Can you tell I made a New Year’s resolution to kick my vocabulary up a notch? Perspicacious is a hard word to work into conversation but it pretty accurately describes a Puzzler reader. I like this definition — showing an ability to notice and understand things that are difficult or not obvious. Yep, that’s how we roll. And it’s January, so it’s time to restate the mission of these monthly Puzzlers. The goal is to help pilots recognize data anomalies in real time to make good decisions about the safety of the flight, and help owners to make informed maintenance decisions. There’s a third goal – to help you the reader develop your perspicacity – your ability to recognize and understand engine data anomalies and borescope pictures. So let’s get started.

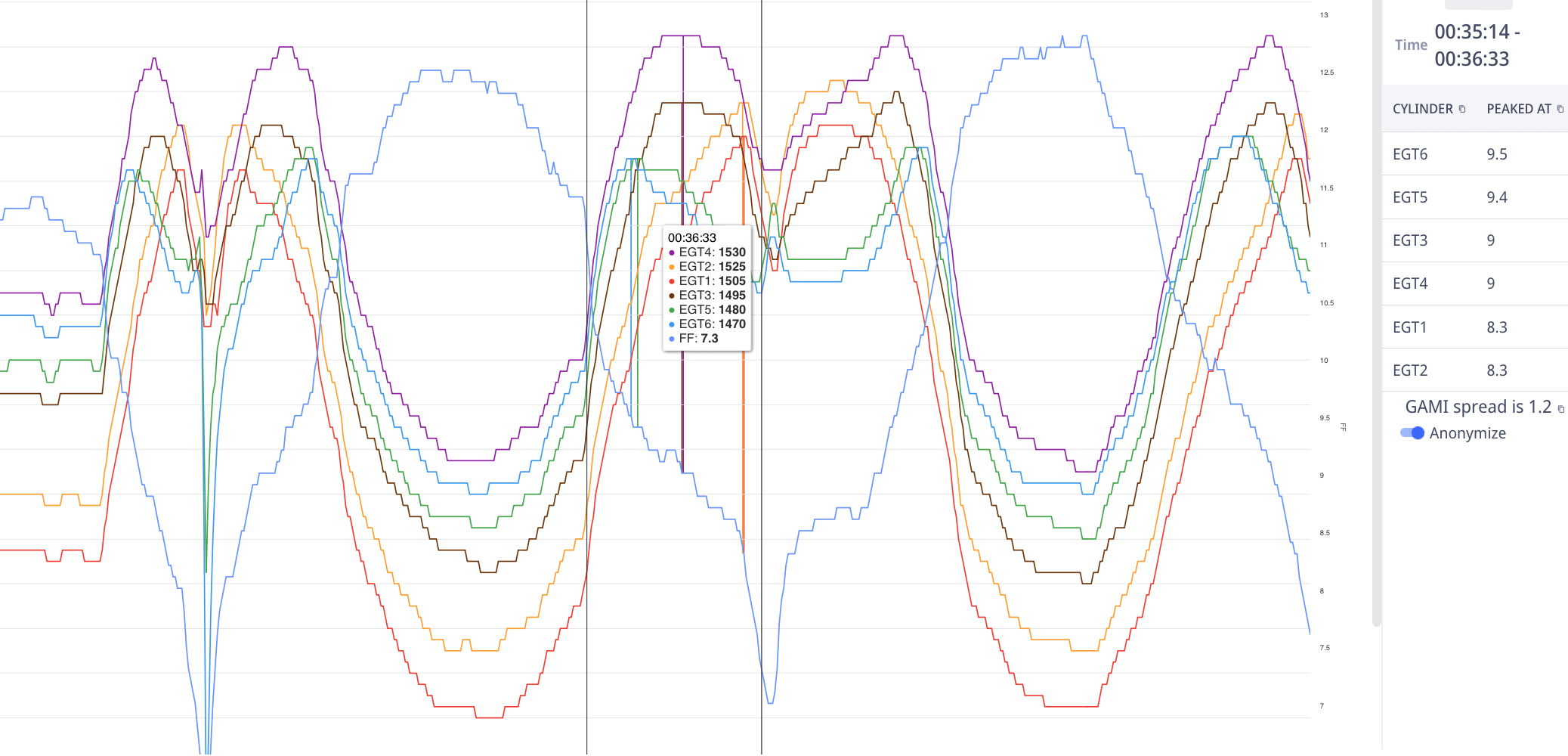

First up is a Piper Turbo Arrow IV powered by a Continental TSIO-360 with data from a Garmin G3X with a one second sample rate. This is a set of mixture — aka GAMI — sweeps after our client reported rough running in cruise and inability to get FF low enough to run LOP in cruise.

The objective of GAMIjectors or Continental position-tuned injectors is to get each cylinder to peak at the same FF, resulting in a spread of 0.5 GPH or less. In this case, we have three pairs. They happen to be paired from the front of the engine to the back of the engine. (5 and 6 are in the front on Continentals.) We don’t know if that’s coincidence or a contributing factor to the MIF (maintenance-induced failure). In a scenario where positioned-tuned injectors got placed into the wrong cylinders you’d expect to see more random results than these three pairs. But that’s what happened. Once the injectors were matched with the correct cylinders the airplane could run LOP in cruise again.

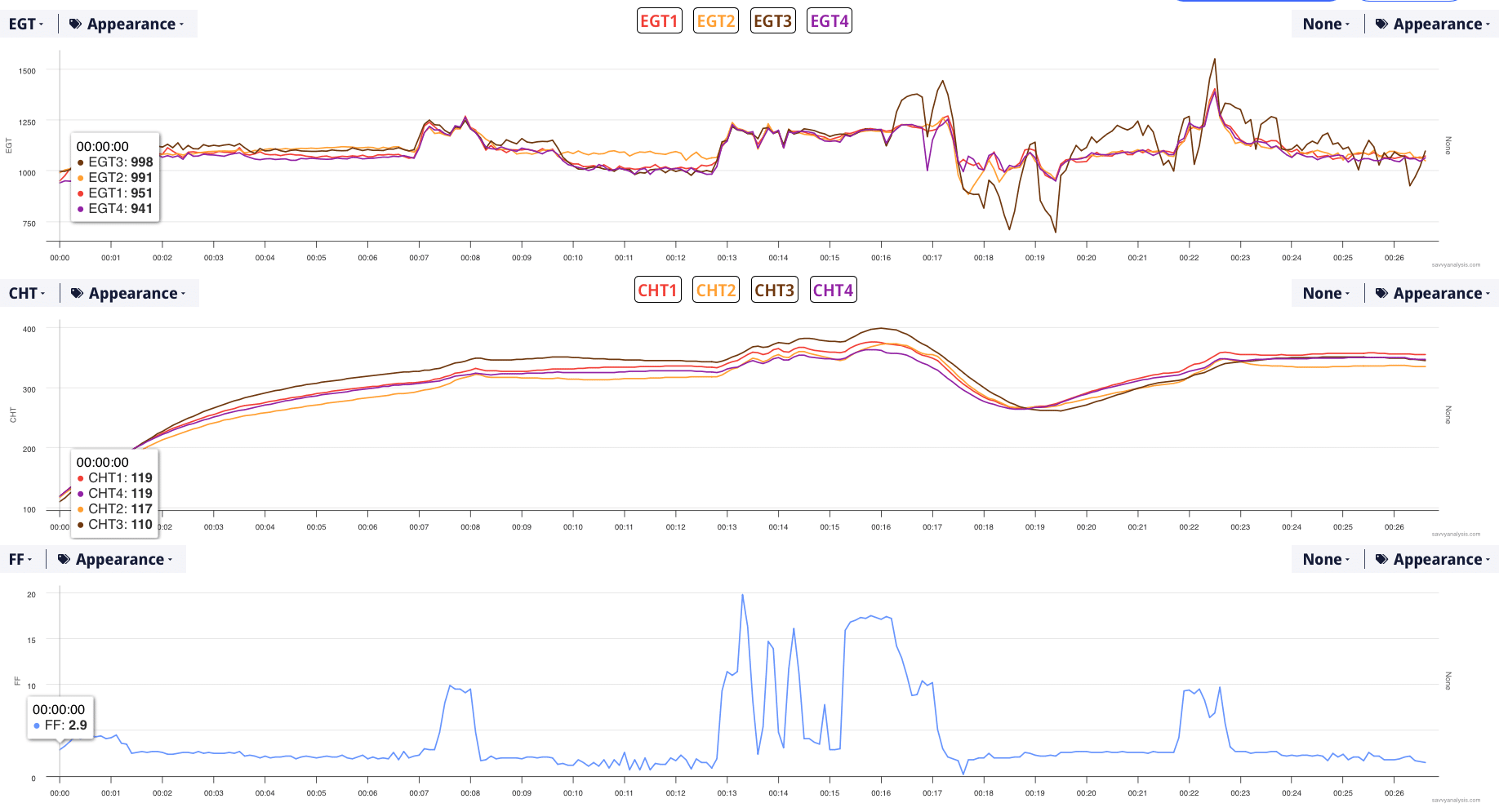

Next is an RV 4 powered by a Lycoming IO-360 and data from a JPI 350 with a 1 second sample rate. Cursor is off to the left to keep it out of the way. This is one trip around the pattern beginning at the 13 minute mark.

Rather than summarize the symptom, here it is in our client’s words —

I have been experiencing random power losses that present like water in the fuel. After a brief 2 second power loss the engine runs perfectly normal. No evidence of water has ever been found in drain samples. These power losses are completely random and can happen on takeoff, climb or cruise although most of them are during climbout. On my last flight i had 2 power losses in the space of one 5 minute flight around the pattern.

So those FF spikes between 13 and 15 minutes are not pilot induced. That’s the engine jumping from making power to trying to quit. It smooths out at about the 15 minute mark. Then we got this update —

Upon inspection they found 2 damaged spark plugs and pitting in No. 3 cylinder. (Note all damage occurred on that one 5 minute flight as I had borescoped it prior to that flight and besides a closed up plug everything looked pretty normal). The engine was overhauled about 250 hrs ago and that shop is adamant that it’s crossfiring from bad mags – so I sent them off for bench testing and overhaul. No problems were found with the mags.

Did anyone ever tell you that had a screw loose? We got this update —

A loose screw was just found in the intake manifold.

So we had a debate amongst ourselves whether a screw could make its way from outside the engine into the intake manifold then into a cylinder and back out again. It’s a pretty good bar bet because the conventional wisdom is that once the screw got past the intake valve it would either stay in the barrel or be thrust out past the exhaust valve and into the big sky. The magic screw theory seemed impossible to some of us, until you remember what a dynamic environment a cylinder is in with a crank turning at 2700 RPMs. It turns out that a couple of our teammates had seen it before. And one was from a loose plenum on an RV. Here’s the loose screw and some of the havoc it wreaked.

And here’s the rub. The loose screw wasn’t causing the engine to quit. The power loss was caused by a loose fuel line that was allowing air to be sucked into the fuel line. So then the question was why didn’t the line just stay broken and cause fuel starvation until it was fixed? Why did it work most of the time and then chop the fuel randomly? Our best answer is heat, with an assist to angle of attack and bank angles. As things heated and cooled, and when you factor in G forces from climbs and turns, the opportunities for leaks waxed and waned.

Next is a Cessna 182 powered by a Texas Skyways O-550 with one Surefly and one tractor mag, and data from a Garmin G3X with a one second sample rate. Here are EGTs, CHTs and FF from two recent flights.

Second flight —

The concern is cylinder 2. Is it bad data or is it an engine problem? Notice the spikes in EGT 2 at engine start. That’s one tick in favor of bad data. Our client didn’t report roughness or a perceptible change in power as EGT 2 dances around. That’s two ticks for bad data. But what about CHT 2 being a little on the high side in initial climb then moving lower and staying lower until landing? It would be nice to have a baseline flight where EGT 2 wasn’t dancing around to see if CHT 2 was lower there, too. Here’s that baseline flight from about 2 months earlier.

As suspected, CHT 2 ran lower before EGT 2 started making a fuss. That’s three ticks for bad data. The pattern evolved from shorter cyclical changes to bigger jumps. It always makes sense to check the connection first but this one looks like a failing probe.

We’ll finish this month with a Beech 24 Sierra powered by a Lycoming IO-360 and data from a Garmin G3X with a one second sample rate. Here are EGTs, CHTs and FF from a recent flight. Nothing special about cursor placement – it’s on the first takeoff of the flight.

If you look closely, you can see a zipper-looking pattern in EGT 3 starting at about the 45 minute mark and continuing on through that cruise segment at 55 minutes. Let’s zoom in for a closer look. EGT 3 is in bold.