All airplanes occasionally get sick. Even mine.

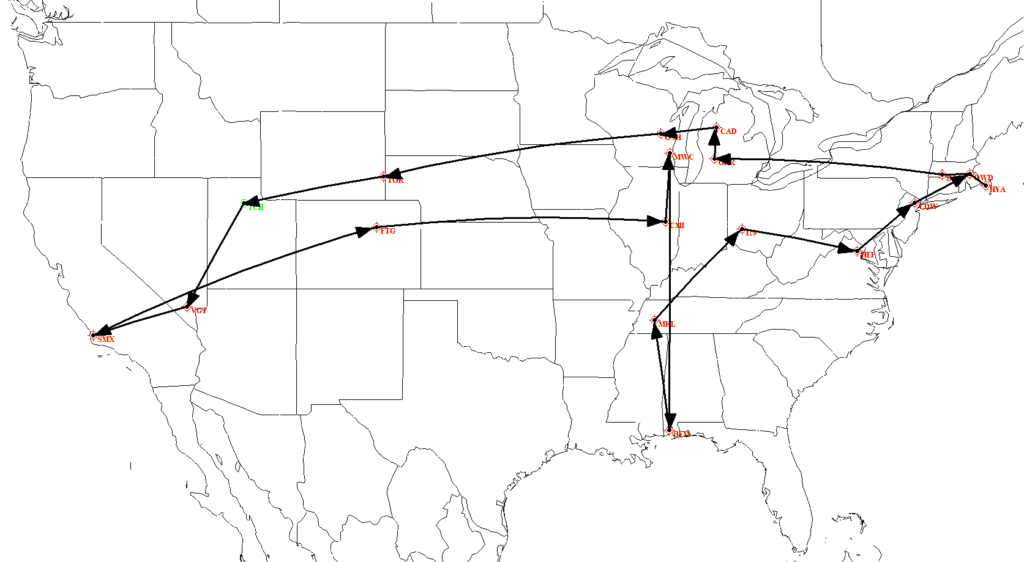

Every year, I take my airplane on a big summer trip around the U.S., speaking at various aviation events and culminating with a week at EAA AirVenture. This year’s trip was 50 days long—June 17th to August 5th—and covered 6,500 nautical miles, put 40 hours on the Hobbs, and consumed $7,500 of 100LL.

I’ve owned my 1979 Cessna T310R for 25 years, and it’s been an amazingly reliable machine. However, this year’s trip involved an unprecedented number of airplane problems, almost as if the airplane had saved up five years’ worth of glitches and decided to dump them on me all at once. This made the trip more…ah…interesting.

My first destination was Champaign, Illinois for three days of simulator training. The forecast called for thunderstorms over the Front Range starting at about 2 pm Mountain Time, so I figured if I launched from California by 8 am Pacific, I’d be able to make it over the high terrain and land at Denver’s Front Range Airport by 1 pm, beating the bad weather by an hour. I’d RON in Denver and launch for Illinois first thing the next morning.

The plan worked perfectly, although an hour after I landed a tornado touched down right in the middle of DIA, shutting it down for 30 minutes and causing numerous airline flights to divert. Fortunately, the tornado missed Front Range and spared the airplanes parked there (including mine).

Engine trouble

Next morning, I started engines and picked up my clearance to Champaign. I was cleared for takeoff on Runway 17, taxied into position and slowly advanced the throttles full forward. Something wasn’t right.

The right engine came up to 32” of manifold pressure, but my left engine showed 24” and wouldn’t go higher. The engine monitor and fuel flow gauge confirmed the asymmetry. I rejected the takeoff, exited the runway, and told tower that I had a mechanical.

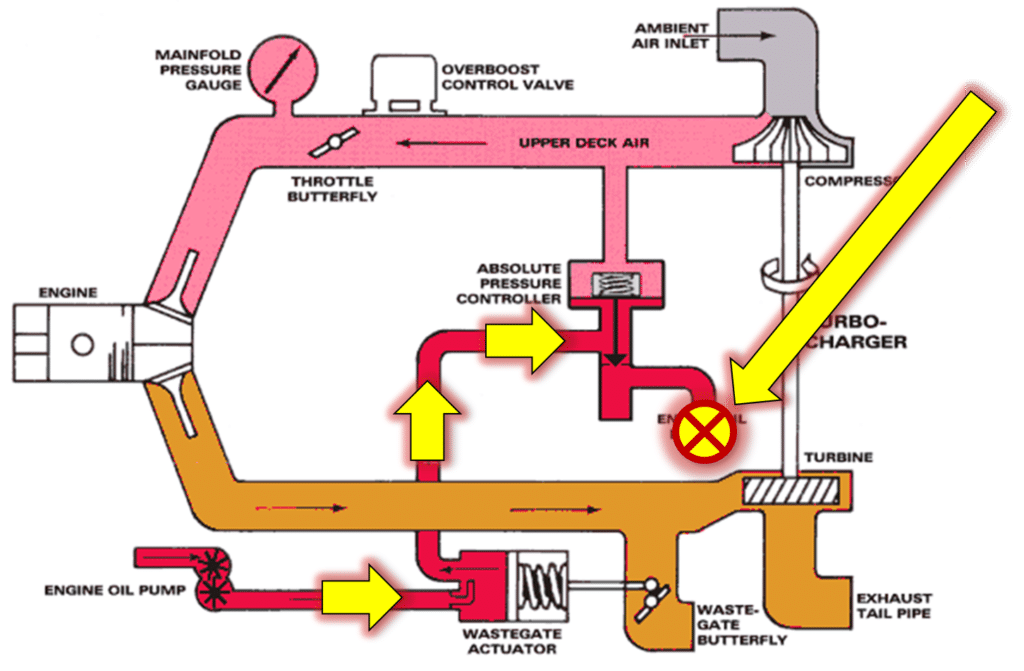

Fiddling with engine controls while watching engine instruments convinced me that the left engine was acting normally aspirated instead of turbocharged. The 24” of manifold pressure is just about what I’d expect without turbocharging on takeoff from a field elevation of 5,500’.

Dammit!

Tower directed me to a small, maintenance shop called Executive Air East. I introduced myself to the two owner-mechanics, explained my predicament, and they said they’d be happy to help. We uncowled the left engine and gave it a thorough visual inspection. Nothing looked wrong, no obvious exhaust, induction, fuel or oil leaks. I removed the induction air filter and reached in to spin the turbocharger by hand; it felt healthy.

By the process of elimination, I concluded that the turbocharger must not be spinning up because wastegate wasn’t closing to force exhaust gas through the turbine. I could think of only two possible causes: Either the wastegate was stuck open or the turbocontroller wasn’t commanding the wastegate to close. But which?

I came up with a plan: We would disconnect and cap off the oil return hose from the turbocontroller to the engine. Doing that would take the controller out of the system and ensure that the wastegate actuator was getting all the oil pressure needed to close the wastegate.

We capped off the oil return hose, cowled up the engine, and I performed a quick full-power runup of the left engine. It now made 32” of manifold pressure as advertised. This meant that the wastegate was now closing, the rest of the turbosystem was working, and the problem had to be in the controller.

I considered taking the controller apart, but remembered an old trick that had worked for me last time I had a controller problem 20 years ago, and figured it was worth a try. We removed both oil lines from the controller and then shot a few blasts of compressed air into the controller’s oil outlet fitting in an attempt to dislodge any foreign material that might be stuck in its poppet valve. Sure enough, the air blast blew some chunks of carbon into a waiting rag.

Fingers crossed, we reconnected both oil lines to the controller, cowled up the engine again, and I did another full-power runup. The engine made 32” of manifold pressure. Yessss!!!!!

I thanked the mechanics, settled up their bill for one hour of labor, filed another flight plan from my iPhone, launched from Runway 17 uneventfully about two hours past my original P-time, and landed in Champaign mid-afternoon.

I survived the three days of sim training and my instructors’ numerous attempts to kill me with every sort of failure they could come up with. It was time for me to move on to my next stop, Milwaukee, Wisconsin, to speak at the annual meeting of the Flying Physicians Association. The flight from Champaign to Milwaukee’s Timmerman Airport took only about an hour and was uneventful.

Autopilot trouble

Three days later, it was time for me to fly to Mobile, Alabama, where the Cirrus Owners and Pilots Association were having their tenth annual Cirrus Migration and had invited me to speak. The leg from Milwaukee to Mobile would be just shy of four hours’ flying time.

After takeoff, I tried to engage the autopilot but it wouldn’t! How lovely… This was going to be a long four hours if I had to hand-fly the whole way.

I checked the circuit breaker panel and found the autopilot computer breaker popped. I reset it. It didn’t pop again, but the autopilot still showed no signs of life.

The popped breaker was an important clue that something must have fried in the 400B autopilot computer. Obviously I wasn’t going to be able to fix this myself, so upon landing I phoned my favorite autopilot guru—Bob Weber at Mayday Avionics in Grand Rapids, Michigan—and described the symptoms. Bob agreed that it was almost certainly a power supply problem in the 400B computer. I pulled the computer out of the back of the airplane, boxed it up, and overnighted it to Bob.

Cirrus Migration concluded, and I hand-flew to Jackson, Tennessee to spend the Fourth of July week with my friends Paul and Helen New, who own and operate Tennessee Aircraft Services. A week later, it was time for me to move on.

My next destination was Washington, DC where I had meetings scheduled at AOPA Headquarters and would be getting together with friends and colleagues in the DC area. Paul asked me to give him a lift to Columbus, Ohio where he needed to pick up a customer’s airplane and fly it back to Jackson for its annual. After dropping Paul off in Columbus, I flew to Manassas Regional Airport. By the time I landed, I’d done more hand-flying in one week than in the previous ten years combined, a character-building experience.

Big Left Turn Syndrome

I spent four days in the DC area. Meanwhile, Bob Weber was able to get my autopilot computer repaired, bench-tested, and overnighted back to me at my hotel in Tysons Corner. I drove out to Manassas, reinstalled the computer, and ran a few ground checks to confirm the autopilot was working.

Next destination was Boston, where I’d be visiting with my sisters and preparing the eleven technical presentations that I was scheduled to give at AirVenture. I decided to stop in Caldwell, New Jersey to have lunch with Steve Vander Valk, another colleague who co-owns Paragon Aircraft Services, a top-notch Cessna and Cirrus service center in the greater New York area.

I launched out of Manassas and engaged the autopilot. ATC gave me a series of vectors, which the autopilot flew flawlessly, following the heading bug of my Sandel electronic HSI. As I reached various ATC-assigned altitudes, the autopilot’s altitude-hold was working like a champ. So far, so good.

ATC said “resume own navigation.” I engaged the NAV mode of the autopilot to track my GPS course…and something bizarre happened. The airplane turned left, and continued turning left with no sign of rolling out of the turn! I watched in disbelief, then after about 90 degrees of turn, I manually disengaged the NAV mode. The autopilot dutifully turned right and flew the heading bug. I tried NAV mode several more times, and it did exactly the same thing each time: Big Left Turn. After lunch with Steve, I launched for Norwood, Massachusetts. I tried NAV mode again. Same result: Big Left Turn. @#$%^*!

Over lunch, Steve mentioned to me that there was excellent 400B autopilot shop at Hyannis, Massachusetts: Griffin Avionics. So after I landed at Norwood and checked into my hotel, I phoned Griffin and asked if I could fly the airplane to Hyannis and have them take a look at the 400B NAV-mode problem. They put me on their shop schedule for the following Thursday morning.

On the appointed day, I launched from Norwood at 0730 to arrive at Hyannis by 0800. I engaged the autopilot early in the 20-minute flight, then leveled off at 5,000’ with altitude-hold and tried engaging NAV-mode, fully expecting another Big Left Turn. But the 400B had another surprise up its sleeve: This time, NAV-mode worked perfectly! I even shot a fully-coupled ILS approach into Hyannis, and the autopilot tracked the localizer and glideslope like it was on rails!

I taxied to Griffin, walked into the office, and sheepishly explained my embarrassing situation to Ray Berry who heads up Griffin’s autopilot shop. I realized that Griffin’s autopilot hotshots could hardly be expected to troubleshoot a problem that they couldn’t reproduce. They pulled the computer and torture-tested in on the bench for an hour, but couldn’t find anything wrong. They reinstalled the computer and I flew back to Norwood. Once again, NAV-mode worked fine. (Intermittent problems are always the hardest to troubleshoot.)

But wait…there’s more!

On Sunday, I decided to take the airplane up for an hour-long test flight to see whether I could get the autopilot to fail again. I programmed my Garmin 530 for a complex 8-leg route involving a whole series of turns and course changes. I departed Norwood, engaged NAV-mode, and watched as the 400B flew the complicated maze perfectly, tracking the course centerlines and turning left and right at all the right times.

Then, on the final leg of the flight back to Norwood, the left ALT FAIL light came on. (Are you kidding me?) I checked the left alternator with the aircraft’s voltammeter and indeed it wasn’t putting out any current. Great!

After landing, I retrieved the little test meter from the toolkit I always carry in my wing locker and measured the resistance across the left alternator field. It read zero ohms…a dead short! On a hunch, I climbed into the cockpit and removed the left alternator field fuse from its fuseholder. Sure enough, it was blown. Hmmm…

I grabbed some tools from my toolkit, and removed the right half of the nose bowl so I could gain better access to the alternator. I disconnected the two field wires from the alternator field terminals, then measured the resistance across the alternator field terminals once again. Now it read 20 ohms, exactly what it ought to be. This told me that the alternator itself was fine (whew!), and that I was dealing either with a shorted regulator or a short circuit in the field circuit wiring from the regulator to the alternator.

I inspected the wiring and located the problem: a spot where the field wire was chafed and the center conductor was shorted to the shield. I cut the shielded field wire where it was damaged, stripped both ends, and performed a “battlefield repair” with a pair of insulated crimp butt splices. I reinstalled the nose bowl, replaced the blown field fuse with a spare from my toolbox, and fired up the left engine. The left alternator worked just fine now. Another bullet dodged!

Autopilot…again

It was time to move on to my next destination, Cadillac, Michigan. I decided to leave Boston a day early and fly to Grand Rapids in hopes that Bob Weber at Mayday Avionics could figure out what was wrong with my 400B NAV-mode.

During the 3+30 flight to Grand Rapids, the autopilot’s NAV-mode failed just as it had two weeks earlier: Big Left Turn. This was a good thing. If the failure persisted, maybe I could reproduce it on the ground for Bob Weber. As things turned out, it did and I could.

Bob and I did a bunch of troubleshooting with the 400B computer out of the airplane and hooked up with extender cables. Eventually, Bob concluded that the problem wasn’t in the 400B after all. It appeared that the 400B was getting bad analog course deviation signals from the Garmin 530. It appeared that the autopilot troubleshooting at both Griffin and Mayday had been a blind alley. The autopilot itself wasn’t the culprit after all.

By the time I departed Grand Rapids for Cadillac, the working assumption was that the problem was most likely in the Garmin 530. That was bad news, because Garmin no longer repairs older 530s like mine. The best they could offer was to upgrade my 530 to a WAAS-capable 530W. Doing that upgrade would also require me to upgrade my Sandel SN3308 software and replace my GPS antenna and coax. The total tab for all this would be nearly $6,000.

Problem solved?

I flew to Cadillac, then to Oshkosh for AirVenture week, then to Torrington, Wyoming for fuel, then to North Las Vegas, Nevada to drop off passengers. During all those legs—totaling 10 hours—the autopilot NAV-mode failed consistently with Big Left Turn syndrome. Then on the final two-hour leg from Vegas to California, the NAV-mode functioned perfectly.

A few days later, I did a bunch of ground tests and then another hour-long test flight, and I couldn’t get the NAV-mode to fail. Don’t you just hate when that happens?

I still wasn’t 100% convinced that the 530 was the culprit. I came up with an alternate theory: The problem might be with the old remote switching relay that switches the autopilot NAV-mode between GPS #1 (the Garmin 530) and GPS #2 (an ancient II Morrow GX-50). To test this theory, I disconnected the remote relay and substituted a jumper plug that “hardwired” the 530 nav outputs to the autopilot. Since then, I’ve flown more than 20 hours and the autopilot NAV mode has functioned flawlessly. I’m pretty sure my relay theory was correct, in which case I saved myself $6,000.

I just love when that happens.

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: