These two key measurements can tell us a lot about what’s going on inside our cylinders.

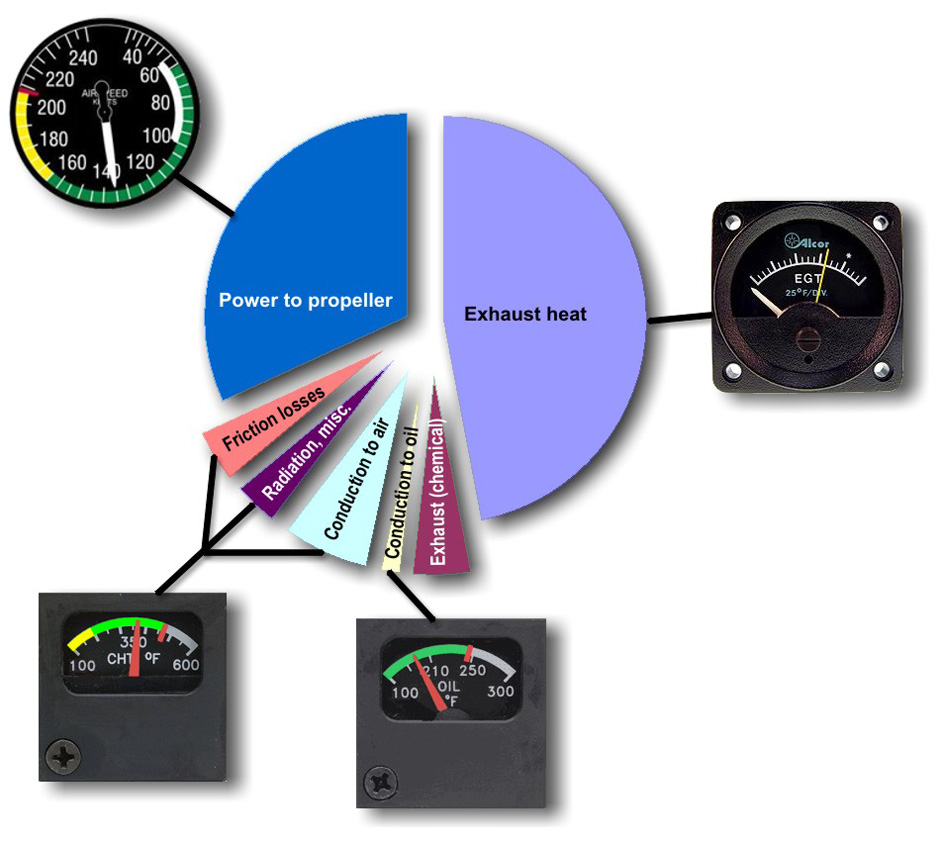

My column last month talked about the fact that our piston aircraft engines convert only about one-third of the energy contained in avgas into useful energy to the propeller. About half the fuel’s energy goes out the exhaust pipe, while the remaining one-sixth is transferred to the cooling air that passes over the cylinder fins and through the oil cooler.

The wasted energy is measured and displayed on a triad of cockpit gauges: oil tempera-ture, cylinder head temperature, and exhaust gas temperature. The one-third that actually makes it to the propeller is reflected on another cockpit instrument: the airspeed indicator.

CHT vs. EGT

From a powerplant management perspective, it’s crucial to understand that CHT and EGT tell us quite different things about what’s going on inside the engine. CHT mainly reflects what’s going on in the cylinder during the Otto cycle power stroke before the exhaust valve opens, while EGT mainly reflects what’s going on during the exhaust stroke after the exhaust valve opens:

- CHT measures heat energy wasted during the power stroke, when the cylinder is under maximum stress from high internal pressures and temperatures.

- EGT measures heat energy wasted during the exhaust stroke, when the cylinder is under relatively low stress.

High CHTs generally indicate that the engine is under excessive stress for its own good. That’s why it’s so important to manage the powerplant in a fashion that limits CHTs to a tolerable value. For Bonanzas and Barons, a reasonable rule-of-thumb is that optimum engine longevity is achieved by limiting CHTs to 380°F. CHTs above 400°F should be considered abusive, and grounds for “doing something right now” to bring them down.

By contrast, high EGTs do not indicate that the engine is under excessive stress. They simply indicate that a lot of energy from the fuel is being wasted out the exhaust pipe rather than being extracted in the form of mechanical energy sent to the propeller. High EGTs do not represent a threat to engine longevity. The engine is simply not capable of producing EGTs that are high enough to harm anything. Therefore, attempting to limit EGTs in an attempt to be kind to the engine is simply wrongheaded.

- Limiting CHTs is essential to ensure cylinder longevity.

- Limiting EGTs accomplishes nothing useful.

One caveat: Turbocharged engines usually have a turbine inlet temperature (TIT) red line that should be observed, particularly when flying at Flight Level altitudes. The purpose of the TIT limit is to protect the fast-spinning turbine wheel from blade stretch. The TIT limit is usually either 1650°F or 1750°F, depending on the model of turbocharger in-stalled.

Things that affect CHT

It’s obvious that CHT increases when power is increased, and that it also increases when cooling airflow is decreased. But there are a number of other factors that also affect CHT.

Recall that during the Otto cycle power stroke, peak internal cylinder pressure and temperature optimally occur at 15° to 20° of crankshaft rotation after top dead center – a point denoted by θpp. Anything that causes θpp to occur earlier (i.e., closer to TDC) in-creases CHT, and anything that causes θpp to occur later (further from TDC) decreases CHT.

For example, advancing the ignition timing so that the spark plug fires earlier causes θpp to occur earlier and increases CHT. Retarding the ignition timing so that the spark plug fires later causes θpp to occur later and decreases CHT.

Alternatively, changing the mixture can affect CHT by changing the rate at which the air-fuel charge burns, and therefore causing θpp to occur earlier or later. The burn rate of the air-fuel charge is fastest a mixture that is slightly richer than stoichiometric, approximately 50°F rich of peak EGT (50°F ROP). Either richening or leaning the mixture from that point decreases the burn rate, causes θpp to occur later, and consequently reduces CHT.

Failure of one spark plug or magneto can also affect CHT, because the air-fuel mixture takes longer to burn when it is ignited by only one spark plug instead of two. This causes θpp to occur later and CHT to decrease.

Things that affect EGT

EGT is affected by mixture. Peak EGT occurs at approximately the “stoichiometric” (chemically correct) mixture of 14.7 pounds of air for each pound of fuel, at which there is exactly the right amount of oxygen to oxidize all the hydrocarbon chains in the fuel. Leaner mixtures cause EGT to decrease simply because less fuel produces less energy. Richer mixtures also cause EGT to decrease because excess (unoxidized) fuel absorbs heat energy when it vaporizes. Consequently, peak EGT can be used to identify a stoichiometric mixture, and decreases in EGT from peak can be used to establish mixtures richer or leaner than stoichiometric (ROP and LOP).

Important: The absolute value of EGT is not important. It is quite common for different cylinders of the same engine to indicate quite different EGTs, and that’s perfectly normal. What’s important is the relative value of EGT for a particular cylinder compared to that cylinder’s peak EGT value. In other words, we really don’t care whether a cylinder’s EGT is 1390°F or 1460°F – what we care about is whether the cylinder’s EGT is 80°F ROP or 30°F LOP.

EGT is also affected by ignition performance. Advanced ignition timing that ignites the air-fuel charge earlier and causes θpp to occur earlier decreases EGT. Retarded ignition timing that ignites the air-fuel charger later and causes θpp to occur later increases EGT. Failure of one spark plug or magneto causes the air-fuel charge to take longer to burn, so it causes θpp to occur later and EGT to increase. (You can see this EGT rise every time you do a pre-flight mag check.)

Finally, a burned exhaust valve can increase EGT if it allows some of the ultra-hot gas during peak-temperature phase of the power stroke to leak past the valve and impinge on the EGT sensor probe located a few inches beyond the cylinder’s exhaust port. Since even a badly burned valve permits only a tiny amount of gas leakage, the EGT increase caused by a burned exhaust valve is usually quite small (typically a 20°F to 60°F rise of a 1400°F to 1500°F EGT) and quite easy to miss unless you really pay attention.

Powerplant management using CHT and EGT

When adjusting power settings and mixture, CHT is the most important reference measurement, because CHT is the best proxy we have in the cockpit for internal cylinder pressure (ICP) which represents stress on the engine. You should establish a target CHT that represents the maximum stress you want to place on your engine – 380°F works well for most Bonanzas and Barons under typical conditions – and then adjust your power settings, mixture, and (if applicable) cowl flaps to ensure that all cylinders are operating at or below that target.

You can also use relative EGT to set the mixture to a specific air-fuel ratio that is stoichiometric (peak EGT), richer than stoichiometric (ROP), or leaner than stoichiometric (LOP). For example, best power mixture is generally about 100°F RP, while best economy mixture is generally 20°F to 50°F LOP.

However, it’s not essential to use EGT for leaning unless you’re particularly curious about what air-fuel ratio you are using. As long as CHT is does not exceed the desired target, whatever mixture you have set is fine. I very seldom refer to EGT when I lean my engines; I use fuel flow to get somewhere in the ballpark, and then fine-tune by reference to CHT.

You obviously need an engine monitor to measure the CHT of all six cylinders (or twelve if you fly a twin). If all you have is the factory CHT gauge, then all you know is the CHT of one cylinder (and only very approximately at that) – you have no idea how hot the other five are running. This is one reason why I consider an engine monitor to be required equipment in any airplane I fly – and you should, too.

Troubleshooting using CHT and EGT

Having an engine monitor that displays and records CHT and EGT for each cylinder is also absolutely invaluable for detecting and diagnosing a wide variety of engine problems. The art of troubleshooting with an engine monitor is a subject that’s so rich and fascinating that I’m in the process of writing a book about it. But to make a very long story short, here’s a list of common engine problems and how they show up in CHT and EGT:

- Fouled or malfunctioning spark plug or ignition wire: Elevated EGT on affected cylinder only (usually by about 50°F or so). Slightly reduced CHT on affected cylinder. Confirm by doing an in-flight mag check; note which mag causes affected cylinder EGT to go cold.

- Malfunctioning magneto: Elevated EGT on all cylinders (usually about 50°F or so). Slightly reduced CHT on all cylinders. Consider confirming by doing an in-flight mag check, but be careful – if you turn off a mag and the engine quits, pull the mixture control before turning the mag back on to avoid possible afterfire-damage to the exhaust system.

- Partially clogged fuel injector: If ROP mixture, elevated EGT and CHT on affected cylinder. If LOP mixture, reduced EGT and CHT on affected cylinder, and possible engine roughness.

- Completely clogged fuel injector: Engine rough, EGT cold, CHT dropping. Attempt to unclog by going to full-rich mixture and high boost; otherwise, land as soon as practicable.

- Burned exhaust valve: Slightly elevated EGT on affected cylinder only (usually by about 20°F to 60°F, depending on how badly the valve is burned). EGT usually varies between normal and slightly elevated, often (but not always) in a rhythmic fashion with a frequency of roughly one or two cycles per minute. (If burned valve fails completely, EGT of affected cylinder will go cold and engine will run rough.)

Abnormal combustion events

CHT and EGT may also be used to detect abnormal combustion events, including detonation and pre-ignition. These will be the subject of another article. Stay tuned!