Dick loved his 1966 Mooney M20E. It was a magic carpet that let him and his wife travel all over the East Coast from their home base in North Carolina. Although the airplane was more than 50 years old, Dick had had it painted with a fancy new paint scheme, retrofitted it with fancy glass-panel avionics, and had updated its Lycoming IO-360-A1A engine with a PowerFlow exhaust, a Surefly electronic ignition system, and a JPI EDM-930 digital engine monitor configured with sensors for just about everything that could be instrumented.

Three years ago after the plane suffered a prop strike, Dick had the engine torn down and installed a new Hartzell “Scimitar” propeller, new Hartzell prop governor, and a new McFarlane vernier prop control cable. But when the work was done and Dick was able to fly his Mooney again, things just didn’t seem right.

RPM Fluctuations

The first thing Dick noticed was that when the airplane was in stable cruise, RPM seemed to wander more than he was used to. This in spite of the brand new prop, governor, and control cable. Or perhaps because of them?

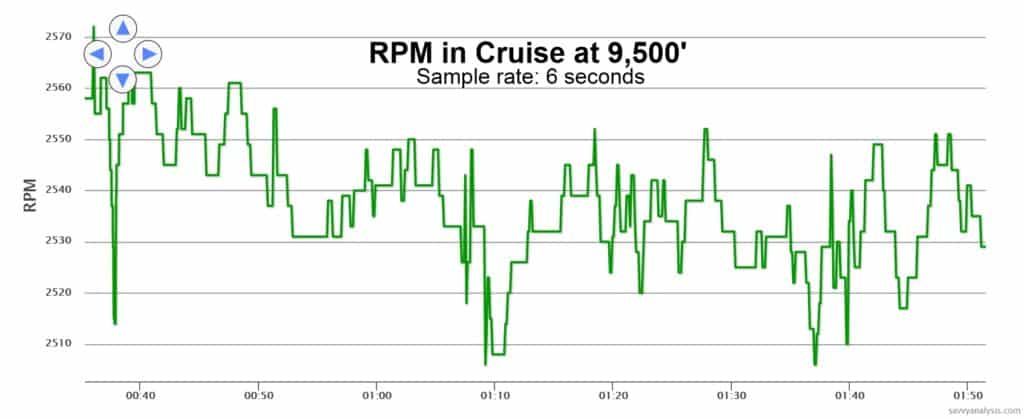

Dick uploaded his JPI EDM-930 data to the SavvyAnalysis platform and asked Savvy to take a look at it. Dick’s request was assigned to Savvy’s resident Mooney expert Paul Kortopates, who examined the data from one of Dick’s long cross-country flights. When Paul isolated the RPM data for a portion of the flight lasting nearly an hour during which the plane was cruising at an altitude of 9,500 feet without any significant changes in manifold pressure or airspeed, here’s what he saw:

Paul agreed that the 50 RPM fluctuations in stable cruise were abnormal. He looked at oil pressure to see whether there was some correlation between the RPM fluctuations and oil pressure fluctuations, and concluded that there wasn’t. After conferring with Dick to make sure there was no slop in the new prop control cable (Dick confirmed that there wasn’t), Paul concluded that the new prop governor was the most likely suspect.

Dick put the Mooney back in the shop and had the prop governor removed and sent back to the prop shop for bench-checking. The governor was still under warranty, but the prop shop warned that there would be a $150 charge if they found nothing wrong with the governor. A week later, the prop shop returned the prop governor with a report saying that they had bench-checked it and found nothing wrong, but they didn’t invoice Dick for the $150. Interestingly enough, when Dick had the governor reinstalled and flew the airplane, the RPM fluctuations were dramatically improved.

“I guess the act of inspecting the governor must’ve fixed it,” Dick told Paul. “Funny how that works.”

More Fluctuations: Fuel Pressure and Flow

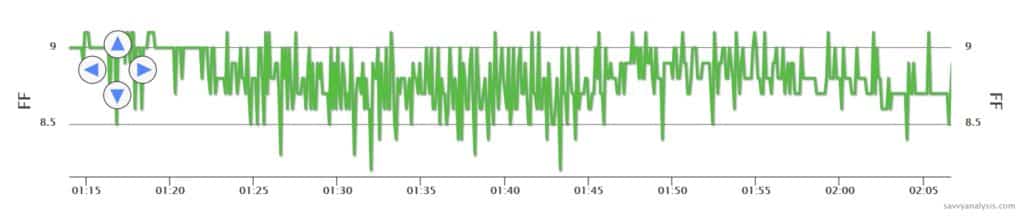

Resolving the problem with unstable RPM uncovered another issue: “When I lean the engine in cruise, the fuel flow indication is fluctuating up and down,” Dick reported, “and this can be clearly seen when the engine monitor data is graphed.”

“What might be going on?” asked Dick. “Partial fuel nozzle blockage? Transducer issue?”

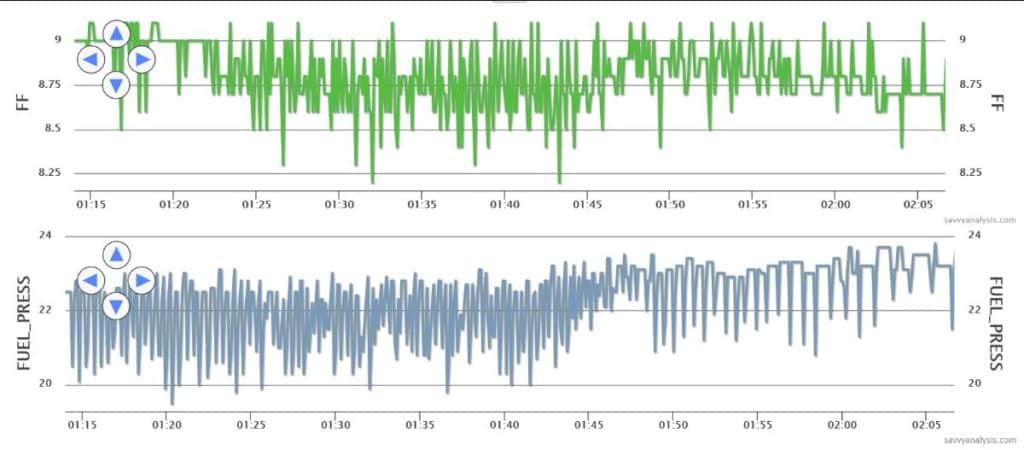

Paul studied the data. The fluctuating fuel flow indication was certainly abnormal, yet there was no corresponding anomaly in the EGTs that would suggest a clogged fuel nozzle or fuel servo problem. However, further investigation revealed unusual fluctuations in fuel pressure that seemed to correlate with the fuel flow fluctuations:

This convinced Paul that this was something more than a simple transducer problem, and that something real was going on that was affecting both fuel pressure and fuel flow indications. But what?

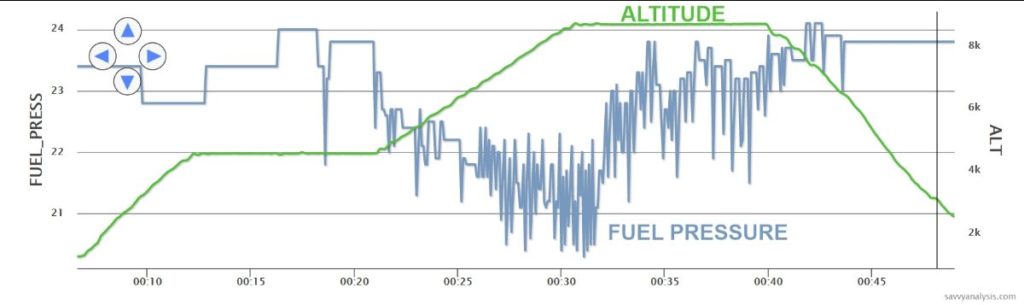

This seemed like a real head-scratcher until Paul tried plotting fuel pressure against aircraft altitude and noticed something interesting:

The fuel pressure fluctuations seemed to increase with altitude, and seemed to be worse during high-power climb than low-power descent. A light bulb went off.

“This is starting to look like it might be some sort of vapor lock problem,” Paul told Dick. “Is it possible that you have a fuel line that is exposed to a lot of heat? Also, have you tried using the electric boost pump in cruise for vapor suppression to see if it reduces the fluctuations?”

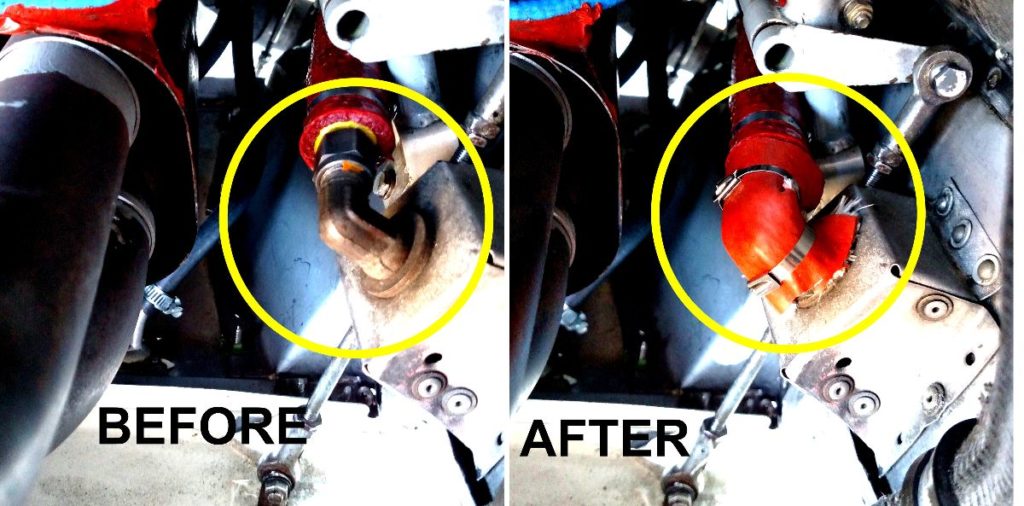

Dick inspected the Mooney’s engine compartment and noticed that there was an exposed fuel elbow fitting that was in fairly close proximity to the #4 exhaust header. The fuel line connected to that elbow fitting was protected by firesleeve, but the elbow fitting was unprotected. Dick added an additional length of firesleeve to protect the elbow fitting:

A subsequent test flight showed that the fuel flow fluctuations were significantly reduced, although not completely eliminated. Progress!

Two weeks later…

“I got to fly from North Carolina to Massachusetts yesterday at 11,000 feet so I had a chance to further test our hypothesis regarding vapor lock being the cause of the fluctuations in fuel pressure and fuel flow,” Dick posted to Paul. “I uploaded the flight data to my Savvy account so you could look at it. About two hours into the flight, you can see where I turned on the electric boost pump, which raised the fuel pressure to 25.1 PSI and eliminated the downward spikes on the fuel pressure graph. A few minutes later, I turned the boost pump off and the spikes returned though their amplitude seemed to be less.”

“I looked at your recent flight and I certainly see what you mean,” replied Paul. “The boost pump cleared the fuel pressure spikes right up, which really supports the notion that they’re vapor-lock-induced fluctuations. It also helped smooth out the fuel flow fluctuations as well, proving that they were secondary to the fuel pressure issue.”

Paul went on to point out to Dick that the POHs for later-model Mooneys give a lot more guidance about using the electric boost pump to reduce vapor lock than the older-model POHs do. For example, the POH for the Mooney M20TN Acclaim says to use low boost in climbs above 12,000 feet and in cruise at 18,000 feet and above. The Cirrus SR22TN POH also recommends using the boost pump for high-altitude cruise and while climbing above 6,000 feet. By way of contrast, older-model POHs like the one for Dick’s 1966 M20E refer to using the boost pump only for takeoff, landing, switching tanks, and emergencies such as engine-driven pump failure.

Paul suggested to Dick that there would be nothing wrong with using the electric pump in climb or cruise whenever fuel pressure fluctuations are noticed.

As a SavvyAnalysis client, Dick was fortunate to have access to the expertise of Paul Kortopates, who in addition to being one Savvy’s senior engine data analysts is also an A&P/IA, CFIA, CFII, AGI, IGI, FAASTeam Lead Representative, MAPA Pilot Proficiency Program instructor, Mooney owner, and one of the most knowledgeable Mooney experts in the country. Paul is one of nearly 30 members of Savvy’s superb technical team whose combined encyclopedic knowledge and experience spans everything from E-ABs and LSAs to cabin class twins, turboprops, bizjets and just about everything in between.

No matter what you fly, wouldn’t you benefit from having a veteran expert like Paul helping you analyze and troubleshoot your aircraft’s powerplant?

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: