retractions. All worked normally. I’m no longer quarantined in Antigua. Thanks so much for the assistance with this!”

When you enroll your aircraft in our Breakdown Assistance —our unique “AAA for GA” breakdown assistance program—you have 24/7 access to Savvy Aviation’s amazing team of veteran general aviation maintenance experts—the most experienced, talented and trustworthy in the industry—who are dedicated to getting you back in the air as quickly and inexpensively as possible.

If you’re an aircraft owner, sooner or later you’re going to run into a mechanical issue away from home, and if you’re not enrolled in this program you’ll wish you were.

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: