Marc was the owner of a 1974 Cessna 414 who recently came to the conclusion that it was more aircraft than he really needed, with a voracious appetite for fuel and an overabundance of moving parts, many of which are fabricated from unobtanium or unaffordium. So, he wisely sold his cabin-class pressurized twin to a Caribbean charter outfit in favor of something a whole lot simpler and a whole lot newer: a 2006 Beechcraft Bonanza G36.

When he located this Bonanza being advertised online, it was being offered for sale by a major Beech/Cessna dealership in the midwestern U.S., about 1,000 miles from where Marc was situated in Florida. Although he is a highly experienced and maintenance-knowledgeable aircraft owner, Marc decided to engage Savvy to arrange and manage the prebuy of the G36 on his behalf. The task of doing that was assigned to Savvy’s account manager James Watson A&P/IA, a veteran mechanic and owner of an aircraft engine overhaul facility not far from Augusta, Georgia.

Agreement Between Buyer and Seller

The dealer’s sales executive agreed to cooperate with this, although he made it clear that he wasn’t exactly thrilled that Savvy would be involved. He told Marc: “Our complaint with Savvy is they like to critique and try to negotiate the terms of the purchase/sale agreement. They’re in the maintenance business and need to stay there and not get into the purchase order negotiating.”

Truth be told, the sales executive’s complaint about Savvy’s involvement was partly wrong but partially right.

When a prospective buyer engages Savvy to manage a prebuy for them, we never participate in negotiations with the seller—indeed, we never communicate with the seller or the selling broker—but we do our best to zealously protect the interests of our client, the buyer. Before we can start arranging a prebuy, the buyer and seller need to agree on a price and sign a “conditional purchase/sale agreement” that (among other things) gives the buyer the right to perform a prebuy examination of the seller’s aircraft, and sets forth what will happen after the examination is complete.

In our experience, selling dealers and brokers like to present prospective buyers with a conditional purchase/sale agreement that is heavily biased in favor of the seller and averse to the buyer’s best interests. Consequently, we always suggest to our clients that they model their agreement with the seller after the specimen agreement recommended by AOPA which we consider to be fair and equitable to both parties. Savvy has a slightly modified version of this agreement posted on its website that we provide to our prebuy clients as a guide.

Independence is Essential

The dealer’s sales executive also did his best to steer Marc’s prebuy to a shop that the dealer had used for prebuys many times before. This kind of thing is the kiss of death from Savvy’s perspective. We feel passionately that any prebuy we have anything to do with must be completely honest and independent. This means that it must be done by a shop or mechanic who has never set eyes on the aircraft before and who has absolutely no prior relationship with the seller or (if applicable) the seller’s broker. The fact that the selling dealer had worked regularly with this shop on prebuys in the past disqualified the shop from doing Marc’s prebuy as far as Savvy was concerned.

Fortunately, we were able to identify another shop within striking distance—Tri-State Aero in Evansville, Indiana—that we considered eminently qualified to do an independent prebuy on the G36 Bonanza. Tri-State’s Director of Maintenance (DOM) Jim Baird graciously offered to sandwich Marc’s prebuy into his busy shop schedule starting in about a week. We sent Jim our Bonanza prebuy checklist and asked them to provide a quote.

Like all our prebuy checklists, this one was divided into two distinct phases. Phase One focuses on the logbook review and the powerplant, while Phase Two covers the airframe, avionics, and ancillary systems. We ask the prebuy shop to complete the Phase One items and document its findings. Then, if no deal-killers are found, we ask the shop to proceed with Phase Two.

Jim posted a quote to complete both phases of the checklist at an estimated cost of $2,000. James told Marc he considered this to be fair. Marc agreed, and James asked Jim to schedule the prebuy.

One small logistical snag arose: When James asked Jim if Tri-State could arrange for a qualified pilot to test-fly the airplane—something that we feel is an important part of every prebuy, particularly for an advanced-technology cockpit like the G36—Jim said that he did not have availability of a pilot who could do this. After a few phone calls, it was agreed that the selling dealer’s ferry pilot would test-fly the plane from the left seat while Tri-State’s A&P occupied the right seat and checked out all the avionics and systems. Problem solved!

It’s Showtime!

“The G36 is in the hangar and we will be starting on it tomorrow,” posted Jim four days later—and two days ahead of schedule.

“That’s great!” replied James. “Were there any discrepancies noted during the ride-along test flight with the ferry pilot?”

“The flying weather was not good,” Jim said, “so we were not able to get to fly it. I guess we’ll have to reschedule that after we complete the examination.”

“This plane suffered a gear-up landing,” Marc told James, “and I would like you to ask the shop to give special attention to those repairs. I want to be assured all was done on a first-class basis.” James passed this request on to Jim.

The next day, shortly before quitting time, Jim posted “Done with Phase One” and provided a list of what had been found so far:

- Compressions: 70-64-63-63-58-68

- Spark plugs need to be cleaned and gapped

- Inboard gear doors are loose, looks like just hardware

- Only one oxygen mask aboard

- Pilot seat armrest loose

- Gear motor brushes are due (500-hour item)

- Fuel selector valve inspection due (10-year item)

- Fuel boost pump overhaul due (10-year item)

- Wing attachment bolt inspection due (10-year item)

So far, so good. The last four “due” items are things that Savvy would typically recommend declining anyway (since we believe in doing maintenance on-condition, not on a fixed timetable). The compression readings were all well within Continental’s go/no-go criteria, not to mention that we generally pay more attention to borescope findings than to compression readings. A borescope inspection of all cylinders is part of every Savvy Phase One prebuy checklist.

“Could you send over some borescope images, particularly of that #5 exhaust valve and the cylinder barrel?” James requested. “Where was the air leaking on that cylinder?” “The leakage appeared to be past the rings,” said Jim. “I’ll send you some borescope images tomorrow.”

Leakage past the rings is not particularly worrisome, especially if oil consumption is reasonable. (Leakage past the exhaust valve is of far greater concern.)

“Please proceed with Phase Two of the checklist,” James instructed Jim. At this point, he was confident that there were no Phase One show-stoppers. “Please look at the wing-attach bolts for signs of corrosion. Also, please make sure you pull up the floorboards to inspect the areas where the gear-up landing repairs were made. Let us know what you find.”

Uh oh, trouble!

“The wing bolts look okay,” Jim reported the next day, “BUT we have a problem with the repair under the floorboards.”

“What’s the issue?” asked James.

“Bent ribs,” replied Jim. “I will get you photos shortly.”

“Thanks Jim, standing by for pictures,” said James.

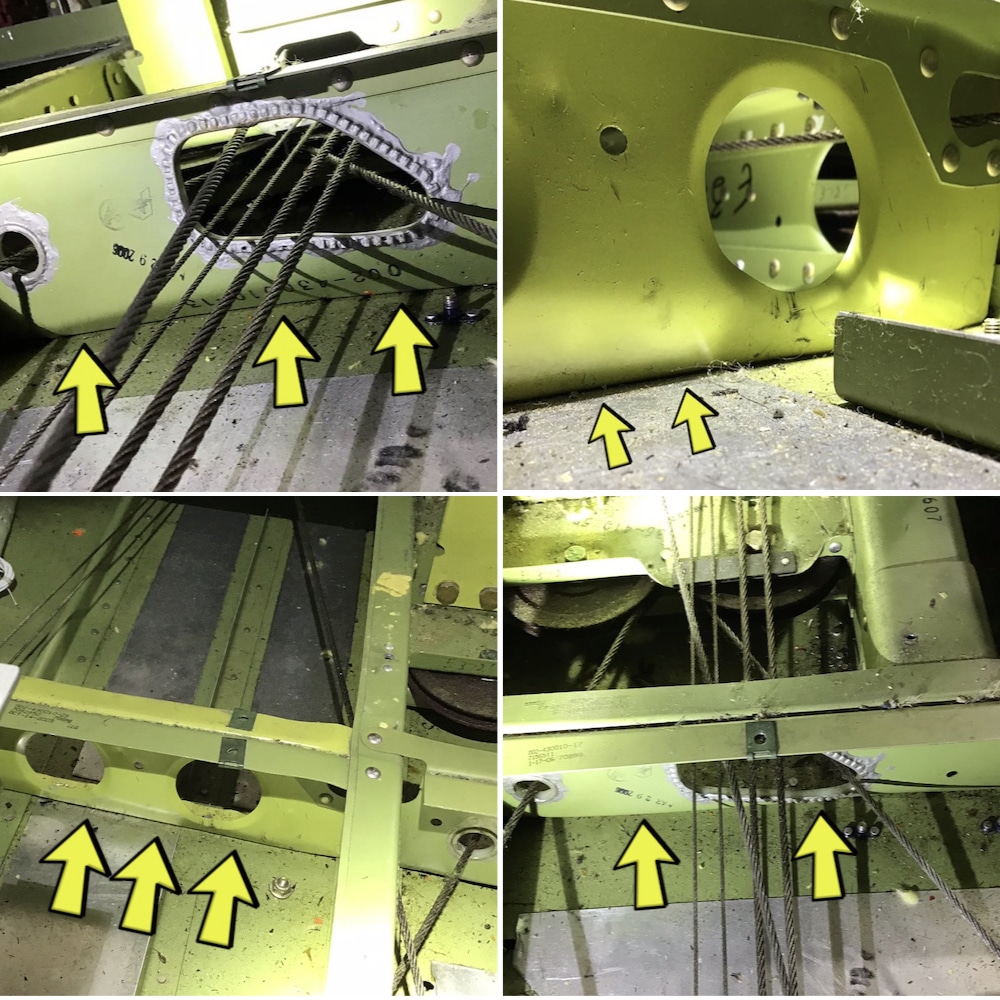

Within the hour, Jim posted the following images:

Oh wow, that is nasty!” James told Marc. “Definitely not a proper repair. It’s not even clear that the shop that did the repair saw this damage, otherwise it surely would have been addressed. I don’t have a good feeling about this.”

Jim confirmed James’ suspicion that there was no evidence of any repairs in this area. He suggested that the two ribs need to be replaced. But aside from this, he felt it was a solid airplane.

Marc reported this finding to the dealer’s sales executive, who offered to have the bent ribs straightened and a stiffener installed. That didn’t sound to Marc like a kosher repair. James asked for Jim’s opinion about this approach.

“Perhaps a stiffener could be installed,” Jim said, “but we would need to get in touch with Textron Engineering and see how they feel about such a repair. I’ll email them the photos and see what they have to say. If Textron approves, we could do the repair here.”

“Sounds like a plan,” said James. “Let us know what Textron thinks about how to repair this damage.”

Two days later, Jim received a response from Textron and passed it on to James and Marc. It was titled “Textron Aviation – Repair Definition Quote” and in a nutshell it said:

- Textron Engineering considers the rib damage to be repairable.

- The charge for Textron to develop and provide an approved repair document would be $4,300, and it would take four weeks to develop it.

- The charge to do it on a priority basis and get it done a week sooner would be $6,700.

- These quoted charges are strictly for the development of the repair document including any necessary engineering analysis, and do NOT cover any of the parts or labor cost of actually doing the repair.

Wow!

Jim had his crew put the plane back together. The selling dealer had their ferry pilot pick the plane and fly it back to the dealer. The selling dealer agreed to replace the damaged ribs after concluding that doing so would probably be less expensive (and would certainly be quicker) than paying Textron Engineering to come up with a way to repair the damaged ribs.

A couple of weeks later, Marc posted some happy news:

“Repairs completed. Deal is done. Delivery is taken!”

Marc’s experience was a textbook example of the importance of having a truly independent prebuy examination performed by a really competent shop whose allegiance is strictly to the buyer. We’ll leave it to your imagination what might have happened if instead the prebuy had been done by the shop that the seller wanted to use? Not to mention what expletive Marc might have uttered if the damage had been found during the G36’s first annual inspection on his watch.

Perhaps it’s less than surprising that the executive at the selling dealer was not exactly overjoyed to learn that Marc had engaged Savvy to assist with the prebuy. We’ll gladly take that as a badge of honor. If accused of being a bit overzealous in looking after the best interests of our aircraft-buyer clients, we unapologetically plead guilty as charged.

If you’re in the market to buy an airplane, wouldn’t you feel a little more confident with Savvy looking out for your best interests?

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: