Does your engine REALLY need to be euthanized?

“I’m in trouble. Can you help?”

The owner of the vintage Mooney was obviously stressed. He identified himself as a highly experienced military pilot but a first-time aircraft owner who’d recently flown his airplane to Florida on business.

When it came time to return home, the Mooney’s Lycoming IO-360 wouldn’t start. He took it into the local shop on the field, who discovered that the left magneto’s case had cracked. Since the left magneto is the one used to start the engine in this airplane, that seemed to be the smoking gun that would explain why it wouldn’t start. The shop proposed to order a replacement magneto, and the owner approved.

“Now they’re telling me the engine needs to be torn down!” he told me in a panic-laced voice. “It’s nowhere close to TBO, and I really can’t afford an overhaul right now.”

“Why does the mechanic think the engine needs a teardown?” I queried, finding it hard to imagine how a bad magneto could justify something so drastic.

The owner explained to me that when the A&P removed the damaged left magneto, he observed that two of the steel balls from the magneto’s drive-end ball bearing were missing and concluded that they must have fallen into the engine. The mechanic said that an engine teardown would be needed to locate them.

I wasn’t buying it. Why are so many A&Ps spring-loaded to the teardown position?

Missing Balls

“Let’s think about this,” I said to the frazzled owner. “Did the two bearing balls go missing while the engine was running, or did it happen while the mechanic was removing the magneto?” The owner said he didn’t know, but that the engine seemed to be running perfectly during his flight to Florida, and never ran after that.

“If those two bearing balls fell into the engine while the A&P was removing the mag, it seems to me that would be no big deal,” I offered. “The balls might either come to rest at the bottom of the engine accessory case or might fall all the way into the engine’s oil sump. Either way, they’d be out of harm’s way and in no position to do any mischief. What’s the problem?”

“What if they got sucked into the oil pump?” asked the owner.

“That can’t happen,” I explained. “The oil pickup tube is protected by a suction screen that prevents anything larger than about a millimeter in diameter from entering the pump. There’s no way a bearing ball from the magneto could pass through that screen and damage the oil pump. It would just sit in the sump, mind its own business, and not bother anything.”

“I’ve seen a whole lot worse than a couple of bearing balls fall into engines,” I continued. “Just be glad it wasn’t a shop rag or paper towel that could get wrapped around the suction screen and obstruct oil flow. A bearing ball in the sump is basically a harmless stowaway.”

“Oh, and the impact on weight-and-balance is negligible,” I joked, attempting to lighten the owner’s mood.

“So, you’re saying that there’s no risk?” he said.

“Well, the main risk would be if the bearing balls fell into the accessory case while the engine was running and got tangled up with the gear train on their way down,” I said. “I would suggest that while the mags are off, somebody take a close look at the gears to make sure there aren’t any chipped teeth or other damage. Have them rotate the prop to make sure they can see all the gear teeth. Have them use a borescope if needed to get a good look. If there’s no damage to any of the gears—and I’m betting there isn’t—then I suggest you have them install the new magneto, make sure the engine starts okay, and then fly home with a smile on your face.”

Our hero contacted me a few days later to tell me that he’d passed all this on to the Florida A&P, who to his credit saw the logic in what the owner was telling him. The mechanic carefully inspected the gear train, found no damaged gear teeth, installed the replacement magneto, and ran up the engine which started perfectly. The owner then flew home uneventfully, much relieved, with budget intact.

There might be a couple of bearing balls at the bottom of the Lycoming’s oil sump. Or maybe not. Who knows? Who cares? If they’re there, they’ll still be there someday in the hopefully distant future when the engine eventually gets overhauled. I suspect the overhaul shop won’t even think twice about finding them there, because they’ve seen far worse lying at the bottom of oil sumps of fine-running engines.

Continental Cam

Not long afterwards, I heard from a Skylane owner who was clearly shaken.

“My Cessna 182 is in annual, and my IA found one cylinder with low compression (38/80), so with my approval he pulled the cylinder. Now he’s telling me that the cam is toast and the O-470-U needs to be overhauled or replaced! What should I do?”

I didn’t have the heart to tell this owner that he shouldn’t have approved the cylinder removal and thereby opened Pandora’s box. According to the guidance in Continental Manual M-0, the appropriate response to a cylinder with low compression is to perform a borescope inspection to determine the cause of the low compression. If the cylinder looks okay under the borescope, then Continental says the engine should be flown for a minimum of 45 minutes and the compression test repeated with the cylinder hot. In my experience, this almost always results in a compression reading 10 to 20 points higher, usually enough to exceed the no-go threshold.

In fact, I had one client with an SR22 based in Florida whose Continental IO-550-N had a cylinder that measured 38/80 at annual. The IA wanted to pull the jug, but I insisted that the Continental guidance be followed to the letter. The IA reluctantly buttoned up the airplane and let the owner take it up for a one-hour flight. When the airplane landed and taxied to the maintenance hangar, I made sure the IA was standing by to pull the cowl, remove the top spark plug, and perform the retest quickly. This time, the cylinder measured 72/80 and the cylinder escaped euthanasia.

Sadly, the Skylane owner had contacted me too late for me to prevent the cylinder from being pulled, so now I had to deal with the reality of the exposed cam that his IA was claiming to be toast. Once again, Continental came to the rescue with its Service Information Directive SID05-1B which provides detailed inspection guidelines for Continental camshafts and lifters. (Google it!)

This nine-page service bulletin is chock full of photos showing what normal, distressed, and unairworthy cam lobes and lifter faces look like. Continental’s stated criterion for an unairworthy cam lobe is “the presence of indentions or crack-like features in the surface along the cam lobe apex” which have sufficient depth to “repeatedly catch” the tip of a sharp pick or awl. Anything less is considered acceptable.

For borderline cases, Continental believes in letting the cam decide its fate: “For minor distress, the camshaft may be continued in service and re-examined upon the accumulation of 100 hours operation or 12 months, whichever occurs first.”

I asked the Skylane owner to email me a high-resolution photo of the cam lobe that had his IA’s knickers in a twist. The photo revealed a cam lobe with some obvious corrosion pitting but definitely no “crack-like features” or large indentations on lobe’s apex. My advice to the owner was to sit down with his IA, go over the SID05-1B guidance, and try to persuade him that the appropriate action was to install a new lifter and re-examine it after 100 hour or 12 months to see if it was torn up by the cam (which is the cam’s way of saying “I’m toast”). If the lifter survives, then the cam is exonerated.

It’s important to understand that there’s really no risk in taking this approach. Nobody ever fell out of the sky because of a spalled cam lobe or spalled lifters. I like to tell owners “this isn’t a safety-of-flight issue, it’s strictly a safety-of-wallet issue.”

I was pleased to learn that the Skylane owner’s IA agreed to this plan. A year from now, we’ll find out which way the cam voted. So very democratic!

Lycoming Making Metal

Another Skylane owner emailed me, this time about a Cessna T182T with a Lycoming TIO-540-AK1A engine:

“Mike, please help me! My engine is 300 hours over TBO, makes good power and all compressions are in the mid-70s. But it has started making metal. There are chips in the screen and metal in the filter. I don’t want to replace the engine since it runs so well.”

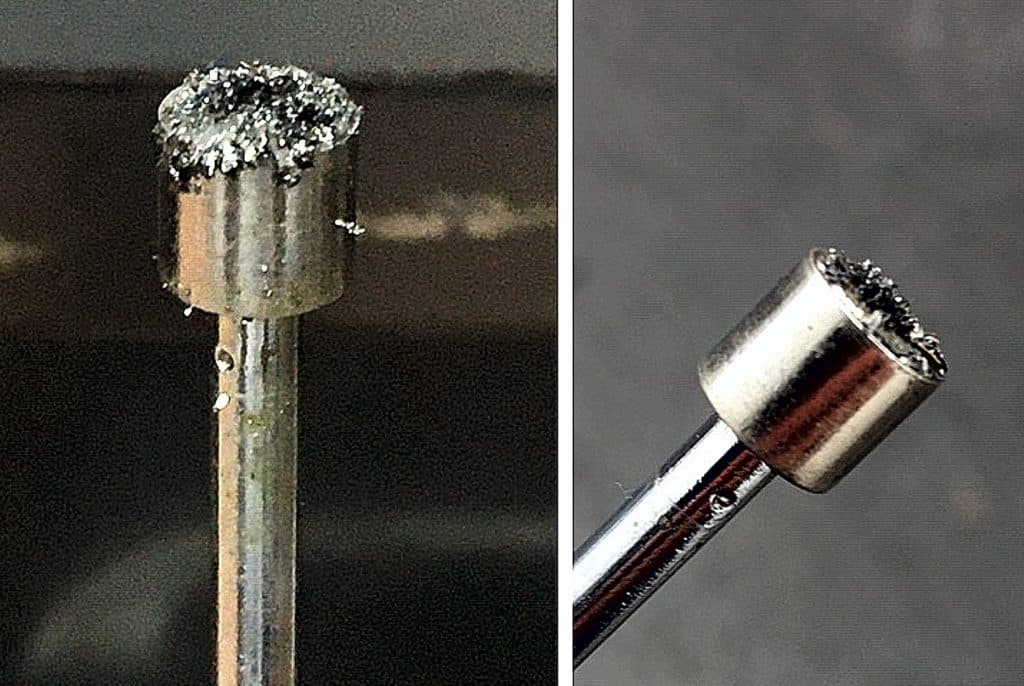

The email contained two photos of metal chips adhered to a magnet. “The quantity of metal has decreased from the first oil change to the next one,” the owner said. He also included a report from Aviation Laboratories in Houston indicating that the chips were alloy steel consistent with AMS 6414 or 6415. Clearly, this fellow was doing his homework.

I was not terribly optimistic about the prospects for saving this engine. I had to give the owner the bad news: AMS 6414/6415 is low-alloy Chromium-Nickel-Molybdenum steel that almost certainly was coming from one or more cam lobes. However, the fact that the quantity of metal seemed to be decreasing was somewhat encouraging. Because I don’t consider cam distress as a safety-of-flight issue, I recommended against jumping to any expensive conclusions.

I referred the owner to Lycoming Mandatory Service Bulletin 480F titled “Metallic Solids Identification After Oil Servicing, and Associated Corrective Action.” This service bulletin that provides very specific recommendations for what action to take when metal is found in the oil filter or suction screen. I love SB 480F because it takes such a thoughtful and measured approach. It is the perfect antidote for IAs that want to condemn an engine to euthanasia because a dozen metal flakes were found in the filter. (SB 480F says to fly another 25 hours and re-check the filter to determine which way the needle is moving.)

I recommended that the owner continue to fly the engine, but to re-check the filter and screen frequently following the guidance in SB 480F. I advised that so long as the quantity of metal appeared to be decreasing he should continue to fly and monitor, but if appeared to be increasing he should be prepared to overhaul or replace the engine.

I also told him that for most Lycoming engines, it was possible to inspect at least a few cam lobes by inserting a borescope into the oil filler or dipstick openings. I said I thought it would be worthwhile to try to visually inspect the cam in this fashion before making a decision whether to tear the engine down or continue it in service.

I don’t know the punch line on this engine yet, but if I were a betting man I would bet this engine will meet its maker sooner rather than later. I really hate to see engines euthanized before their time, but for this one its time may be near.

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: