Situational awareness requires being aware of your aircraft’s systems, too.

On Saturday, August 26, 2022, a young CFI took off from Monterey, California in a Cessna 172 on a “Discovery Flight.” His passengers were a young couple, with the man occupying the left front seat and the woman seated in the back. The CFI occupied the right front seat. The airplane leveled off at 3,500 feet, at which point the CFI turned the controls over to the male passenger and started giving him basic instruction. The flight proceeded first north, then west following the coastline to Santa Cruz, did some maneuvers and airwork, then turned southeast to return to Monterey.

Not long afterwards, the CFI sensed that the engine was losing power, and the tachometer confirmed this. He quickly ran through the memory items on his loss-of-power checklist: pitch to best-glide speed, mixture full rich, primer locked, carb heat on, fuel selector set to BOTH, etc. None of this helped, and the engine continued to lose power and RPM.

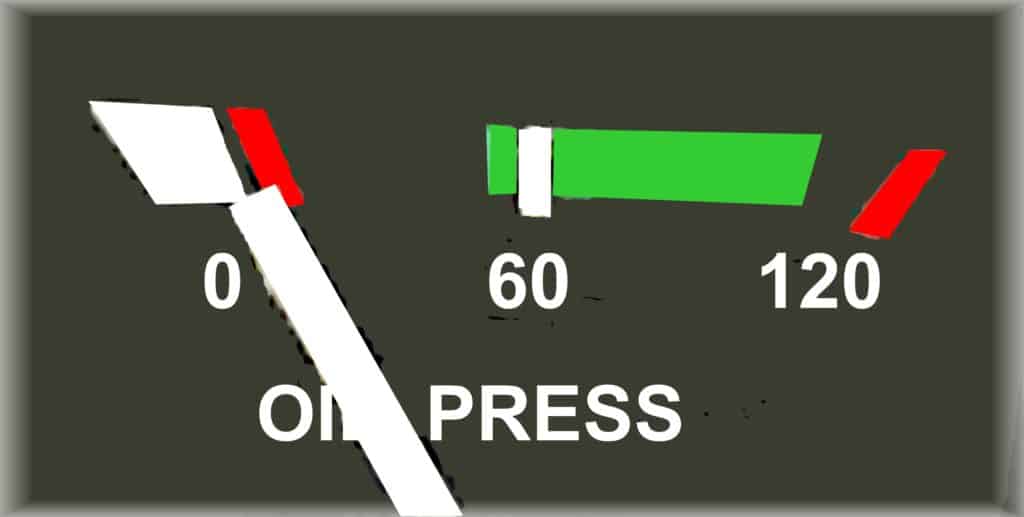

At this point, the CFI looked at the oil pressure and temperature gauges. The oil pressure gauge read zero!

The CFI advised NORCAL Approach that he had an engine emergency. Approach issued a vector to the nearest airport, which was Watsonville (WVI). The CFI turned toward WVI.

Then the engine seized, and the prop stopped.

The CFI made multiple attempts to restart the engine, but the starter was only able to get the prop to twitch slightly. Ultimately, these unsuccessful restart attempts drained the battery to the point that the avionics shut down. Also, the vacuum punp was not turning so the attitude indicator rolled over and died.

Forced Landing

The CFI realized that he had no chance of making WVI, and started looking for a Plan B. His first thought was the Pacific Coast Highway, but he could see that it had heavy automobile traffic and a lot of overpasses, making a successful forced landing on the highway unlikely. So, he decided his best option would be to attempt a landing on the beach, which was obscured by a thick marine layer of low clouds.

Fortunately, the CFI had ForeFlight running on his iPad coupled via Bluetooth to a battery-powered Stratus ADS-B receiver with internal AHRS. He configured his iPad display to show a simulated six-pack instrument cluster on the top half of the screen and a moving-map sectional chart on the bottom half. With the help of this display, the CFI headed toward the beach and made a deadstick descent into the cloud tops at 1,600 feet.

When he finally broke out of the clag at 400 feet, the CFI saw nothing but ocean in the windshield. Then he looked across the cabin and spotted the beach out of the lefthand window. He made a left turn toward the beach and made a perfect deadstick no-flap landing on the wet sand. (The flaps were inoperative because the battery was depleted.) There was no damage to the airplane or any of its three occupants, although the female passenger in the back seat was visibly shaken by the harrowing experience. Who could blame her?

Upon egressing the airplane, the CFI noted that the fuselage belly and empennage were covered with engine oil. There was no oil visible on the dipstick.

Anything Wrong With This Picture?

While listening to the young CFI being interviewed on YouTube shortly after the incident and looking at his FlightAware ground track, I couldn’t help but admire how he kept his cool under pressure and made a series of good decisions that resulted in a great outcome.

Yet there were a couple of aspects of his story that I found disturbing.

Even though the CFI was flying from the right seat with the engine gauge cluster smack dab in front of him, he didn’t notice the loss of oil pressure until the engine was literally on the verge of seizing and the gauge was reading zero. How long had the oil pressure been below the bottom of the 55-95 PSI green arc? Why didn’t the CFI notice it earlier? If he had noticed it earlier, could he have throttled back to low power and prevented the engine from seizing? Or at least delayed the seizure? Could he have limped to an on-airport landing at WVI if he’d detected the situation earlier?

Once the engine did seize and the prop stopped, why did the CFI attempt to restart it with the starter motor—not just once, but repeatedly until the ship’s battery was depleted and electrical power to the avionics and flaps was lost? While I’m sure that a restart attempt is on the power-loss checklist, it is obviously an exercise in futility with an engine that seized due to systemic lubrication failure. Visualize the CFI stretching to reach the key switch located he extreme left size of the panel to turn it to the START position. How much precious time was lost doing these multiple futile restart attempts? Wouldn’t it have been better to focus on aviating, navigating and communicating?

Both of these things—late recognition of loss of oil pressure and multiple attempts to restart the seized engine—strike me as indicating lack of situational awareness of the aircraft systems on the part of the CFI. Certainly, his situational awareness with respect to aerodynamics and navigation was nothing short of superb—but with respect to aircraft systems, not so much.

Look, I fully realize that almost all pilots (including me) don’t scan the engine gauges as often as we should. So, I’m not really surprised that this obviously excellent CFI failed to notice that the oil pressure gauge had dropped below the green arc. That’s why I’m convinced that every airplane should be equipped with a digital engine monitor that has lots of sensors (including oil pressure and temperature) and has user-programmable alarm thresholds so that the pilot will be alerted whenever any critical engine parameter goes outside of normal operating limits.

The green arc for oil pressure is 55-95 PSI for most Lycomings and 30-60 PSI for most Continentals. In my opinion, pilots should receive both visual and aural alarms anytime oil pressure is outside those limits while the aircraft is in flight. This is a condition that the pilot needs to know about RIGHT NOW!

With respect to the futility of trying to crank a seized, oil-starved engine until the battery is depleted, this seems like a training deficiency and a power-loss checklist that needs a little tweaking.

Proving The Point

Literally as I was about to sit down at my computer to write this column, my phone rang. The caller was an emergency room physician who owns a Piper PA-28-236 Dakota and was seeking my advice regarding an engine change. I asked the doc why he was replacing the engine, and here’s what he told me…

The airplane had just come out of annual inspection at the FBO where the plane had been maintained since the doc first bought it. The doc invited the two A&Ps who had worked on the airplane—a father and son team—to go up with him on the post-maintenance test flight, and the mechanics said they’d love to do that. (If I ran the FAA, I would make it a regulatory requirement that the IA who signs off an annual inspection go up on the first flight after maintenance.)

The elder A&P occupied the right front seat, and his son was in a back seat. Engine start, taxi, and runup checks were all normal. The doc climbed to cruising altitude and remained in the vicinity of the departure airport.

“Hey,” the elder A&P said over the intercom, “that OIL annunciator light is illuminated. It shouldn’t be!” The Dakota was factory equipped with a small annunciator panel under the glareshield, and the OIL light indicates that oil pressure is low.

The doc told me that he didn’t notice the OIL light until the A&P pointed it out t him. He immediately turned towards the airport and advised the tower that they had an engine issue and were returning to the airport. The tower cleared the Dakota to land on any runway, and revoked the landing clearance for a couple of other aircraft who were in the pattern.

As the Dakota arrived at a downwind leg midfield, the engine seized and the prop stopped. The doc made a deadstick landing on-airport with no damage to the airplane other than an engine that had thrown a rod through the side of the crankcase and was now an expensive paperweight.

The doc told me that had the A&P not noticed the OIL annunciator when he did, the airplane would almost certainly have made an off-airport landing and the outcome would very likely have been much worse.

As you probably guessed, this was a maintenance-induced failure. The younger A&P failed to properly tighten one of the hoses running from the engine to the oil cooler, and it vibrated loose in flight. The mechanic immediately fessed up to his mistake, and the FBO promised to make things right for their longtime customer.

The moral of these stories: Unless you are fortunate enough to have your IA in the right front seat focusing on the engine instruments while you’re focused on flying the airplane, you really need a good digital engine monitor with lots of sensors and user-programmable alarms.

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: