Spring training is about to wrap up, and opening day is almost here. Last week a friend and I made our annual pilgrimage to Glendale, AZ to immerse ourselves in baseball. Four games in 45 hours. At least in Arizona, spring training and GA are good neighbors. The White Sox/Dodger park is next to Glendale, the Reds/Indians park is next to Goodyear, Padres/Mariners is not far from Deer Valley, Giants/Rockies is across town near Scottsdale and Falcon. So not only do you get a baseball game, you get to watch the traffic pattern, and a little higher and further away are the constant arrivals and departures at Sky Harbor.

I know a little bit about baseball, my friend is a walking almanac and former baseball writer. We sat behind a lady keeping score – on paper in a spiral notebook – and I wondered if I could explain engine data analysis to her faster than she could explain the arcane symbols of scorekeeping to me. Her language has been around a lot longer than mine, but it’s interesting to think that in both cases, if you know the language, you can look at the data and recreate the event in your mind.

Baseball managers and scouts use the scoring data to properly position their players for maximum performance. In our marathon weekend, we saw the extreme infield shift for a left handed batter, with three infielders between first and second, leaving a huge gap from short to third. The batter grounded to the second baseman. So where would you position them next time? Same place, of course. Engine maintenance isn’t exactly a sport, but writing a big check for unnecessary or unsuccessful troubleshooting can feel like the losing side of a slugfest. Ideally, we can use engine data to stay out of the loss column.

Induction

Interesting that we use the same term for the Baseball Hall of Fame and the air for our engines. We demand a lot less of the air than of the player, but there is an agreement that the air will start here, then proceed over there, and wind up where it’s needed for combustion. A leak-free induction system is a critical component of proper mixture distribution and power management.

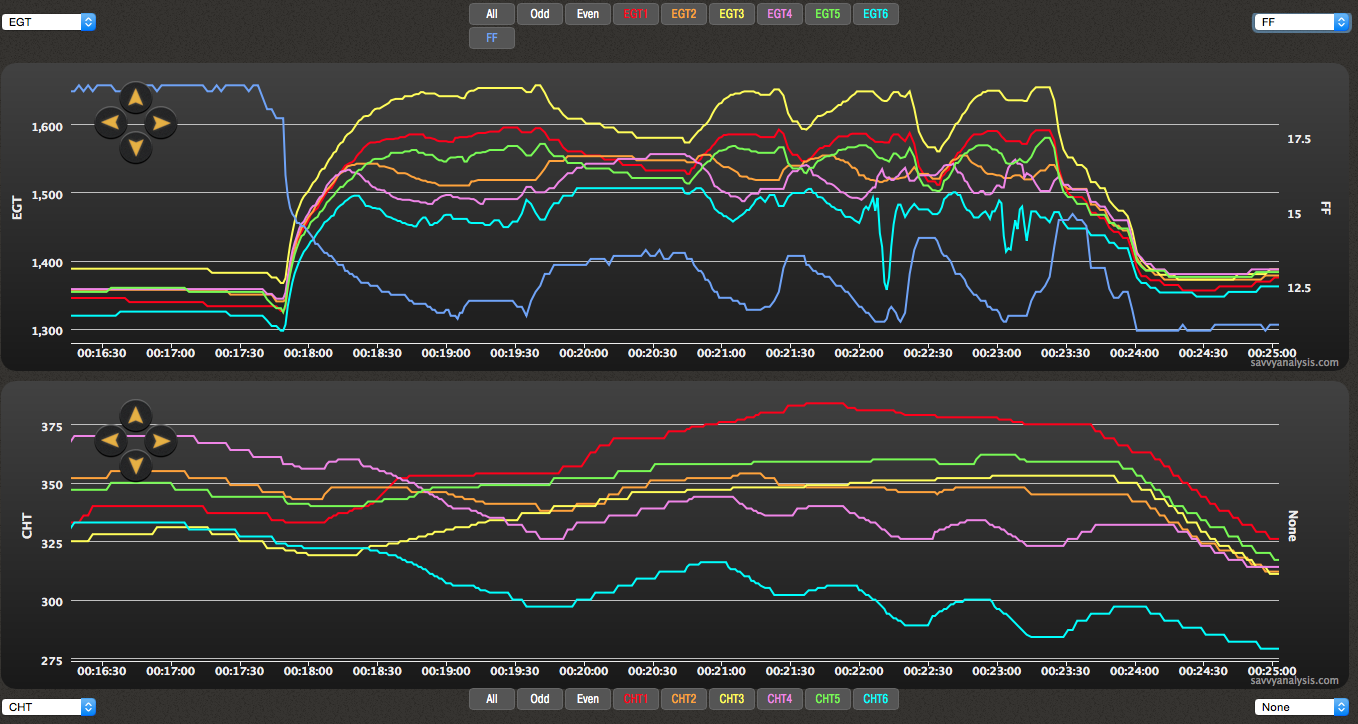

Here’s a screenshot of an IO-470-K in a Beech 33 Debonair. The blue trace is fuel flow. As the mixture gets leaner, the odd cylinders rise as expected, and the even cylinders fall. Manifold pressure is not depicted but is unchanged.

Most Savvy users are familiar with the GAMI sweeps and LOP mag check in the Savvy Test Profile. There are also instructions for an induction leak test. We compare EGTs at a high MAP with a lower MAP. We calculate EGT change for each cylinder. The delta-P should be about the same for all – if one or two cylinders have a smaller EGT change than others, that indicates an induction leak in the vicinity of that cylinder. Keep in mind that we want a full-rich mixture so we know no one cylinder is LOP, and that should preclude an EGT increase on any cylinder as manifold pressure is reduced.

In this case, the leak is effecting all three even numbered cylinders, suggesting that the leak is on the throttle body end of the tubing, in the vicinity of cylinder 2. We reported that to the owner, and he reported back that soft couplers and clamps were replaced during recent maintenance. That left us puzzled. If it wasn’t an induction leak, what else would make one side run leaner than the other with the same fuel flow? Three clogged injectors – all on one side? Not likely. Three bad plugs – all on one side? Also not likely.

The owner submitted new flight data and again it pointed to an induction leak in the vicinity of cylinder 2. We asked him to check again and this time he pressurized the tubes and used the soapy water test, then reported that one of the clamps was only finger tight – loose enough to cause a leak. He tightened the clamp, submitted new data showing all EGTs rising as fuel flow is reduced, and the engine operating normally. Puzzle solved.

Your Engine Sucks

It’s not a criticism – they’re designed to suck. When the intake valve opens and the piston falls away from top dead center, it’s sucking in air for the next combustion event. When you reduce the throttle, you’re requesting less air to pass through the induction system. If the induction tube or the seals between them are making their own side deals regarding air, then your throttle is only partially effective.

Savvy’s founder and CEO Mike Busch has written extensively about maintenance induced failures. The induction coupling in this puzzler seems to fall into that category. But there are also failures that occur from lack of maintenance, or from sitting idle. Spring training is a time for ball players to get back in shape after a few months of taking it easy. Some stayed active playing winter ball, but many more didn’t. That’s probably true of the GA fleet, too. If you did little flying over the winter months, and you notice something strange, Savvy’s analysts are ready to help your airplane play at the top of its game.