Maybe it’s just a coincidence that we use the same word for a piece of silicone that directs cooling air over an aircraft engine – and a state of bewilderment. In the world of sound it’s also used to describe the box that contains a speaker. Maybe it’s just cruel irony at work. As the Danish humorist Victor Borge used to say “It’s your language. I’m just using it.”

I’m writing this on the weekend before AirVenture 2020 was scheduled to start. Normally I’d be making my way there – the last few times in the right seat of Mike Busch’s 310. I’m glad EAA set up so many online events for the week and a little taste of the comeraderie of Oshkosh is better than no taste, but let’s hope next year is more like last year.

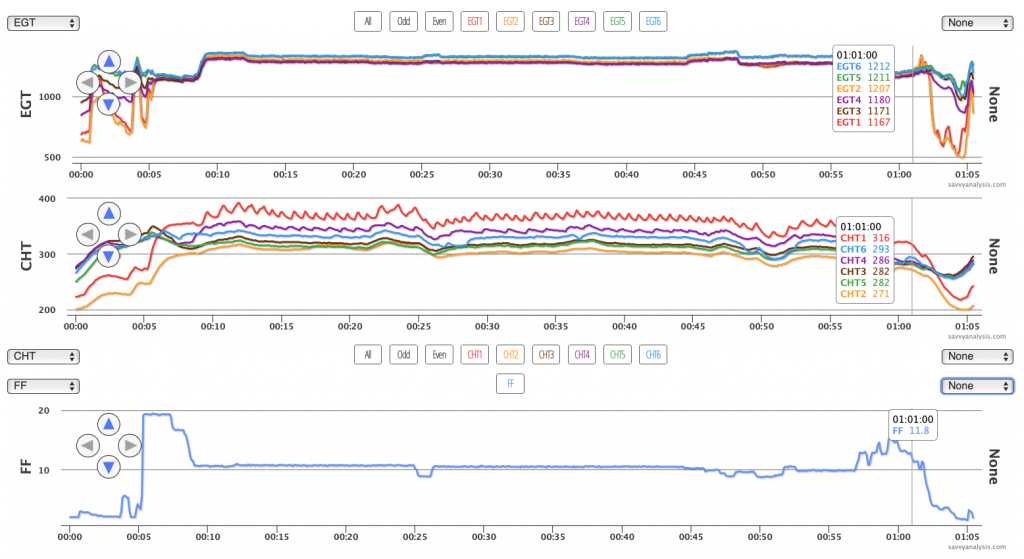

Let’s start this month with data from a Cessna 172 XP powered by a Continental IO-360 engine and data from a JPI 830 with a 6 sec sample rate. Those are the particulars but the fact is we see this pattern with big bore 6s and smaller 4s – turbos and air breathers, singles and twins. First the “establishing shot” of the full flight with EGTs on top, then CHTs and FF below.

Let’s zero in on the trouble and discard the distractions. EGTs are fine – nothing to indicate the trouble we’re seeing with CHTs is related to irregular combustion. FF is also ok. And the patterns in CHTs are confined to 1 – the red trace, and 4 – the purple trace. Within those traces, they’re steady during ground ops and the patterns happen in flight. The puzzler is – what’s causing this?

If the baffle is loose, or at least loose enough to move with the increased airflow of climb and cruise, it would make sense for the CHT to increase and stay there. What’s causing the shark tooth pattern? The repetitive oscillation up and down? There’s your clue.

Do you use the autopilot when you fly? Probably – most pilots do. I’ll admit the first time we saw patterns like this in CHTs we were, uh – puzzled. But if you think about the job Otto (or George or whatever you call yours) does, it’s to make small adjustments in angle of attack in order to maintain a steady altitude. If your baffles are tight, they don’t respond to those changes in angle of attack. If your baffles are loose, they probably repositioned as soon as the incoming air hit them, so your CHT is probably high but steady. If your baffles are in-between, they’re loose enough to respond to changes in angle of attack.

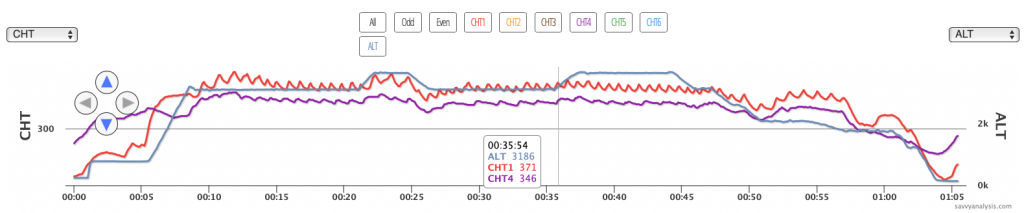

Here’s the same flight with CHTs 1 and 4 isolated and ALT overlaid.

The pattern in CHT 1 starts just before the 10 min mark when the nose goes over and the autopilot comes on. (Otto on/off isn’t logged but we asked the client to verify.) ALT is steady because the nose is oscillating slowly. It’s about 40 seconds from peak to peak, so 20 up / 20 down – probably too slow to perceive in the cockpit.

Notice the pattern change at the 21 min mark when the ALT shows a climb, then it resumes the previous pattern 5 mins later after the descent. Why don’t we see that again during the subsequent climb at 37 mins? We don’t know. If you have a theory on that, please post a comment.

So far, every time we’ve seen this pattern and asked “did you use the autopilot for the cruise segment of this flight?” we’ve gotten “yes” for an answer. So that’s our usual suspect until proven innocent.

I can’t let this opportunity pass without a word about baffle looseness. Sometimes when we see this pattern and recommend checking the baffles, clients will report that they or their A&P took a look and everything looked fine. That’s not surprising if you consider it took 100 or more knots of wind to get the baffle to move. So it might take a good blast of shop air to replicate the problem on the ground.

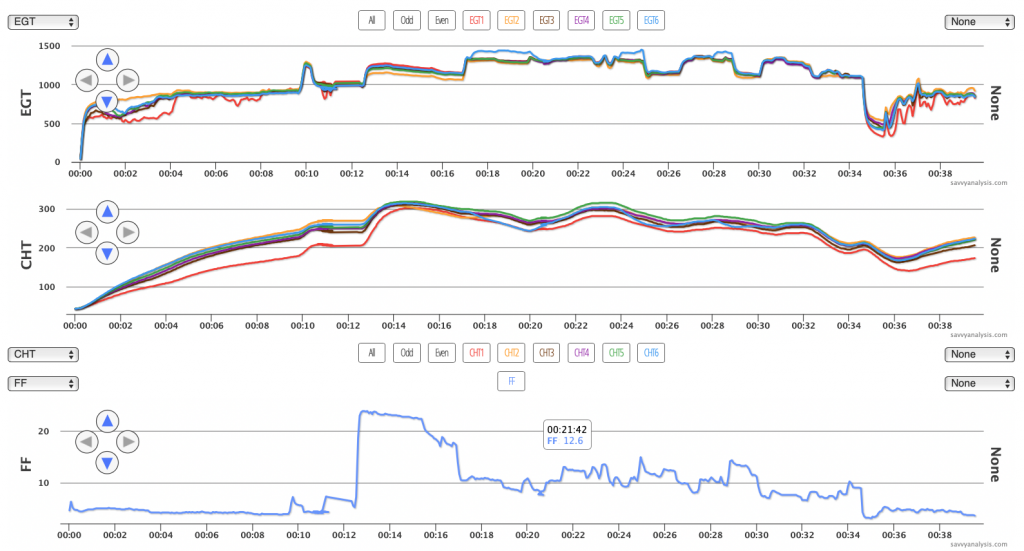

Next up is data from an RV-10 with an Aero Sport Power IO-540 and data from an Advanced Flight Systems 5600 with a 1 sec sample rate. EGTs, CHTs and FF. This engine uses the Silverhawk fuel injection system and a Lightspeed electronic ignition. Not saying that’s a clue – but not saying it’s not.

The issues here are EGTs and CHTs for cyls 1 and 6. EGT 1 is erratic and low during taxi-out, corroborated by CHT 1 being low. EGT 6 is ok during taxi-out, takeoff and climb, then rises when FF is leaned – pretty much every time FF hits that 10 GPH line. Both anomalies look like spark issues, so we asked for a LOP mag check.

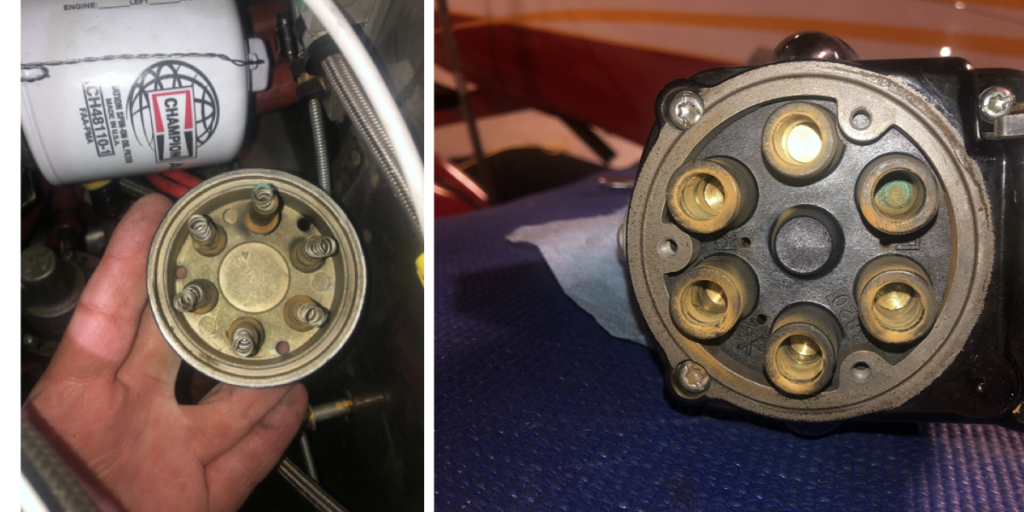

The big drops in EGT 6 are from the standard mag, not the Lightspeed. Examination of that fine-wire plug confirmed a lot of soot and carbon fouling, but it wasn’t oily. The harness looked ok, so attention focused on the mags, which had 1300 hours in service. Once the mag was cracked open for inspection it didn’t take long to see why spark had been so poor on cyl 6. It’s the one with the green corrosion marks. Cyl 1 turned out to be a plug issue that was fixed prior to this mag check.

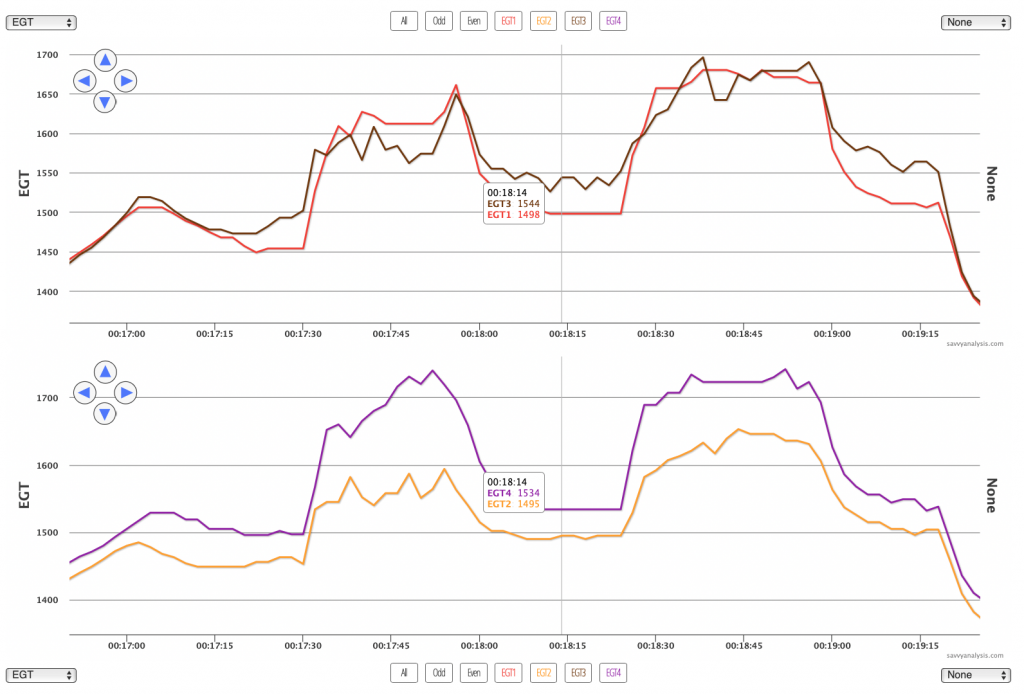

We’ll close this month with a Mooney M20J with a Lycoming IO-360 and data from a JPI 700 with a 2 sec sample rate. There was some roughness in cruise so we asked for a LOP mag check. Standard mag configuration – no electronic ignition.

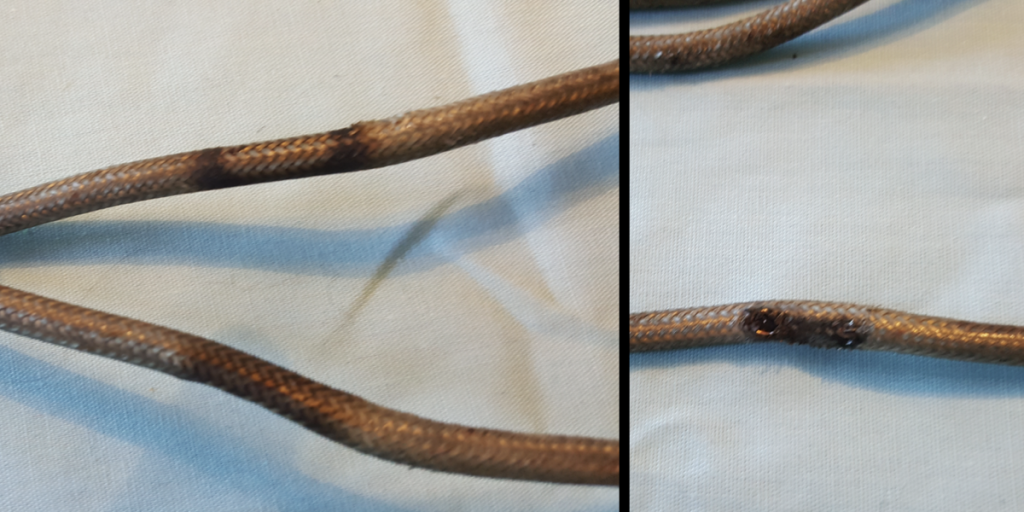

Cylinders 1 and 4 look ok. EGT 2 is wobbly on the first mag and EGT 3 is wobbly on both mags. With weak spark it’s tempting to start by pointing the finger at the plugs, and the plugs are often the problem. But if the plugs are newer, or if they’ve been tested and impedance is good, and insulators look good, we may need to look elsewhere. In the RV-10 scenario we saw that corrosion in the mag cap can lead to weak spark. This time it was the ignition harnesses.