Shakespeare loved a good pun. Even he might groan at this one. I wanted to write about magnetos and I recently saw “Hamnet” and you know the rest. Usually the format of the Puzzler is I present a scenario and we work through the decision tree to figure out what caused it. This one’s a little different – they’re all mag problems. So now that you know the answer these should be easy, right? If, as the Bard would say, “good luck would have it”, you’ll discover your mag issue in your pre-flight runup and put the horse back in the barn.

If you get roughness in the air and a quick glance at the engine data monitor tells you it’s happening across multiple cylinders – maybe all of them – the remedy is to switch to the good mag and restore smooth running. Left or Right, that is the question. You’ve got a 50/50 chance. Can the engine monitor help improve those odds? That’s what we’ll look at this month, using data from a Cirrus SR22TN, a Cessna Turbo 210, and a Glasair Sportsman.

If you need a refresher on mags, here are three Mike Busch webinars on Savvy’s You Tube channel. How Mags Work, How Mags Fail, and All About Magnetos. Here are the articles if you’d rather read. How Mags Work, How Mags Fail, The Mag Check.

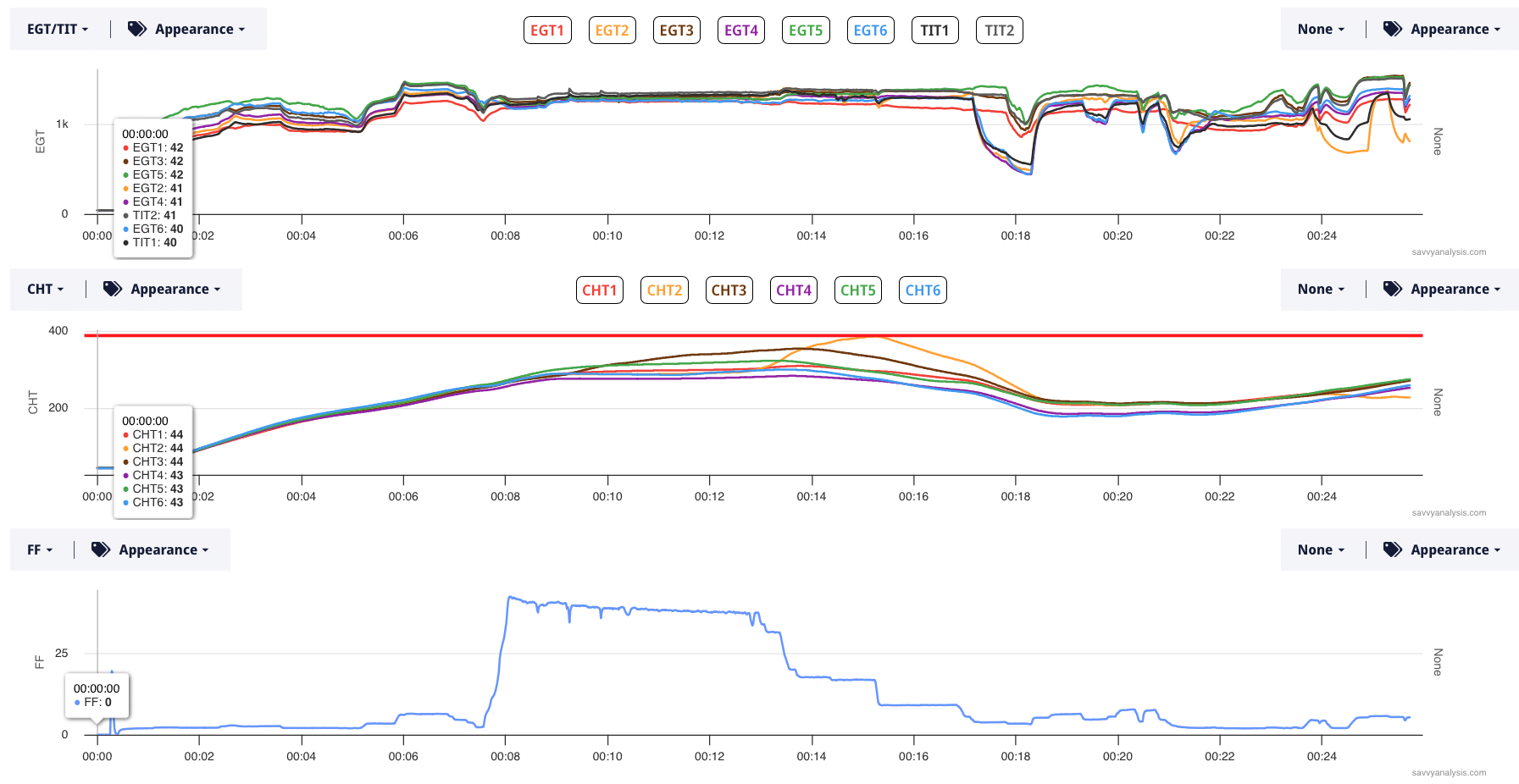

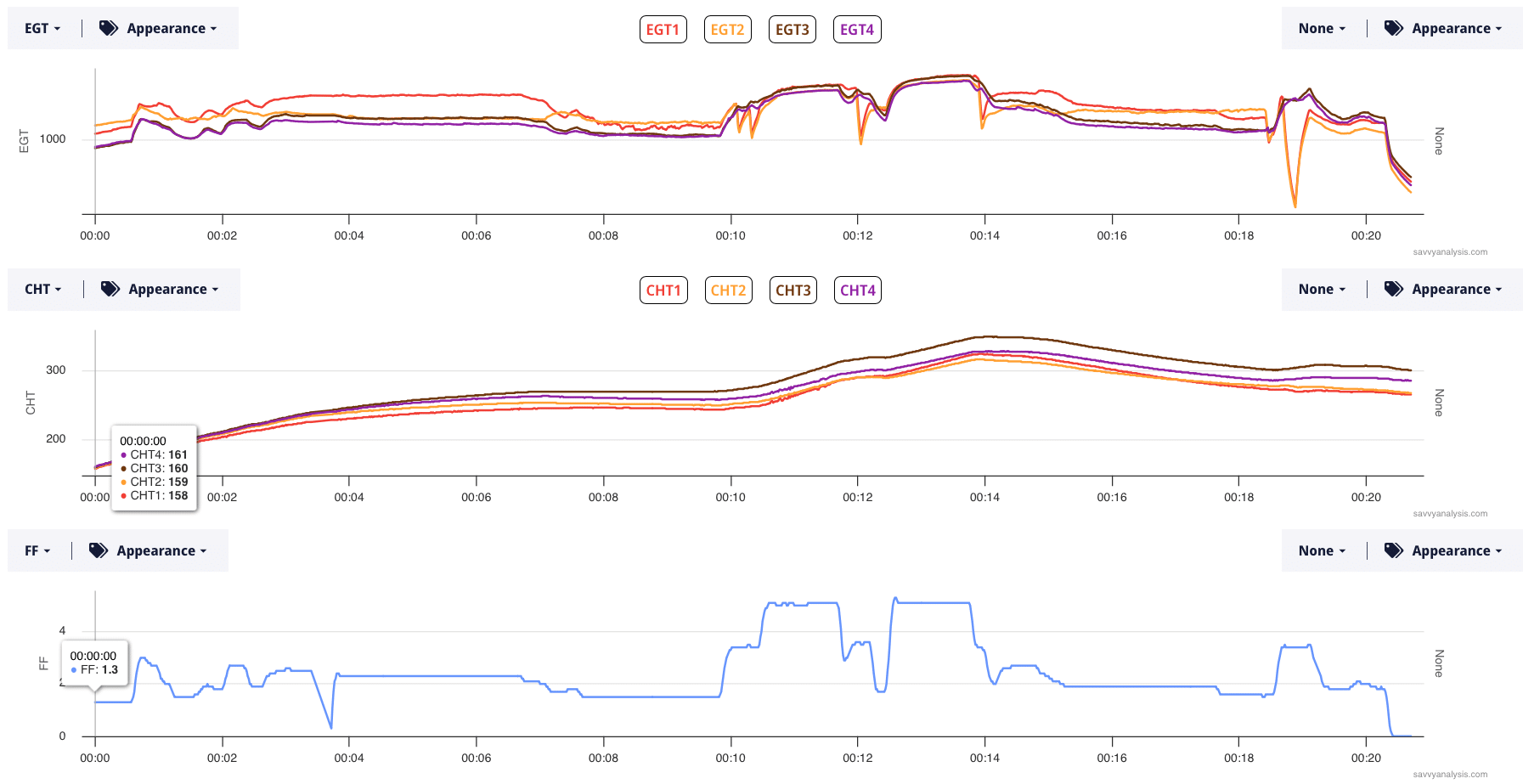

First up is a turbo-normalized Cirrus SR22 powered by a Continental IO-550-TN with data from a Garmin G1000 with a one second sample rate. Here’s the 26 minute flight with the cursor out of the way on the left. EGTs, CHTs and FF.

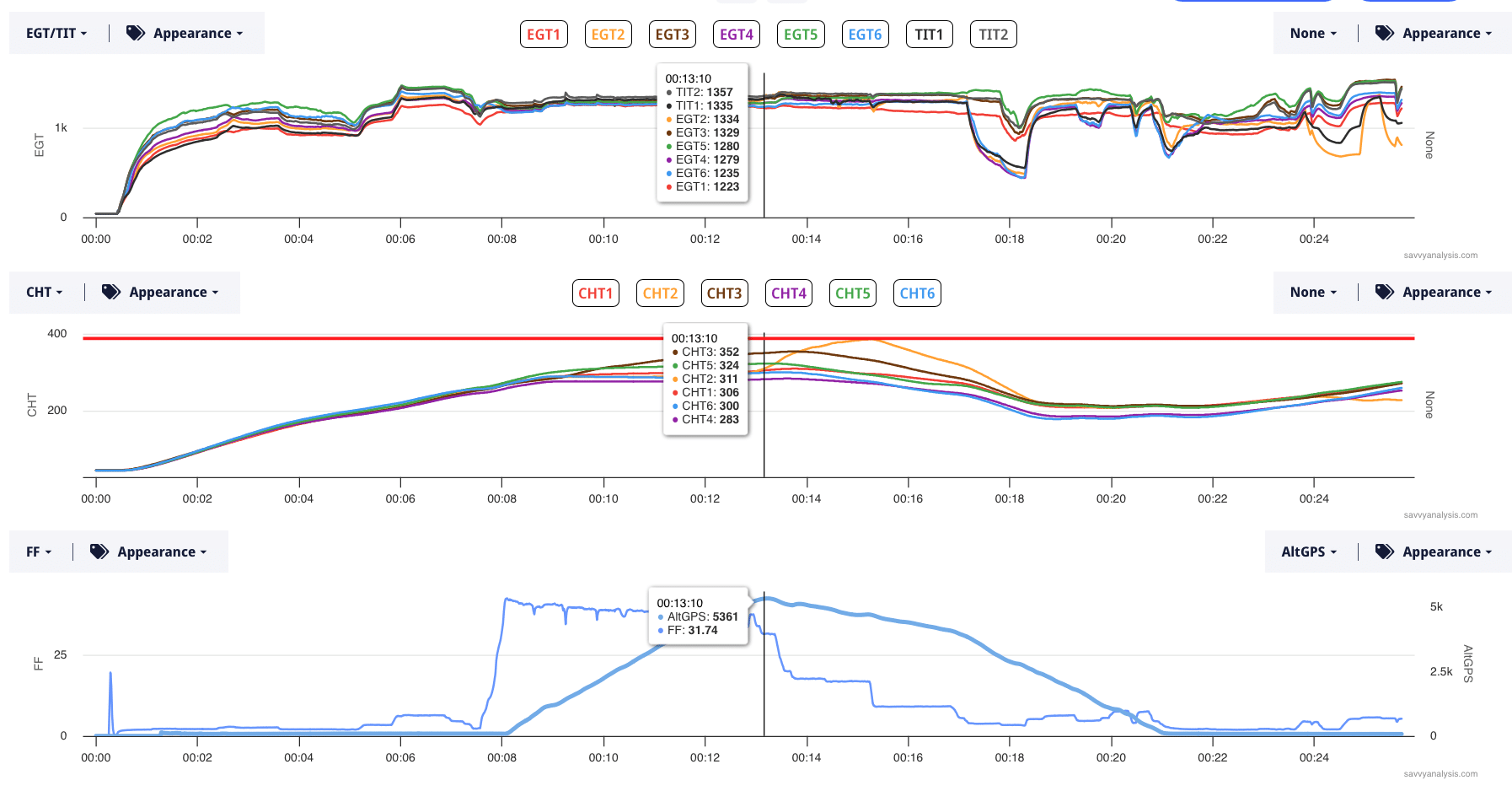

The mag clearly fails at the 17 minute mark, but the engine roughness began earlier. For context, here’s the same data with GPS ALT added in the 3rd rank.

The flight map – which I can’t show in the interest of privacy – confirms that 13:10 is where the pilot turns back for the airport. Let’s isolate EGTs and look for signs of impending mag failure. Cursor is back to the left out of the way. The vertical line is the turn-back at 13:10.

Something else happens at 13:10. CHT 2 begins an excursion and EGT 2 rises then becomes erratic, which together are symptoms of a detonation event. It’s hard to see the EGT 2 jumpiness in the first screenshot – easier to see when zoomed in. Does the detonation event cause the mag to fail 4 minutes later? We don’t think so. But the increasingly weak spark from the R mag may have triggered the detonation event.

GPS ALT shows that landing is at 21 minutes. So when the mag fails at 17 minutes, the pilot has already reduced to idle, with FF at 5 GPH on its way to 3 GPH. Let’s address flight safety by trying to answer three questions.

1 – Does the engine data offer any clues about the impending mag failure? We’re not seeing it. The pre-flight mag check looks normal – no spikes or wobbles – and takeoff EGTs look normal. Initial cruise looks normal. EGTs start diverging at around the 10 minute mark, and 3 minutes later the roughness is bad enough for the pilot to turn back.

2 – When the mag fails, could the pilot have restored a smooth engine by switching to one mag? This may not be the best flight to answer that question because by then the pilot just wants to get back on the ground and the engine’s basically idling as he glides to the runway. But theoretically that answer is yes.

Depending on how the mag fails, you should expect to see a rise in all EGTs – just as you do when you ground a mag in your pre-flight mag check – and will probably see a drop in the CHTs of the cylinders whose bottom plugs just stopped firing. In this case that’s 2-4-6. But the CHT drop takes time to evolve and once you’re past the startle factor of a failed mag in flight you probably don’t want to wait around for a CHT drop to register before you make your next move. And we don’t have enough case studies of mags failing in flight to give you an always-do or never-do solution. We’re working on it.

3 – Given that, which mag should the pilot have switched to? We know from post-flight maintenance that the nylon gear on the right mag failed. So it didn’t fail completely. And it didn’t fail from old age. It failed about 200 hours after overhaul. So not infant mortality and not too much time in service. Right in the middle of its service life where you’d think it would be most reliable. EGTs on the left side of the engine, 2-4-6, drop significantly lower than 1-3-5 when the right mag fails, as does TIT1 for the turbo on that side. The right mag fires the bottom plugs of 2-4-6.

The goal after a mag failure is to switch to the good mag. If you switch to the bad mag you’ve probably made things worse. And could potentially make things worse still. If the engine quits or sputters, fight the instinct to switch back to both until you have reduced power. If you have unburned gas that ignites in the exhaust system you could do a lot of damage. Your survival instinct will want to get that switch to BOTH or the other mag you didn’t choose, but take a beat and reduce power first. Don’t make a bad situation worse.

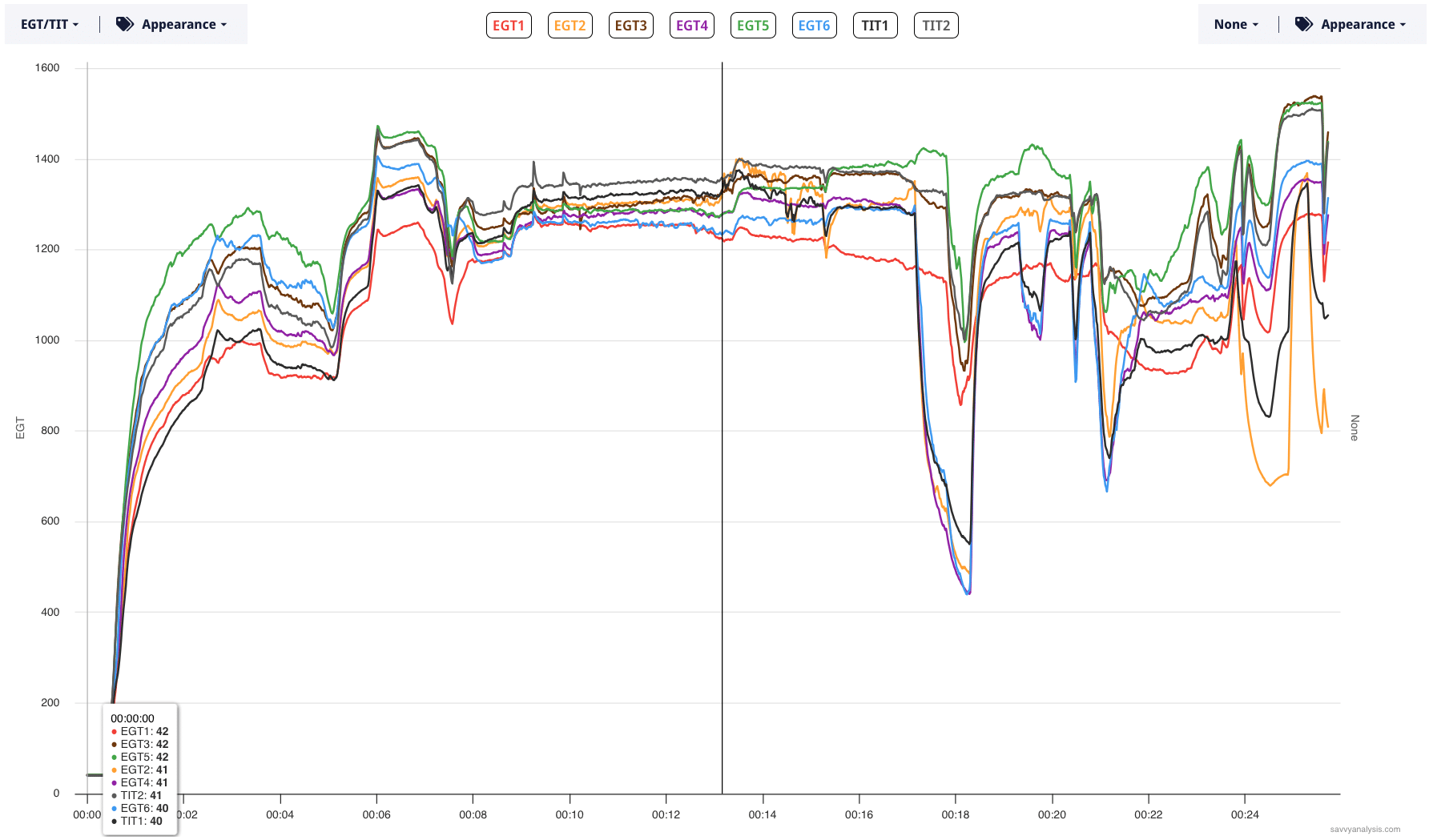

Next is a Cessna Turbo 210 powered by a Continental TSIO-520 with data from an EI MVP-50P with a one second sample rate. This plane was making its was across the US and encountering roughness in cruise, and in the pre-flight mag checks the right mag was rougher than the left. EGTs, CHTs and FF.

CHTs and FF look ok. The purple EGT 4 trace has to be a failed probe, because the initial values at 00:00 in the timeline are below zero. That’s the giveaway. Any combustion anomaly you can think of still gives us non-negative numbers. EGT 3 in the 450º range is not so easy to dismiss. It’s steady but very low. We recommended checking the plugs and harnesses and that revealed the wire for the bottom plug of cyl 3 was arcing on the valve cover.

But wait, there’s more! Fixing that brought EGT 3 back into the fold, but there was still roughness on the right mag. Logbook review determined that the mags were overhauled 1500 hours ago along with the engine overhaul, but the last inspection was 700 hours ago. Roughness went away after both mags were IRANned.

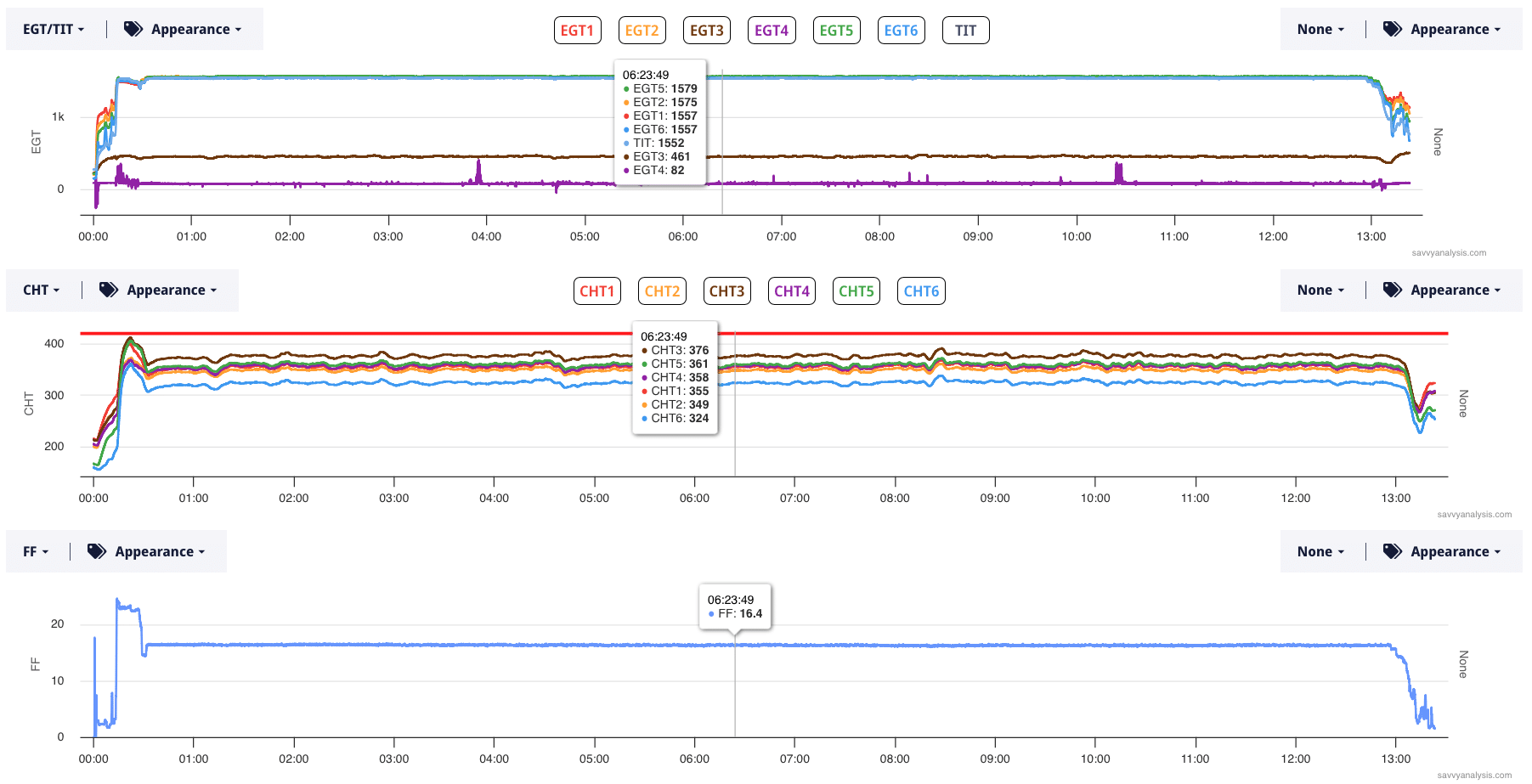

Next is a Glasair Sportsman powered by a Lycoming IO-390 with data from an Advanced Flight Systems 5600 with a one second sample rate. I have had two mechanical failures — a flap cable and a mixture cable — recently in my Bellanca Viking and both happened on the ramp in front of my hangar. I’m convinced that’s the best place for stuff to fail. The run-up area is a close second. This is data from a run up.

The Cirrus and the Cessna in the cases above are standard “tractor” mags. This Glasair uses two Pmags, and they’re wired differently than the traditional “tops of the same side and bottoms of the other side” configuration. The data shows that EGTs 1 and 2 are misbehaving but 3 and 4 look normal. Fortunately the troubleshooting guide helped connect the dots.

Wasted spark systems fire plugs IN PAIRS (front pair and then the rear pair). If you can associate a symptom (cold cylinder or EGT dips) with a single (1) cylinder , the cause is not likely to be inside the ignition box itself. It may be in the plug wire, the plug, the cylinder, or fuel to that cylinder – i.e. downstream from the ignition head.

Alternatively, if you detect a pattern that affects two (opposing/paired) cylinders simultaneously (cylinders 1 & 2, or 3 & 4), then the issue is likely to be the ignition control head or the ignition coil.