Mac owned an A36 Bonanza for ten years, but he’d sold it and was now looking to move up to a twin. His online research uncovered a promising purchase candidate, a 1980 Beechcraft E55 Baron, and he knew he’d need a thorough prebuy to find out if this airplane was really as nice as it looked on the web.

Because Mac lived in New England and the Baron was based 900 miles southwest in rural Indiana (a 14-hour drive), Mac engaged Savvy Aviation to manage his prebuy. He knew that a piston twin can be a joy to fly or a financial black hole, depending on whether it’s a peach or a lemon, so he was a bit apprehensive about this purchase. When Mac learned that the SavvyPrebuy program had some 1,000 prebuy examinations under its belt, he felt confident that Savvy probably had the process down to a science.

The task of managing Mac’s prebuy fell to James Watson A&P/IA. In addition to being an experienced Savvy account manager, James owns and operates Watson Aero LLC, a full-service Continental and Lycoming engine overhaul facility in Louisville, Georgia, which also does engine removals and installations and other airframe services. Since powerplant evaluation is a huge portion of every piston twin prebuy, James seemed like an ideal choice.

Selecting the Prebuy Shop

Because of the critical importance of getting a truly independent prebuy, Savvy has a strict policy that the examination must be done by a shop or mechanic that has never worked on the airplane before, and that has no prior relationship with the seller (and/or the seller’s broker if one is involved). To ensure that this is possible, Savvy recommends that its clients require that the seller agree to allow the prebuy to be performed at a location of the buyer’s choice within one hour’s flying time of the aircraft’s home base.

“The Baron is located in a very rural part of Indiana,” Mac told James. “Are there likely to be good shops within an hour’s flight time?”

“There are a number of shops within 100 miles with which Savvy has had good experiences,” James replied. “The question is whether any of them can squeeze your prebuy into their shop schedule. Most good shops tend to be booked out for weeks or months in advance. Plus it’s Christmas week, which means shops will be working a couple of short weeks. I will make a series of inquiries.”

James immediately contacted the Directors of Maintenance of five different shops. He sent each of them Savvy’s prebuy checklist and asked each if they were interested, how soon they could get started, and what it would cost. Two of the shops did not respond at all. A third responded, “we don’t perform prebuys, only full annual inspections in accordance with the manufacturer’s annual inspection checklist plus all instructions for continued airworthiness.” (Lots of shops and mechanics don’t like doing prebuys.)

The two remaining shops both responded quickly, indicated that they were interested in doing the Baron prebuy and could get started promptly after Christmas. Both quoted nearly identical labor charges for completing the prebuy checklist: $2,400. James said he felt especially comfortable with one of them:

“I worked with this shop recently on another prebuy and was happy with their performance,” James told Mac. “Their labor quote is fair and competitive, and their availability is quick. I recommend we get on their schedule, and I will do so with your approval.”

Staying Flexible

“Sounds good to me,” replied Mac, “but I submitted my offer to the seller’s broker this morning and have not yet heard back. I imagine the seller and I should be able to agree on a price and sign a conditional purchase/sale agreement within the next few days. I would like to schedule the prebuy as long as the shop is aware that we may need to cancel if I’m unable to reach an agreement with the seller.” James notified Ed (the shop’s Director of Maintenance) of the situation, and Ed agreed to put Mac’s prebuy on the shop schedule starting the Monday after Christmas.

Two days later, Mac reported that he’d reached agreement with the seller, but that the airplane would not be available to fly to the prebuy shop until after the holidays. James contacted Ed, and Ed agreed to reschedule the prebuy to start on Monday, January 4th.

By the Monday after Christmas, the plans had firmed up. Mac and the seller had signed the conditional purchase/sale agreement. The seller had made arrangements with a professional pilot to deliver the airplane to the prebuy shop on Sunday, January 3rd. Mac would be traveling to Indiana to meet the pilot, and the two of them would test-fly the Baron first thing Monday morning before the shop started the prebuy examination. Mac had obtained a test-flight checklist from the American Bonanza Society.

“Be sure to keep detailed notes of any discrepancies you notice during the test flight,” James advised Mac, “because certain issues only present themselves in flight and can’t be reproduced during a ground run (which the prebuy shop will be doing). We want to be sure that any and all potential issues are identified so they can be corrected.”

Then Mac received a call from the broker who said the airplane couldn’t be delivered to the prebuy shop on Sunday as planned. Turns out that the pilot had extended his holiday vacation to avoid inclement weather, and wouldn’t be returning until sometime Monday. The new plan was for him to deliver the plane Tuesday evening and make it available to the shop on Wednesday. This threw a monkey wrench into Mac’s plan to get there for a test flight, so he decided he’d test-fly the plane after the prebuy examination assuming it went well. James contacted Ed to explain the latest change of plans, and Ed said he’d be standing by to jump on the airplane Wednesday morning.

Finally, the stars came into alignment. Ed confirmed to James that the Baron arrived on Tuesday and the prebuy exam would be starting Wednesday morning.

Phase One

Savvy always divides its prebuy examinations into two phases. During Phase One, we ask the prebuy shop to conduct its research of the aircraft’s maintenance records and to go over the powerplant(s) with a fine-tooth comb. If, and only if, this phase is completed without finding any show-stoppers do we ask the shop to continue to Phase Two which covers the airframe and avionics.

We structure things this way in order to maximize the chance of finding any big-ticket problems as early as possible. Unlike an annual inspection (which is always performed to completion), when doing a prebuy we always want to make sure that we can hit the “stop” button the moment any serious red flag is uncovered, and not hit “resume” unless and until the buyer and seller have come to agreement on how to deal with the discrepancy. The idea is to minimize our client’s expense if the airplane turns out to be a lemon and the client winds up walking away.

“Please send the Phase One discrepancy report once you’ve completed that portion of the checklist,” James said to Ed on Wednesday afternoon.

Early Monday morning, Mac contacted James: “I don’t mean to pester, but is it common to be three days into a prebuy without a progress report?”

James explained that for a twin it usually takes several days to complete the Phase One examination and write up the findings, because the plane has two engines and propellers that need to be gone over. He also pointed out that most shops were closed on weekends. Right after lunchtime, James sent Ed a ping asking for a progress report.

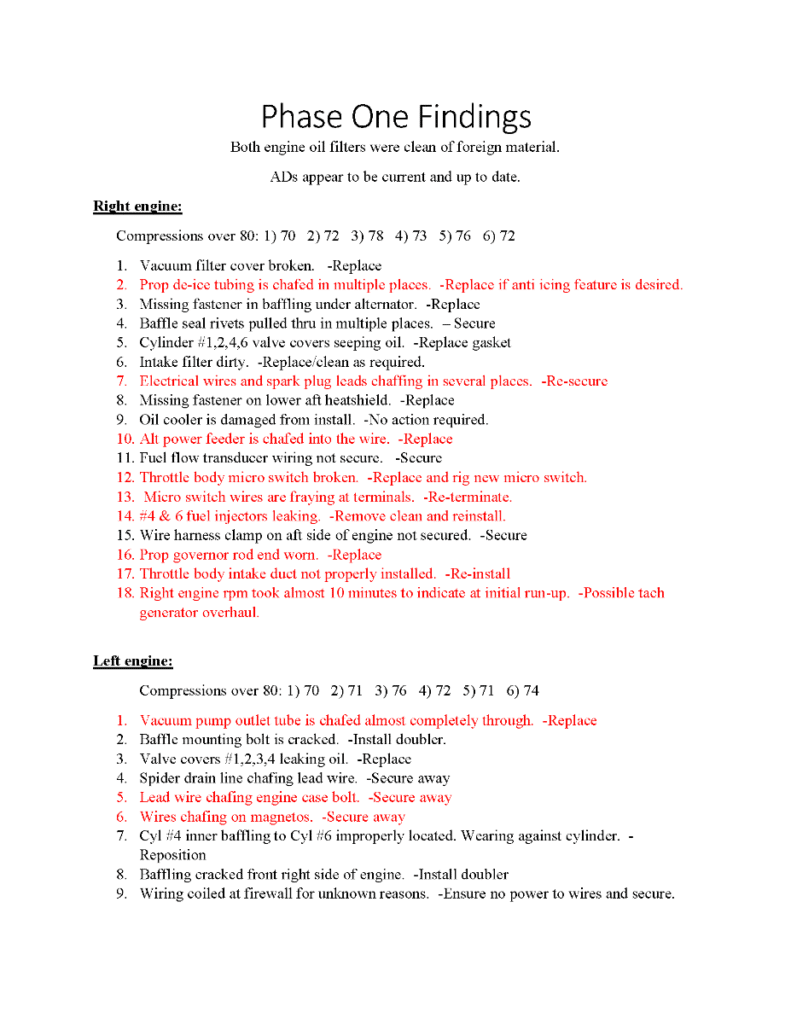

“I was just about to send the Phase One discrepancy list to you,” replied Ed, attaching a detailed report:

The good news was that both engines had excellent compressions, clean oil filters, and all ADs complied with. The bad news was that the report listed 27 discrepancies—18 for the right engine and 9 more for the left engine—with a dozen highlighted in red to indicate items that Ed considered to be airworthiness discrepancies.

Airworthiness Discrepancy?

Keep in mind that a prebuy examination isn’t an “inspection” in the regulatory sense (at least it shouldn’t be), and the mechanic conducting it is not being asked to make a regulatory determination of airworthiness the way he would be if he were performing an annual inspection. In the context of a prebuy, an “airworthiness discrepancy” means one that the mechanic finds sufficiently serious that he could not sign off an annual inspection as airworthy unless it was corrected.

The seller is theoretically expected to pay the cost of correcting any airworthiness discrepancies found during the prebuy, while the cost of correcting other discrepancies is generally the responsibility of the buyer. When buying a used airplane the buyer is not entitled to receive a perfect (discrepancy-free) airplane, but he is entitled to receive an airworthy one. At least that’s the theory. In practice, who pays for what is usually the subject of final price negotiations between the buyer and seller once the prebuy findings are in.

“I do not see any show-stopper issues here that would cause me to suggest we terminate the prebuy now,” James told Mac after reviewing the Phase One findings. “I recommend (if you approve) that we ask the shop to proceed with Phase Two and give us a complete report. I will then go over that report with you and make recommendations about what items the seller should be responsible for.”

Meantime, Ed followed up regarding the propellers: “Both propellers were overhauled in 2004, and are currently at 2,183 hours and 17 years since overhaul. Hartzell recommends overhaul at 2,400 hours or 6 years, whichever comes first.” (Savvy generally considers the six-year overhaul recommendation to be excessive unless the aircraft lives in an environment with unusually high corrosion risk.)

“I don’t see anything scary,” Mac agreed. “Let’s proceed to Phase Two.”

Phase Two

“Please proceed with Phase Two,” James told Ed, “and provide us with your complete report when finished. The buyer would like a rough estimate of when you expect to be completed. Also, could you confirm that you were able to perform a borescope inspection of the cylinders?”

Ed confirmed that the borescope had been done and the cylinders all exhibited good cross-hatching with no signs of excessive wear or burned valves.

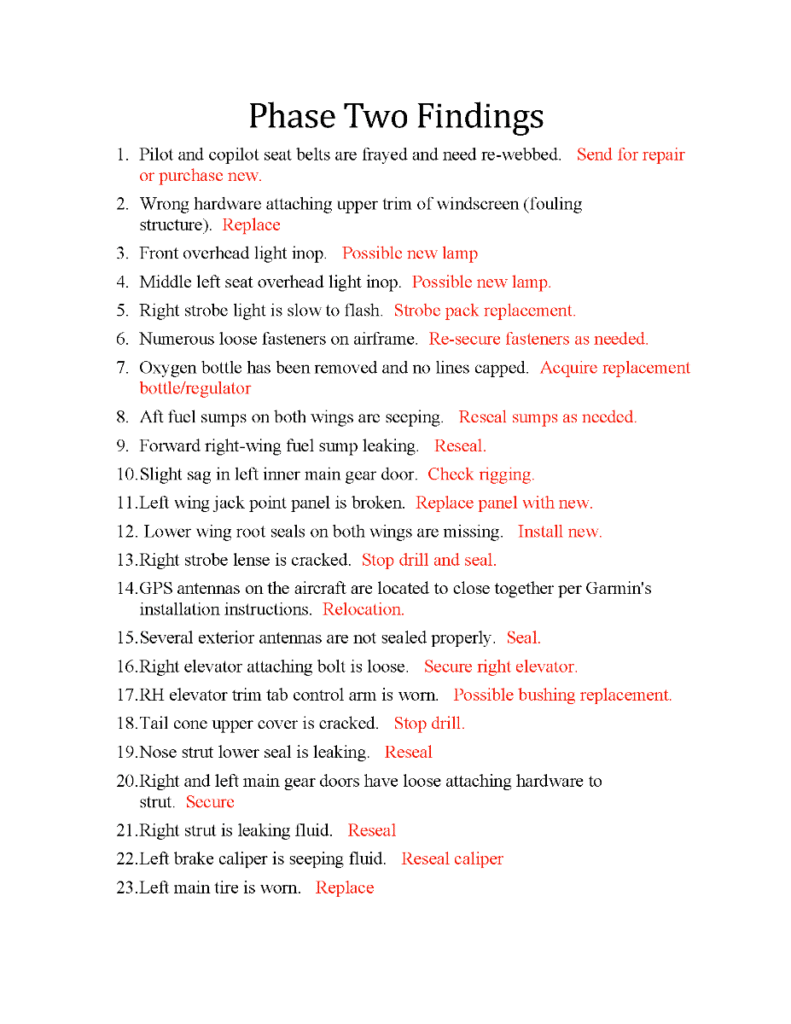

Three days later, Ed sent his Phase Two report:

Oh boy! There are a lot of discrepancies here,” Mac remarked to James. “Sure makes me wonder how carefully the plane was maintained?”

“There are definitely some issues that need to be addressed here,” replied James, “but still nothing I would consider to be a show-stopper. My recommendation would be to ask Ed to provide cost estimates for repairing the airworthiness items, and then present them to the seller.”

James listed the airworthiness items as follows:

Right Engine

- Prop deice tubing, replace.

- Cylinder #1/2/4/6 valve cover gaskets, replace

- Induction air filter, replace/clean

- Electrical wires and spark plug leads chafing, secure

- Alternator power feeder chafed into wire, replace

- Fuel flow transducer wiring, secure

- Throttle body microswitch, replace and rig

- Microswitch wires, replace terminals

- Fuel nozzles #4 and #6, remove/clean/reinstall

- Prop governor rod end, replace

- Throttle body intake duct, reinstall

- Tach generator, overhaul

Left Engine

- Vacuum pump outlet tube, replace

- Cylinder #1/2/3/4 valve cover gaskets, replace

- Spider drain line, secure

- Lead wire chafing on engine case bolt, secure

- Wires chafing on magnetos, secure

- Cylinder #4/#6 intercylinder baffle, reposition

- Cracked front right baffle, install doubler

Airframe

- Pilot/copilot seat belts, re-web or replace

- Front overhead light, replace lamp

- Middle left overhead light, replace lamp

- Right strobe, replace power pack

- O2 bottle/regulator missing (not airworthiness issue, but seller should address)

- Aft fuel drains on both wings, reseal

- Forward fuel drain on right wing, reseal

- Left inner main gear door, re-rig

- Left wing jack point panel, replace (not airworthiness issue, but seller should address)

- Exterior antennas, reseal (not airworthiness issue, but seller should address)

- Right elevator attach bolt, secure

- Right elevator trim tab control arm, replace bushing

- Nose gear strut, reseal

- Both main gear doors strut-attach hardware, secure

- Right main gear strut, reseal

- Left brake caliper, reseal

- Left main tire, replace

“Okay, let’s ask Ed for an estimate to address the airworthiness items and the other items you’ve flagged as seller’s responsibility,” said Mac. “Can we also ask Ed for an estimate of what it would cost (in time and dollars) to convert the prebuy exam into an annual inspection?”

James asked Ed to work up the cost estimates.

“Do you see any downside in sharing the shop’s lists with the seller ahead of receiving the estimate?” Mac inquired.

“No harm in sharing the list,” James indicated

Just Dollars Away

Days passed. Mac was getting impatient. James pinged Ed. Ed apologized for the delay, and forwarded labor estimates for all the discrepancies, but missing some parts pricing that hadn’t yet been received from various suppliers. Most of the discrepancies would be inexpensive to fix, but there were a number of expensive ones. Mac shared this information with the broker, who shared it with the seller.

Meantime, Ed also provided the requested estimate to convert the prebuy into an annual that was nearly $4,200. “That would bring the combined cost of the annual inspection to $6,500, which seems pretty high to me,” James told Mac.

“Yes, I think I’ll pass on having them do the annual,” replied Mac. “The annual isn’t due until May, and a couple of months of flying might uncover some additional issues that I’d like addressed when the airplane goes into annual. I also think I’d prefer to use the annual as an opportunity to build a relationship with a shop near my home base.”

“I agree 100%,” said James. “That’s a good plan.”

“I spoke to the broker last evening,” Mac continued. “He is going over the list of discrepancies with the seller, and thinks the seller may prefer to address all the airworthiness issues before the test flight to avoid liability if something goes wrong. The broker and I will speak again later today and I should have more information about the seller’s intentions.”

Will the seller agree to pay to correct the airworthiness discrepancies? Will Mac get to test-fly the Baron? Will he end up buying it or walking away? We wish we could tell you, but the last chapter of this saga is still unfolding.

We’re sharing this with you anyway because it’s a good illustration of how Savvy works with prospective buyers to guide them through the process of finding a suitable prebuy shop, defining the scope of the examination, interpreting the findings, determining which discrepancies the seller should be asked to address, and guiding the buyer through final price negotiations and closing.

Mac’s prebuy also underscores the notion that buyers shouldn’t be scared off by a long list of discrepancies as long as it doesn’t contain any major show-stoppers that can’t be resolved through negotiation as to who is going to pay for what. Frankly, if a prebuy examination of a 40-year-old twin yielded a short discrepancy list, it would most likely indicate that the prebuy shop wasn’t looking very hard.

(For a prebuy examination, you want to choose the most thorough, nit-picky, obsessive-compulsive, zero-tolerance inspector you can find. For an annual inspection, maybe not so much…)

Having a veteran A&P/IA like James to guide you through this thorny thicket can really help put things into proper perspective. On one hand, it can help protect you from buying a lemon; on the other hand, it can help prevent you from walking away from a nice solid airplane with numerous but easily manageable issues (many of which you can probably convince the seller to pay for).

Something to think about if you’re in the market for a pre-owned aircraft.

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: