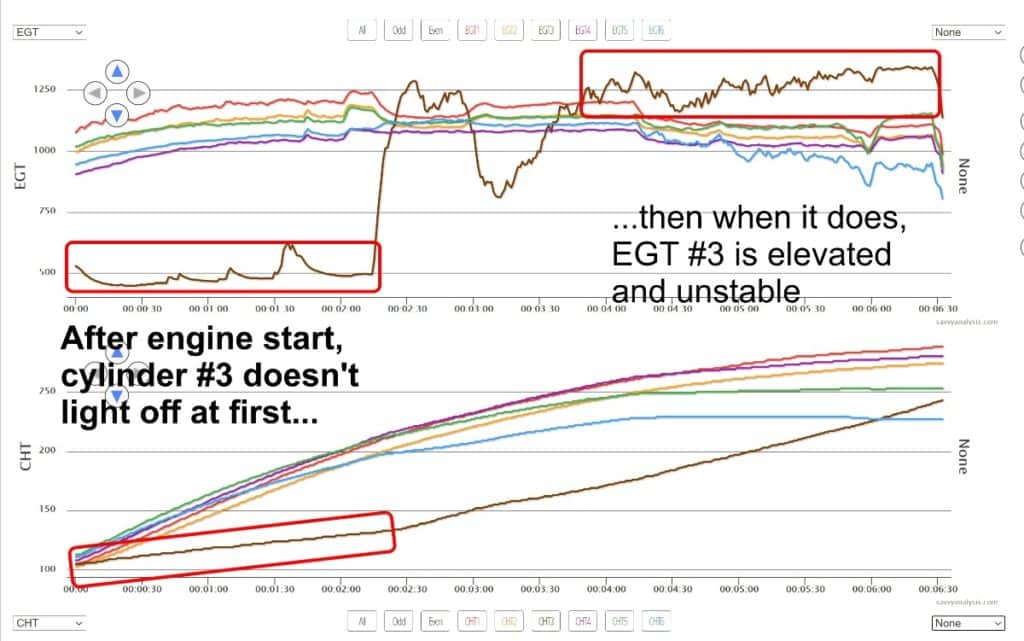

“Requesting analysis to understand the possible root causes on this engine start,” Willy posted at the beginning of his newly-created SavvyAnalysis ticket. “I hadn’t run my 1966 Beechcraft Bonanza V35’s engine for two weeks, and when I started it I noticed that EGT #3 was extremely low (less than 500°F) causing the ΔT alarm to go off. I’m convinced that the EGT #3 reading is accurate, since the CHT #3 was also very low.”

“I throttled up to higher RPM and the EGT #3 shot up to 1200°F,” Willy continued. “When I throttled back to idle, EGT #3 once again set off the ΔT alarm but this time because it was too high (1300°F). Nothing like this has ever happened before in the three years I’ve owned this airplane. Do you have any idea what might have caused these funky EGT #3 readings? Sticking exhaust valve? Clogged fuel nozzle? Bad spark plug? (The spark plugs have only about 40 hours since they were last cleaned and gapped.)”

Savvy’s chief analyst Joe Godfrey assigned this ticket to himself. “This is a tricky one,” Joe admitted. “I think it’s probably an ignition issue, because I’m noticing that when cylinder #3 comes online at 02:15 its EGT isn’t steady. It looks to me as if the ignition is weak and not reliably igniting the air-fuel mixture on every successive combustion event.”

“It might be helpful if you’d do a thorough engine runup and mag check and then dump the data to see what that reveals. However, if you’d rather skip that step and just remove and inspect the spark plugs, I would not disagree with your decision. By the way, you might also want to check the plugs in cylinder #6 while you’re at it, because I’m seeing what could be a weak ignition issue in that cylinder as well.”

A few days later, Willy posted…

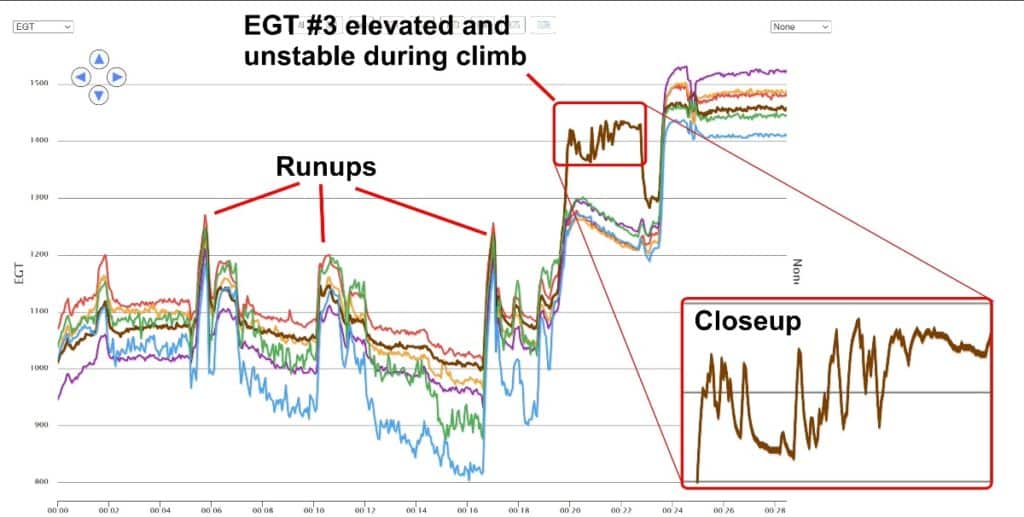

“Following your recommendation, I did three runups with mag checks on July 21st.”

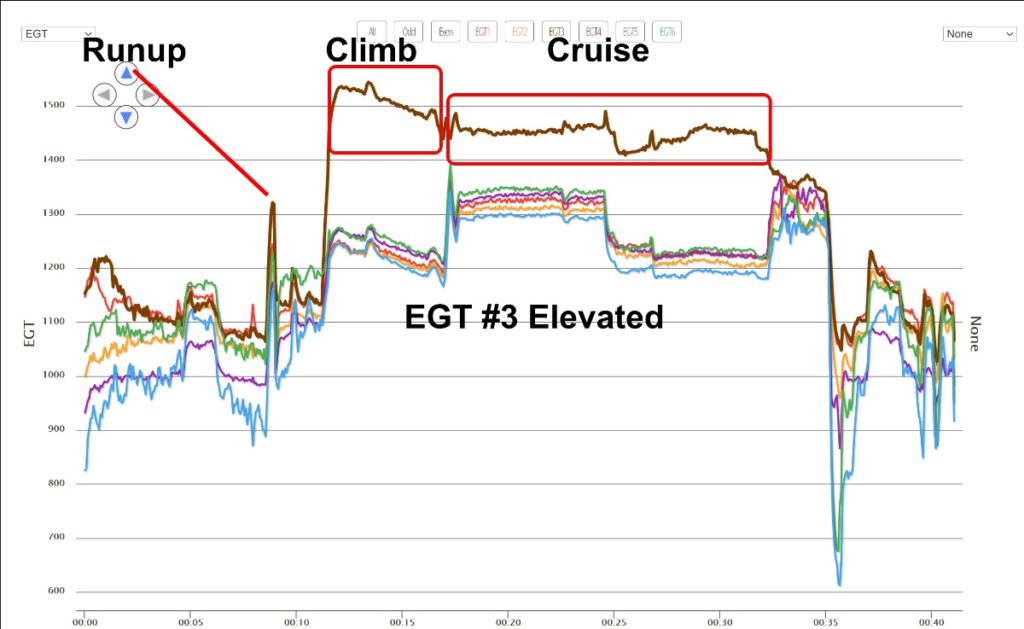

“The first two runups and mag checks all seemed normal. I then took off but during the climb EGT #3 was 200°F higher than the other cylinders.”

“After landing, I did another runup and mag check, and this time EGT #3 was about 100°F higher than the other cylinders. I took off again, and this time EGT #3 was 300°F higher than the others during the climb and set off the ΔT alarm.”

“Some other facts that might be helpful: The magnetos are Bendix S-1200s with 400 hours since overhaul. The ignition harness was replaced 71 hours ago. The fuel nozzles were cleaned at the annual just 9 hours ago. Do you think I should have the magnetos overhauled or IRAN’d?”

“It still looks like a spark issue to me because when CHT #3 drops at 17 mins into the flight, EGT #3 stays high,” explained Joe. “If it were a fuel related issue, I’d expect both CHT and EGT to move in the same direction. I suggest checking the spark plugs in cylinder #3 before attacking the magnetos with tools. If it were a mag issue, I’d expect all six cylinders to be affected—and I’m not seeing that. Besides, it’s always best to do the simple stuff first.”

“Thanks for your advice, Joe,” replied Willy. “I’m traveling for the next week, but when I get home I’ll pull the spark plugs and let you know what I find.”

Willy’s Confirmation

“Joe, I wanted to follow up and let you know that I pulled the spark plugs from cylinder #3 per your recommendation.”

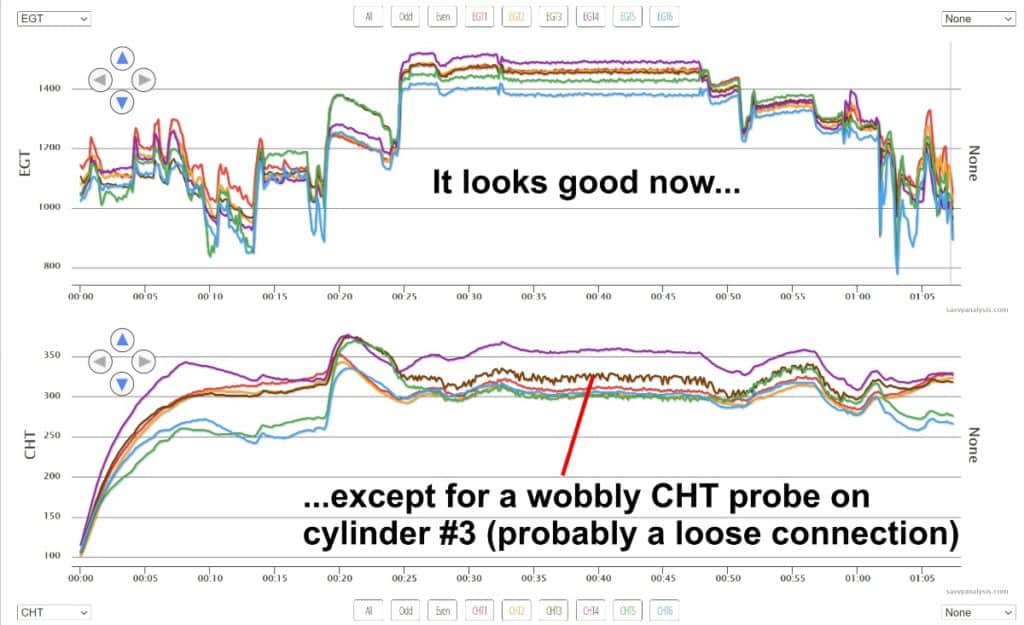

“The bottom plug had very high resistance, and both top and bottom plugs exhibited weak and irregular sparks in the spark plug test box. So I replaced both plugs on cylinder #3, and flew the airplane on August 3rd. If you look at the data for that flight, you’ll see that the EGT #3 now looks perfectly normal.”

“That’s great news,” said Joe. “I’ll close this ticket, but please holler if you need anything else. And oh, by the way, your #3 CHT looks a bit noisy, so I’d suggest checking the probe’s electrical connections to the harness.”

Willy is clearly a sharp aircraft owner who understands the value of engine monitor data analysis as a diagnostic tool. He provided Joe everything he needed to quickly diagnose the issue in rifle-shot diagnosis. As a result, WIlly was able to detect his ignition problem early (before it turned into a safety-of-flight issue) and resolve it very inexpensively (by replacing two marginal spark plugs). Joe’s expert guidance saved Willy the cost and downtime associated with preemptively sending his magnetos in for overhaul or IRAN—roughly $1,500 and 10 days, respectively.

Learn more about SavvyAnalysis.

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: