Yikes! It’s far worse than I expected, and it must be stopped.

By Mike Busch

I must be losing my touch.

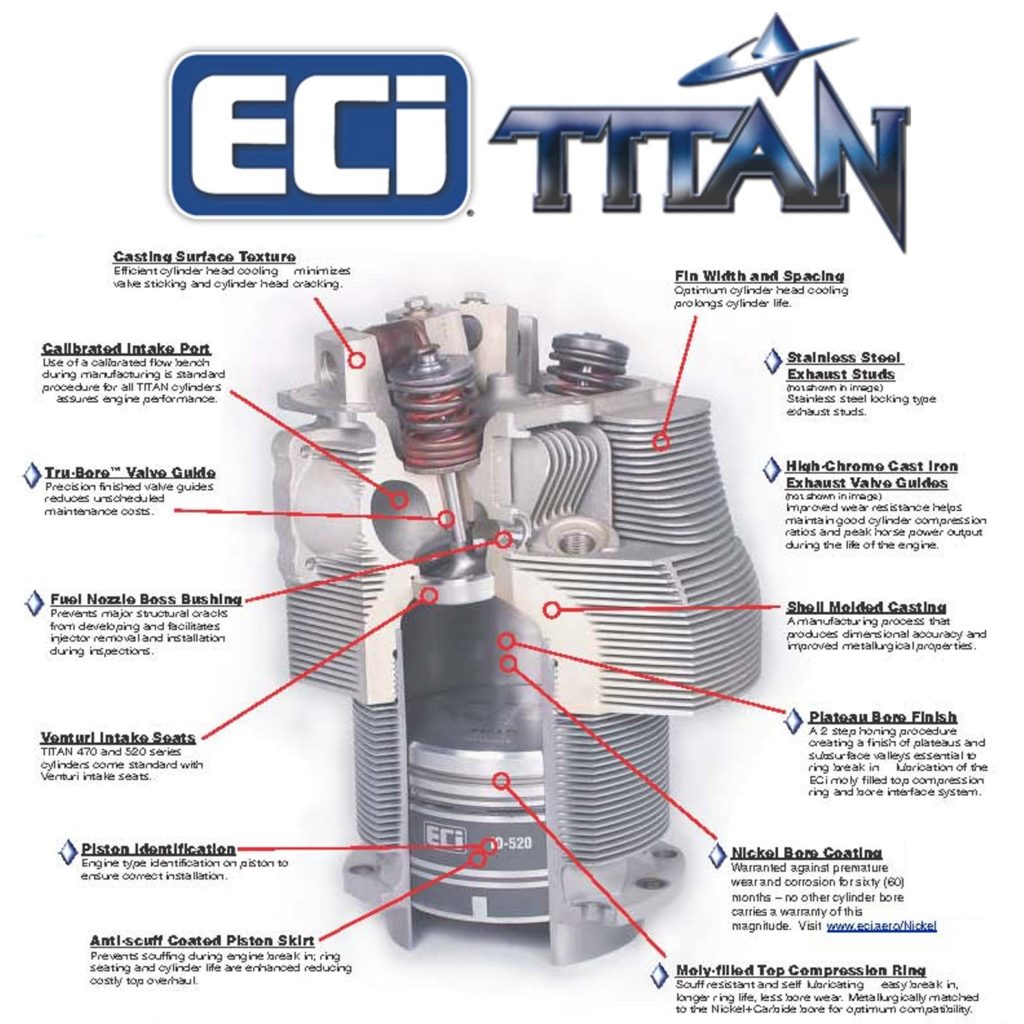

When I last wrote about this subject 9 months ago—in the February 2013 issue of EAA Sport Aviation—I reported that in 2009 the FAA effectively legislated out of existence Superior Millennium-brand investment-cast cylinders (that many considered to be the best-built cylinders for Continental engines available at the time), and that the FAA was working busily to do the same thing to ECi TITAN-brand cylinders (that many consider to be the best-built cylinders for Continental engines available today). In that article, I said that the Superior AD 2009-16-03 mandated the life-limiting of 8,000 investment-cast Millenniums at an FAA-estimated cost to owners of $12.4 million, and I estimated that the forthcoming AD against ECi TITANs would life-limit 20,000 cylinders at a cost of $30 million.

Wow, did I ever blow those estimates!

The FAA issued its Notice of Proposed Rulemaking (NPRM) for the ECi TITAN AD on August 12, 2013, and when I read it I was absolutely floored. It turns out that the proposed AD would actually euthanize 36,000 cylinders on 6,000 Continental 520- and 550-series engines at an FAA-estimated cost to owners of $82.6 million, making it one of the most costly General Aviation ADs in history.

How could I have underestimated the FAA’s action so badly?

Well, I guess it’s because I assumed that the FAA would take the same sort of action against ECi cylinders and they did against Superior cylinders in 2009. That’s precisely what the NTSB asked them to do in its February 2012 Safety Recommendation A-12-7. Specifically, I expected the FAA to call for repetitive inspections of the cylinders every 50 or 100 hours, and retirement when the cylinders reached Continental’s recommended engine TBO (typically 1,600 to 2,000 hours).

But that’s NOT what the FAA did.

Massive euthanasia

Instead, inexplicably, the NPRM calls for all 36,000 affected ECi TITAN cylinders to be removed from service when they reach 1,000 hours, or removed from service immediately if they’ve already passed the 1,000-hour mark. In addition—and I find this particularly mind-blowing—the NPRM calls for about half of those cylinders to be removed from service immediately if they have less than 500 hours on them.

I am not making this up! (I wish I were.)

It is not unusual for the FAA to issue an AD as a result of a Safety Recommendation by the NTSB. But it’s nearly unprecedented for the FAA to issue an AD that is vastly more severe than what the NTSB asked for. It’s almost always the other way around.

Much ado about nothing

One might well expect that for the FAA decided to use its regulatory might to condemn 36,000 ECi TITAN cylinders on 6,000 engines at an estimated cost to aircraft owners of $82.6 million, the agency would have a convincing argument for doing so, right? If you review the NPRM (http://www.regulations.gov/#!documentDetail;D=FAA-2012-0002-0027), here’s the totality of the FAA’s justification:

This proposed AD was prompted by failure reports of multiple cylinder head-to-barrel separations and cracked and leaking aluminum cylinder heads. We are proposing this AD to prevent cylinder head cracks, engine failure, and loss of the airplane. We are proposing this AD because we evaluated all the relevant information and determined the unsafe condition described previously is likely to exist or develop in other products of the same type design.

What the FAA conveniently fails to mention in its NPRM is that nobody has been able to find a single instance where a head crack or head-to-barrel separation of an ECi TITAN cylinder has caused an accident or an injury. There have been ZERO instances of “engine failure” and ZERO instances of “loss of the airplane.” And there probably never will be.

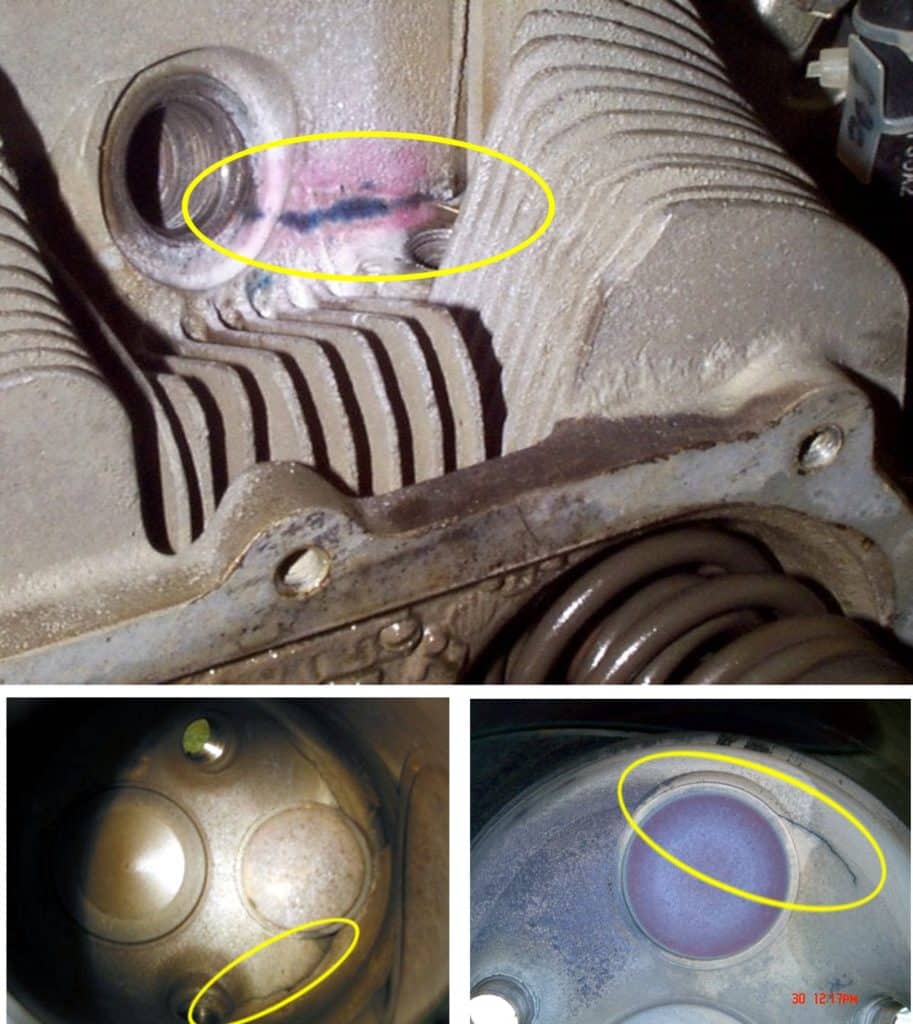

Let’s put this business of head cracks in perspective. We’ve been living with “cracked and leaking aluminum cylinder heads” for as long as we’ve had aluminum cylinder heads. By the time a cylinder approaches TBO, it’s a good bet that it has one or more head cracks. Over the years, I’ve had to retire three of the 12 Continental factory cylinders on my own Cessna T310R because of cracks at the top spark plug boss. Mac McClellan has had a similar experience with his Baron. One of my clients recently decided to perform a top overhaul on his 1900-hour IO-550 engine (against my advice) and the cylinder shop found that all six of his Continental factory cylinders had head cracks.

A recent review by a large well-known cylinder shop of 700 cylinders sent in for overhaul found that 75% of the cylinders had head cracks. About 40% of those cracks originated at one of the spark plug bosses, 20% of them were in the exhaust ports, 14% in the exhaust valve seat bosses, 11% in the fuel nozzle bosses, and the remaining 15% in various other places. None of these cracks were detected until the cylinders were removed. None of them caused any sort of performance problem or presented any sort of safety issue. The cylinders worked just fine despite the cracks.

In the decades I’ve been paying attention to such things, I’ve never heard of an airplane falling out of the sky because of a cylinder head crack. Roughly 99.9% of these head cracks are completely benign. One might even say they’re normal.

Head-to-barrel separations

The only sort of head cracks worth worrying about are cracks at the cylinder’s head-to-barrel junction. Cracks in this location—if they go undetected long enough—can progress to the point of a complete head-to-barrel separation.

Cracks in the head-to-barrel junction area are exceedingly rare, representing only a small fraction of a percent of head cracks. Actual head separations are even rarer. According to the FAA’s own Service Difficulty Report database, there were only 29 reports of head-to-barrel separations of ECi cylinders (out of a population of more than 30,000), and of those only 21 could be verified. That’s a failure rate of less than 0.1%.

Now, just because head separations occur less than 0.1% time doesn’t mean we can ignore them. After all, we wouldn’t accept an 0.1% failure rate of wing spars or propeller blades. But failures of wing spars and propeller blades have the potential to make airplanes fall out of the sky and to hurt or kill people. Head separations don’t.

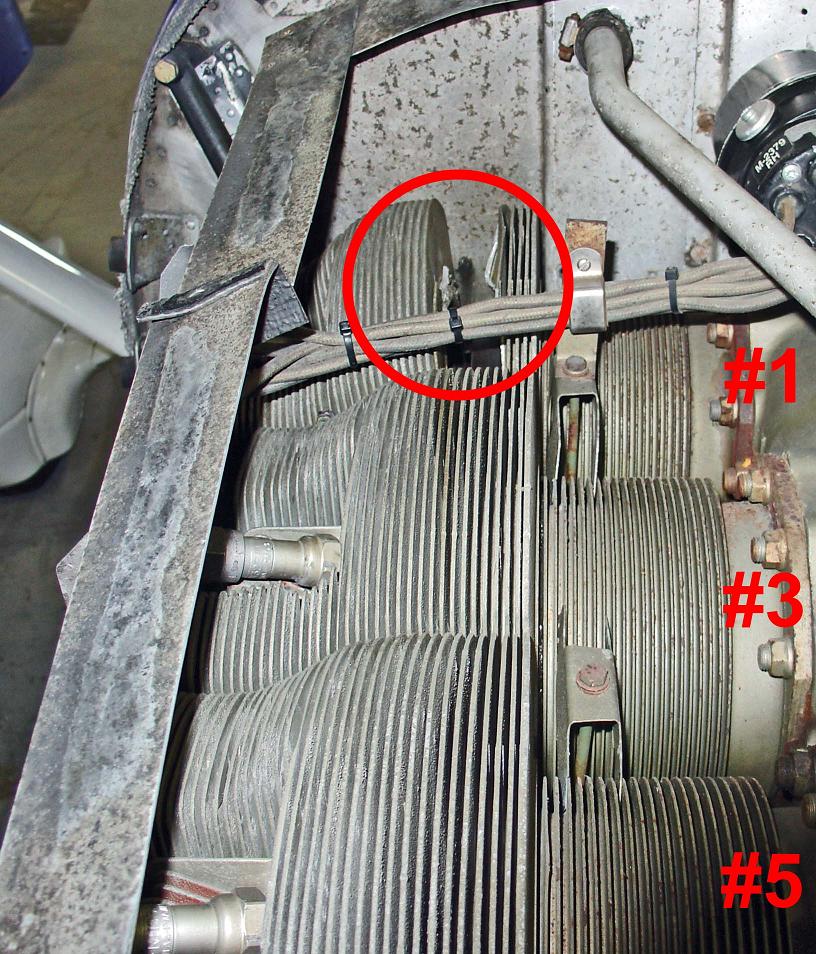

Consider what happens when a cylinder on a Continental 520/550 engine suffers a head separation: The cylinder goes to zero compression and shuts down, leaving the engine capable of producing about 80% power. The head separates from the barrel by one inch or less, held in place by the exhaust and induction manifolds. The separation stops the cylinder’s valves from opening so there’s no uncontained exhaust and no induction leak. The barrel remains firmly attached to the crankcase, and the piston happily continues to reciprocate in the zero-compression environment, with only a tiny loss of engine oil.

The engine continues to run on five cylinders. It’s undeniably rough, but not rough enough to hurt anything. In fact, FAR Part 33 requires that every certificated piston aircraft engine be demonstrated to run with one inoperative cylinder at all RPMs from idle to red-line without harmful vibration. In short, you probably wouldn’t want to fly a long cross-country in that condition, but there’s never a problem flying to a safe landing at the nearest suitable airport. The problem is even less significant if it occurs in a twin, and the lion’s share of reported ECi TITAN head separations occurred in Cessna 340s and 414s.

What prompted the NTSB recommendation?

This whole mess began with the October 2010 fatal crash of a Cessna 402C in Nassau, Bahamas that killed all nine people aboard the airplane. The aircraft was Bahamian-registered as C6-NLH. The accident was investigated by the Air Accident Investigation and Prevention Unit (AAIPU), which is the Bahamian counterpart of the NTSB. You can view the AAIPU’s final report on this accident at http://www.aaipu-bcaa.com/FinalReports/C6-NLH.pdf and it make interesting reading.

Briefly what happened is that the Cessna 402C departed from Nassau, Bahamas with 9 people and a whole lot of baggage aboard. The aircraft was at between 500 and 700 pounds over gross. The 12,000-hour PIC took exceptionally long to perform his pre-takeoff runup checks, and some witnesses indicated there was some backfiring during the runup. The PIC then made an intersection takeoff, and upon application of takeoff power the left engine immediately started emitting white smoke. The tower radioed the aircraft that they were trailing smoke from the left engine. The pilot stated his intention to return to the airport and land on runway 27. The aircraft commenced a left turn at an estimated altitude of 150 to 200 feet. The landing gear was re-extended and the left turn tightened until the bank angle was 90 degrees, whereupon the aircraft cartwheeled into a lake.

Post-accident investigation of the left engine revealed that the #2 cylinder had suffered a head-to-barrel separation. The engine was clearly making partial power on five cylinders. It appears that the pilot shut down the RIGHT engine by mistake; both mag switches and the alternator switch for the RIGHT engine were found in the OFF position, while the mag switches and alternator switch for the LEFT engine were all in the ON position. Neither propeller was feathered and the landing gear was extended. Inexplicably, both fuel selector levers were found to be in the OFF position.

The left engine’s #2 cylinder was indeed an ECi cylinder. However—and this is crucial—it was NOT a new-manufacture TITAN cylinder, but rather an overhauled continued-time cylinder (sold by ECi under the FREEDOM brand name) in which the barrel and head had been de-mated, the barrel plated with nickel, and then the head re-mated. As is typical of continued-time overhauled cylinders, the total time-in-service of the cylinder head was not tracked or recorded, but it was undoubtedly way past Continental’s recommended TBO. The cylinder was originally manufactured in 2006, overhauled by ECi in 2008, then repaired at least once after that (the exhaust valve, guide and seat were replaced with Superior parts).

From the standpoint of head-to-barrel junction separation, a new-manufacture ECi TITAN cylinder (which is primarily what would be affected by the NPRM) is a totally different animal than an overhauled ECi FREEDOM continued-time cylinder whose time-in-service is completely indeterminate and whose head-to-barrel junction has been “messed with” during the overhaul.

AAIPU made 15 specific safety recommendations as a result of this crash, but none of them were directed at the engine or cylinders. AAIPU clearly considered this accident to be caused by pilot error—indeed, the pilot did just about everything wrong—and not by equipment failure. The investigators concluded that the airplane could have climbed, even over gross, with the right engine producing 100% power and the left engine producing roughly 80% power. The pilot turned a minor problem into a catastrophe by attempting a steep-bank turnback maneuver from an altitude of 200’ AGL, lowering the landing gear before landing was assured, and apparently shutting down the best engine (and possibly both engines) but failing to feather the propeller(s).

It strikes me as absurd that such an accident, albeit tragic, could have triggered this horrendous proposed AD against new-manufacture ECi Titan cylinders. But that seems to be exactly what happened.

Why this AD is a terrible idea

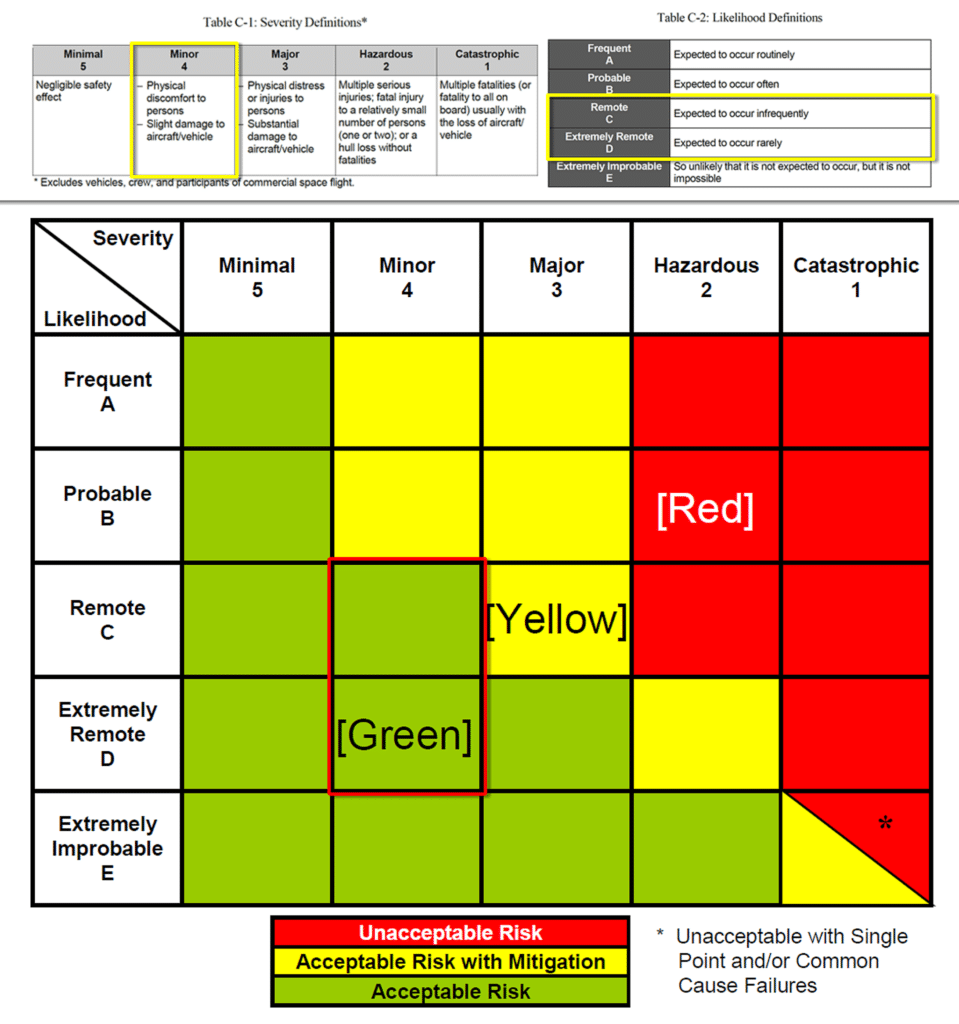

The FAA’s own published Safety Risk Management Policy (Order 8040.4A) provides a specific algorithm and matrix for assessing whether a particular safety risk is acceptable or unacceptable, based on both the likelihood and severity of the risk involved. The data shows clearly that the likelihood of head-to-barrel separations is “remote” (less than .001) and the severity is either “minimal” or “minor” (because the engine doesn’t quit and nobody gets hurt). If you plug this into the FAA’s own risk matrix, you’ll find that head separations represent an “acceptable risk” for which no mitigation is necessary.

In my opinion—and the opinion of other maintenance experts whose opinions I respect—the safety risk arising out of the 6,000 top overhauls that would be compelled by the proposed AD is vastly greater than the safety risk arising out of doing nothing. In recent years, I have served as an expert witness in a half-dozen lawsuits involving aircraft that fell out of the sky because of improperly performed top overhauls. Several of these accidents were fatal. I feel so strongly about this that I always advise my managed-maintenance clients against allowing a top overhaul to be performed anywhere but at an engine shop (although sometimes they don’t follow my advice). There is absolutely no doubt in my mind that the proposed AD would create far more safety risk that it would cure.

Help stop this!

I urge every EAA member—whether or not you have ECi cylinders—to submit comments to docket FAA-2012-0002 urging the FAA to withdraw this ill-conceived proposed AD. If the FAA is permitted to do this to ECi TITAN cylinders (which have the lowest head-to-barrel separation rate in the industry), what’s to stop them from doing it to Continental and Lycoming factory cylinders?

You can submit your docket comments online at http://www.regulations.gov/#!submitComment;D=FAA-2012-0002-0027. I’ve already submitted mine. The original deadline for submission is October 11, 2013, although AOPA, EAA, CPA and several other organizations have asked the FAA for a 120-day extension to the comment period which I expect to be granted.

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: