“There appears to be a spike in the #5 CHT on the most recent flight of our SOCATA TB-20 Trinidad,” Mark wrote on his SavvyAnalysis Pro ticket. “The plane seemed okay afterwards, but the #5 EGT is now running higher than normal. Could you take a look, please?”

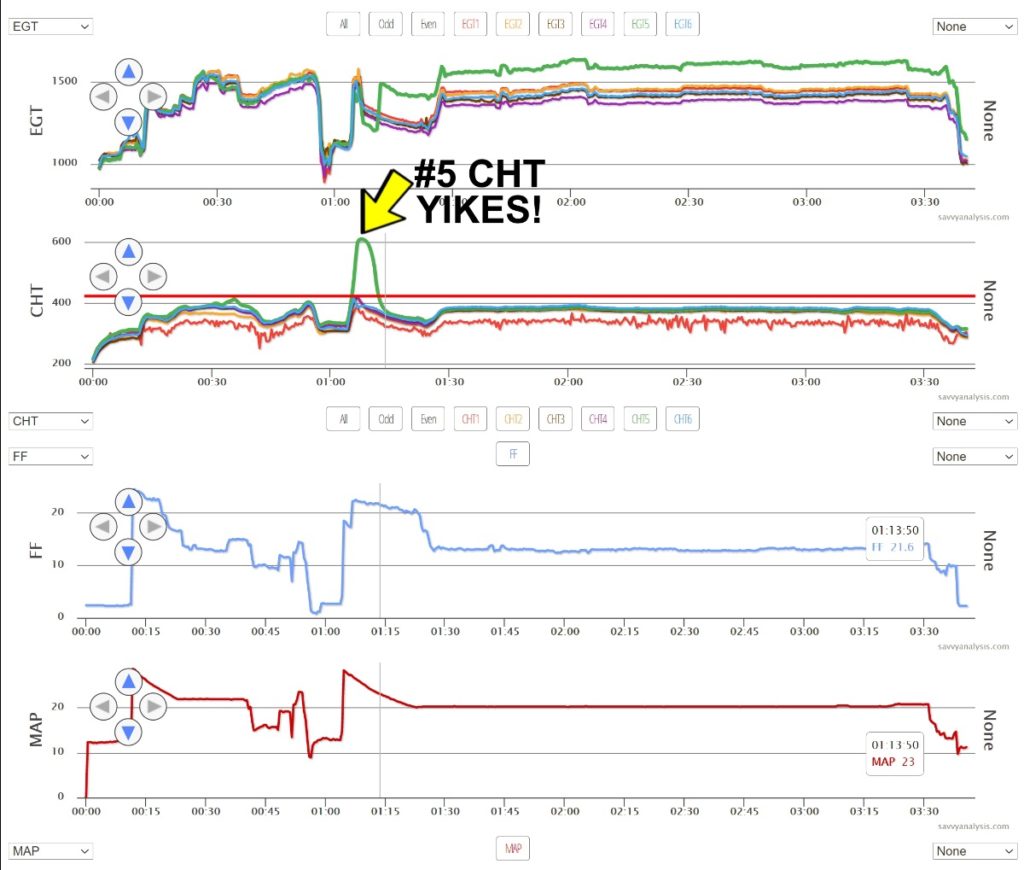

Savvy’s chief analyst Joe Godfrey decided to look at this one himself rather than hand it off to one of his team of analysts. When he pulled up the flight in question, here’s what he saw:

Studying the data of this three-and-a-half-hour flight, it appeared to Joe that the engine was running fine for the first hour of the flight, at which point the pilot made what looked like a touch-and-go landing. When executing the “go” portion of the touch-and-go, it looked like the pilot forgot to set the mixture control to full-rich. This resulted in a rapid rise of all six CHTs on the Lycoming IO-540, with the #5 cylinder going into a serious thermal runaway in what looked almost certainly like a pretty severe detonation event.

The pilot—who Joe learned was Mark’s airplane partner—recognized his mistake about two-and-a-half minutes after takeoff. He shoved the mixture full-rich but did not throttle back. That wasn’t enough to stop the thermal runaway, which continued until the #5 CHT topped out at 610℉—that’s 110 degrees above Lycoming’s redline—and then slowly came back down to normal.

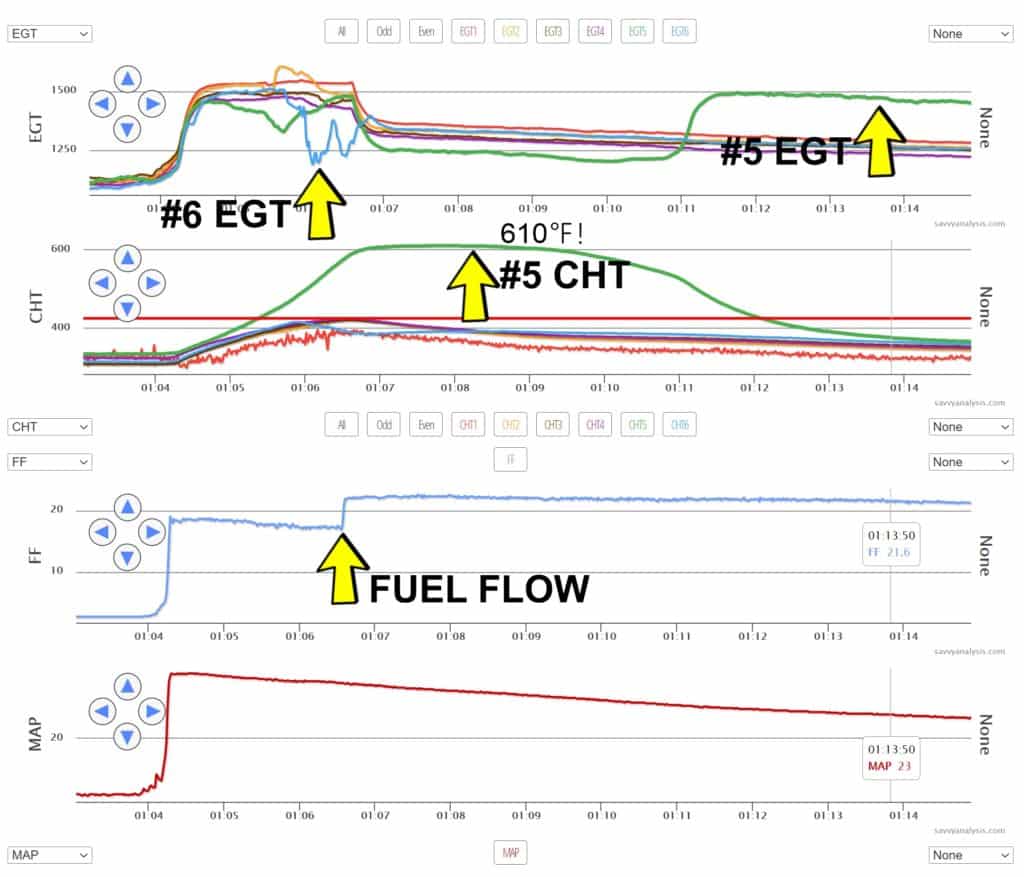

Joe decided to zoom in for a closer look at the event:

He observed that the #5 EGT started declining as the #5 CHT was rising into the danger zone. This proved that the thermal runaway was real, not just a bad CHT probe or some other instrumentation issue. The #6 cylinder was lean enough to start dropping out, while the #5 was at just the right mixture to go into detonation. Even more worrisome, #5 CHT remained in the danger zone for a full six minutes.

Collateral Damage?

Once the thermal runaway resolved and #5 CHT normalized, the #5 EGT did not normalize, but rather rose to stabilize at a value roughly 200℉ higher than normal and this persisted for the rest of the flight. Joe felt that this likely meant that the detonation event damaged something in the cylinder, although he couldn’t tell exactly what was damaged.

It might have just been a spark plug that was damaged enough to quit firing—although a 200℉ rise in EGT is more than usual for one-plug operation—or it might have been something more serious. Joe was worried.

“I’m concerned that the #5 cylinder may have sustained significant damage from the detonation event,” Joe told Mark. “I would urge you to perform a thorough borescope inspection of the cylinder before further flight.”

Good to go?

A couple of days later, Mark gave Joe an update.

“My mechanic and I borescoped the #5 cylinder but didn’t see anything worrisome. The bottom spark plug was clogged with debris, but once my mechanic cleaned it up it looked like new. He thinks the fouled bottom plug probably accounts for the elevated #5 EGT, and approved the airplane for return to service.”

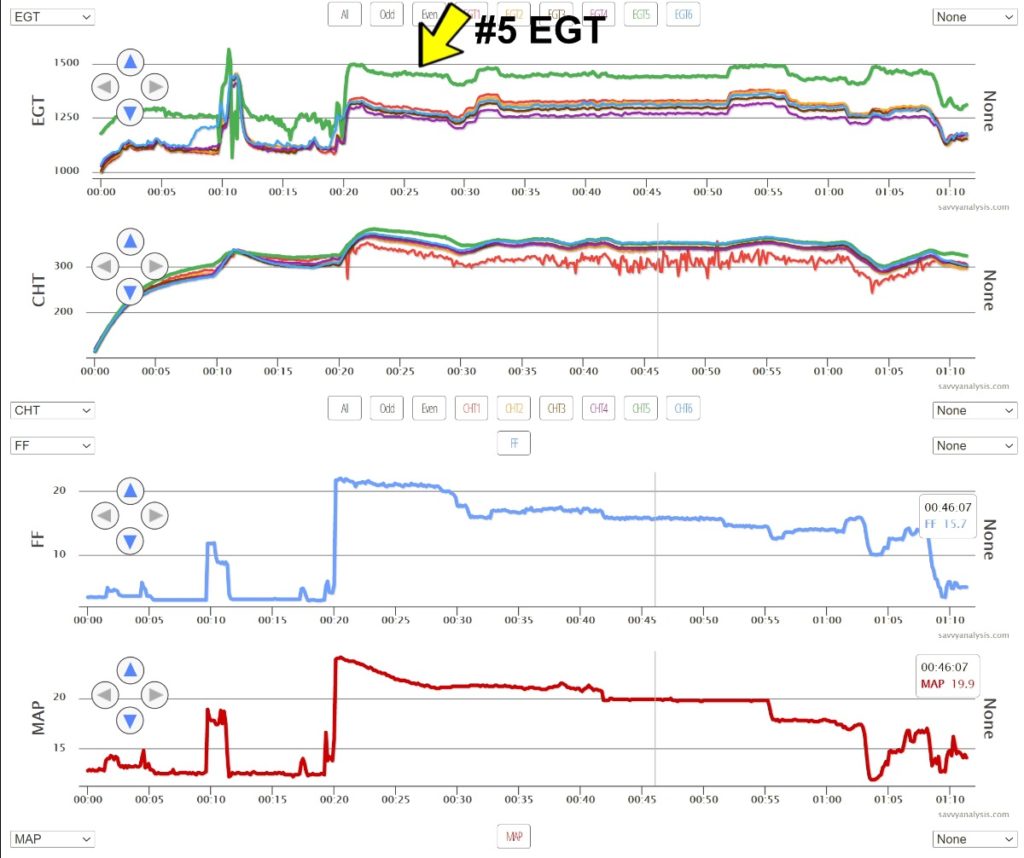

A week passed, then Mark opened a new SavvyAnalysis Pro ticket and asked Joe to take a look at the most recent flight of the Trinidad:

“That #5 cylinder definitely has problems,” Joe told Mark. “I really think it’s more than just a bad spark plug. You might want to replace both plugs on general principles, perhaps they sustained hidden damage during the detonation event. But I also think you need to check for a damaged fuel nozzle, an induction leak, and the valve train. If none of those reveal the cause, you might be wise to remove the cylinder.”

“We at Savvy really hate to see our clients pulling cylinders unless there’s no alternative,” Joe continued, “but I really don’t have a good feeling about a cylinder that spent so much time so far over redline CHT.”

“And by the way,” Joe added, “you might want to look at your #1 CHT probe, it’s starting to get awfully noisy.”

About a week later, Mark uploaded the data for another flight—marked “test flight”—that revealed the high #5 EGT problem completely resolved. Joe never did find out exactly what remedial action was taken to solve the problem, and after working on a problem like this it’s frustrating not to hear the punch line.

Oh, and by the way, Mark is still uploading data more than two years later. His #5 EGT still looks perfect, but the #1 CHT probe is still noisy!

Punch line or not, Mark’s case illustrates the value of how engine monitor data in the hands of a trained analyst is so useful in obtaining a forensic reconstruction of an abnormal event, helping to isolate the fault, and determining whether follow-on maintenance actions were successful in resolving the issue.

A subscription to SavvyAnalysis Pro costs just $129/year for a single-engine airplane like Mark’s Trinidad, and entitles you to unlimited analyses by Joe and his team of Savvy analysts. It also provides you with regular Savvy Report Cards, Trend Analyses, and FEVA risk assessments that warn you of potential exhaust valve issues.

At less than the cost of a tank of 100LL, we think it’s a heck of a bargain. What do you think?

Learn more about SavvyAnalysis.

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: