There’s metal in your oil filter. Now what?

“I’ve been a happy aircraft owner until this morning,” Frank wrote me. “My aircraft is in the shop for its annual inspection, and the mechanic just called to say that they found magnetic chips in the oil filter, and the big-bore Continental engine would have to be taken out and completely disassembled. Do you have any advice how to proceed?”

Ouch!

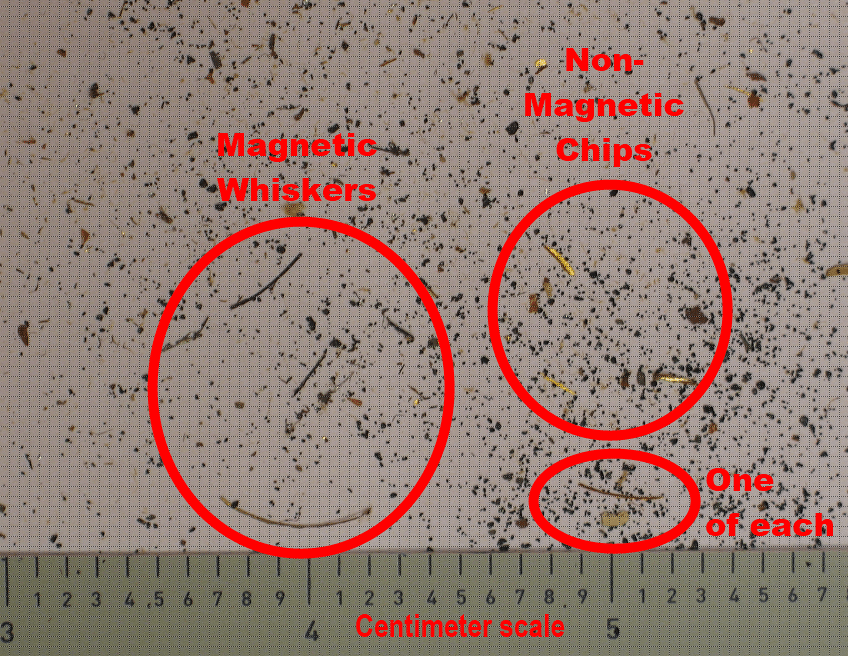

I asked Frank to email me a photo of the filter contents, and he did. (See Figure 1.) I saw a few curved magnetic whiskers and a few small bronze-colored chips. Certainly enough to get my attention and pique my curiosity about their source, but hardly anywhere close to warranting a $20,000 engine teardown.

I asked Frank a few follow-up questions and learned that his engine’s starter drive adapter had recently started slipping and had been replaced. The small quantity of metal in the filter struck me as being entirely consistent with what one would expect to see from a failing starter drive adapter. So I advised Frank to have his mechanic change the oil and oil filter, then go fly the airplane for 10 hours or so, and then have the new oil filter cut open and inspected. I added that tearing down the engine because of such a small quantity of easily explainable metal in the oil filter struck me as being a grotesque overreaction on the part of his mechanic.

A few days later, Frank reported back that despite his best efforts of persuasion, the mechanic refused to budge. He refused to sign off the annual as airworthy unless Frank agreed to have the engine torn down and inspected. Frank was upset, but felt the mechanic had him over a barrel—a very expensive barrel indeed.

Taking it upstairs

As luck would have it, the next week I would be attending a conference with a senior executive of Continental Motors, someone I’d known for years. So I asked Frank to package up the contents of his oil filter in a clear zip-lock plastic bag and send it to me. I stashed the baggie in my briefcase and brought it to the conference.

At a break in the conference, I presented the little bag of filter contents to my friend from Continental and asked him, “would you recommend tearing down an engine if you found this in the oil filter?” He shook his head, and then gave me one of those looks that I took to mean “is this a trick question?”

I told him about Frank’s predicament, explained that his mechanic was holding Frank’s airplane hostage, discussed Frank’s recent starter adapter failure and replacement, and asked whether he agreed that the metal most likely came from the now-replaced starter adapter. He nodded. I asked whether he thought a reasonable course of action would be to change the oil and filter, fly another 10 hours, and then check the filter again. He agreed that was a good plan.

Then I asked my friend from Continental Motors the $20,000 question: “Would you be willing to put that in writing, and send it to Frank’s mechanic?”

After a brief pause my friend replied, “Tell you what… Let me take this back to Mobile and have it checked out in our metallurgy lab.”

A few days later, my friend emailed me to let me know that they’d examined Frank’s filter contents and clearly established that the metal was indeed from the starter adapter, just as I suspected. At my request, he then sent an email to Frank’s mechanic recommending that the aircraft be flown for 10 hours and the filter cut open an inspected.

After receiving guidance directly from the engine manufacturer, Frank’s mechanic relented and agreed to sign off the annual. Some weeks later, Frank brought the airplane back to the shop after flying it for about 10 hours. The mechanic cut open the filter and found it to be free of any metal.

Frank is happy. So is his mechanic. Case closed.

What’s a mechanic to do?

Frank’s experience is not unusual. My firm manages the maintenance of 400 piston airplanes, and hardly a week goes by that I don’t encounter a metal-in-the-filter situation. More times than not, the mechanic who finds the metal in the filter overreacts and starts doing exploratory surgery on the engine—pulling cylinders, alternators, starter adapters and other appliances—or tells the owner that the engine has to be torn down. Whenever I become aware of such a situation, I try my best to prevent it from happening.

Some mechanics lack the experience or the confidence to determine whether or not a little metal in the oil filter constitutes a safety-of-flight issue. Many are scared to death of the possible consequences if they approve an engine for return to service and then something goes wrong. Frankly, it’s hard to blame them, given the insanely litigious nature of aviation maintenance nowadays.

The solution is for the engine manufacturers to provide detailed written guidance to mechanics that gives them specific courses of action to take when metal is found in the oil filter. And therein lies the problem.

Continental provides no written guidance on this subject that I’ve been able to find. This leaves the full decision-making burden squarely on the shoulders of each inspecting mechanic. And for reasons I mentioned earlier, mechanics often make decisions that are ultra-cautious…and ultra-expensive for the aircraft owner.

Lycoming, on the other hand, has long provided rather extensive written guidance for mechanics on this subject. Unfortunately, Lycoming’s guidance on oil filter inspection appears in such an obscure location—Lycoming Service Instruction 1492 with the unlikely title “Piston Pin Wear Inspection”—that most mechanics don’t even know that it exists. That’s a pity, because it’s incredibly useful guidance, and following it would prevent countless unnecessary and inappropriate engine teardowns, cylinder removals, and other costly and invasive procedures.

What Lycoming Says

Lycoming has revised its guidance in SI 1492 several times. For many years, the guidance was quite simple and easy to follow:

- If the filter contains less than 1/8 teaspoon of metal particles, flakes or whiskers, change the oil and filter, fly the engine for 25 hours, then cut open and inspect the new filter.

- If the filter contains between 1/8 and ¼ teaspoon of metal particles, flakes or whiskers, change the oil and filter, fly the engine for 10 hours, then cut open and inspect the new filter.

- If the filter contains any large pieces of metal the size of a broken lead pencil point or larger (1/16” in diameter), or contains more than ¼ teaspoon of metal particles, flakes or whiskers, ground the engine until the source of the metal is determined.

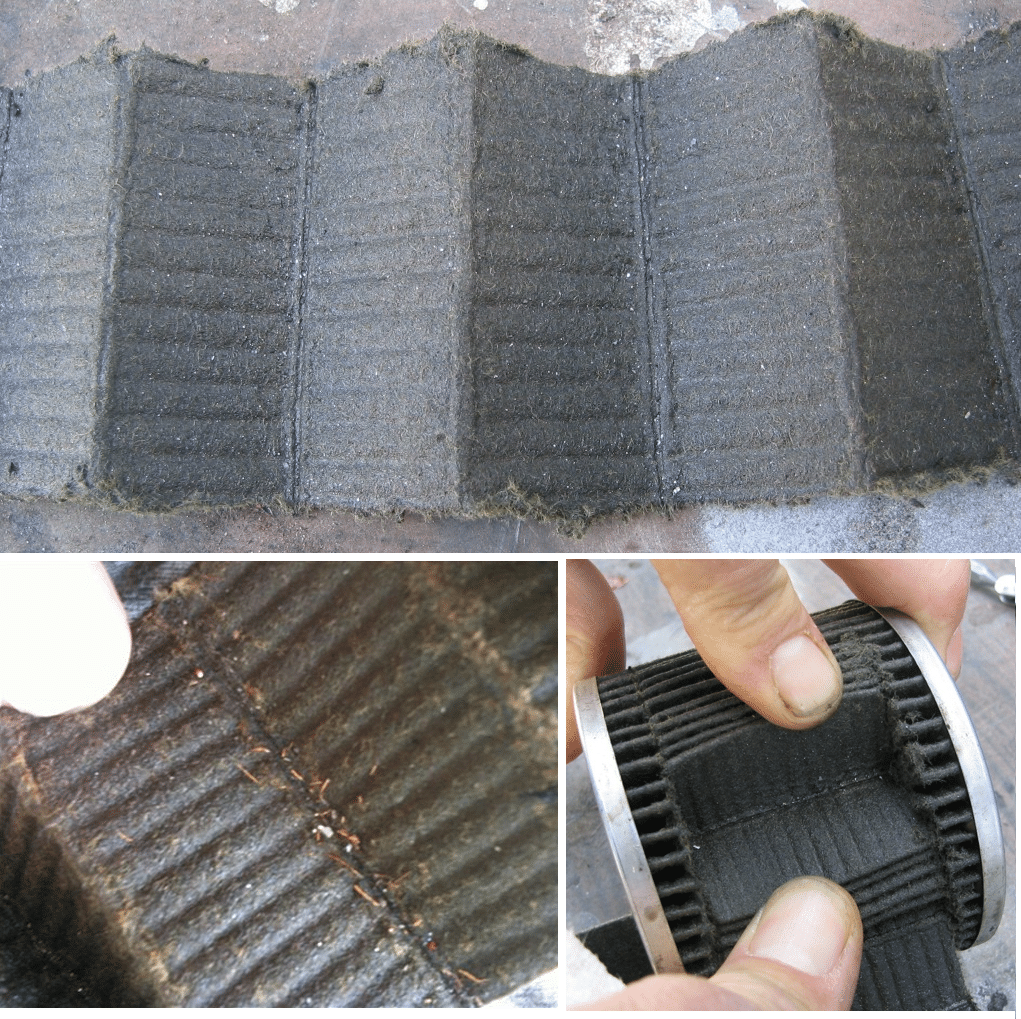

By the way, ¼ teaspoon of metal is a LOT of metal! (See Figure 3.)

The bottom line of Lycoming’s guidance is that the engine should not be grounded unless the filter contains a LOT of metal. If it contains only a small or moderate amount of metal and no big chunks, the appropriate action is to change the oil and filter, fly the airplane for a little while (10 to 25 hours), then cut open the filter to see if the issue is getting better or worse.

In recent years, Lycoming has amended its guidance on oil filter inspection, and made it a bit more complicated. The latest revision—Service Instruction 1492D issued in March 2009—offers the following guidance (which I’ve simplified slightly):

- If the filter contains 1 to 9 small pieces of metal (1/16” diameter or less), change the oil and filter, then inspect the filter at the next regularly scheduled oil change.

- If the filter contains 10 to 20 small pieces of metal (1/16” diameter or less), change the oil and filter, then inspect the filter after 25 hours.

- If the filter contains 20 to 40 small pieces of metal (1/16” diameter or less), change the oil and filter, then inspect the filter after 10 hours.

- If the filter contains a larger quantity of small pieces of metal (1/16” diameter or less)—such as 45-60—change the oil and filter, run the engine on the ground for 20-30 minutes, then inspect the filter and suction screen. If they are clean, fly the aircraft for 1-2 hours and then inspect again. If still clean, inspect again after 10 hours.

- If the filter or suction screen contain large pieces of metal the size of a broken lead pencil point or larger (1/16” diameter) totaling ¼ teaspoon or more, ground the engine until the source of the metal can be determined.

- If metal is found in the amount of ½ teaspoon or more, remove the engine and perform a teardown inspection.

What about Continentals?

Because Continental does not provide any similar guidance for mechanics, my usual approach when metal is found in the oil filter of a Continental engine is to use the Lycoming guidance. I think this is a reasonable thing to do because Lycoming and Continental engines are very similar in design and metallurgy, and it seems to me that having some guidance is always better than having no guidance.

In my maintenance management practice (where more than 90% of my clients fly Continental-powered airplanes), I’ve been fairly successful in persuading mechanics to accept Lycoming’s guidance. But as you might imagine, sometimes it’s a tough sell.

Consequently, I’ve recently asked Continental Motors to consider issuing a new service bulletin about oil filter inspection that would provide specific cookbook-style guidance to mechanics comparable to what Lycoming has done in its SI 1492D. As I’m writing this article, I’m told that Continental has scheduled an Engineering Department meeting to discuss the possibility of issuing such a service bulletin. Film at eleven.

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: