Most of the time engine data is an important tool for helping us with powerplant management during a flight, and choosing efficient options when maintenance is needed. If you’re a regular Puzzler reader, you’ve seen lots of examples of that. But every once in a while, the data is so erratic or mysterious that it can cause distractions or confusion.

Every flight starts – or should start – with good preflight planning. For short trips, your planning might start a day or two ahead. For longer trips, you might start checking weather several days ahead, and maybe explore different options for rest breaks and fuel stops along the way. Ultimately all your planning leads to that moment when you start the engine and taxi out for takeoff and encounter the real-world weather and the airplane’s condition. Engine data helps us assess the airplane’s condition.

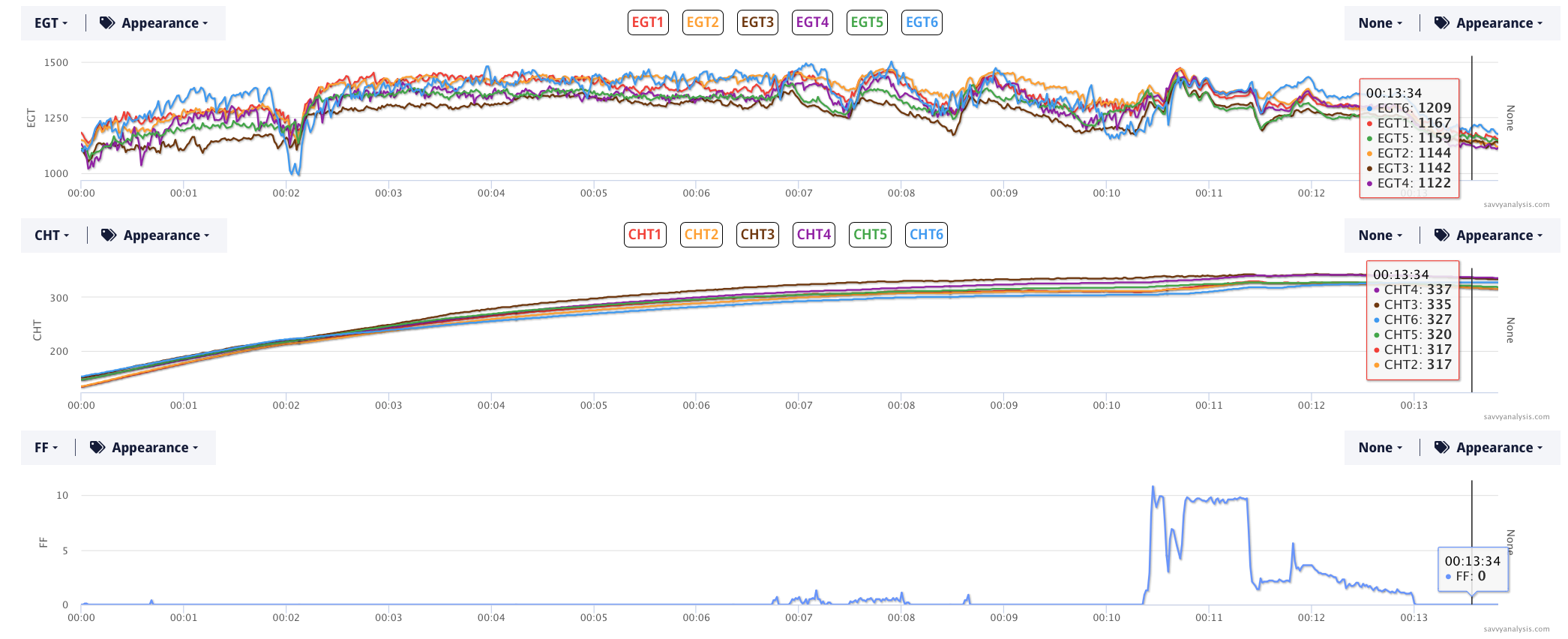

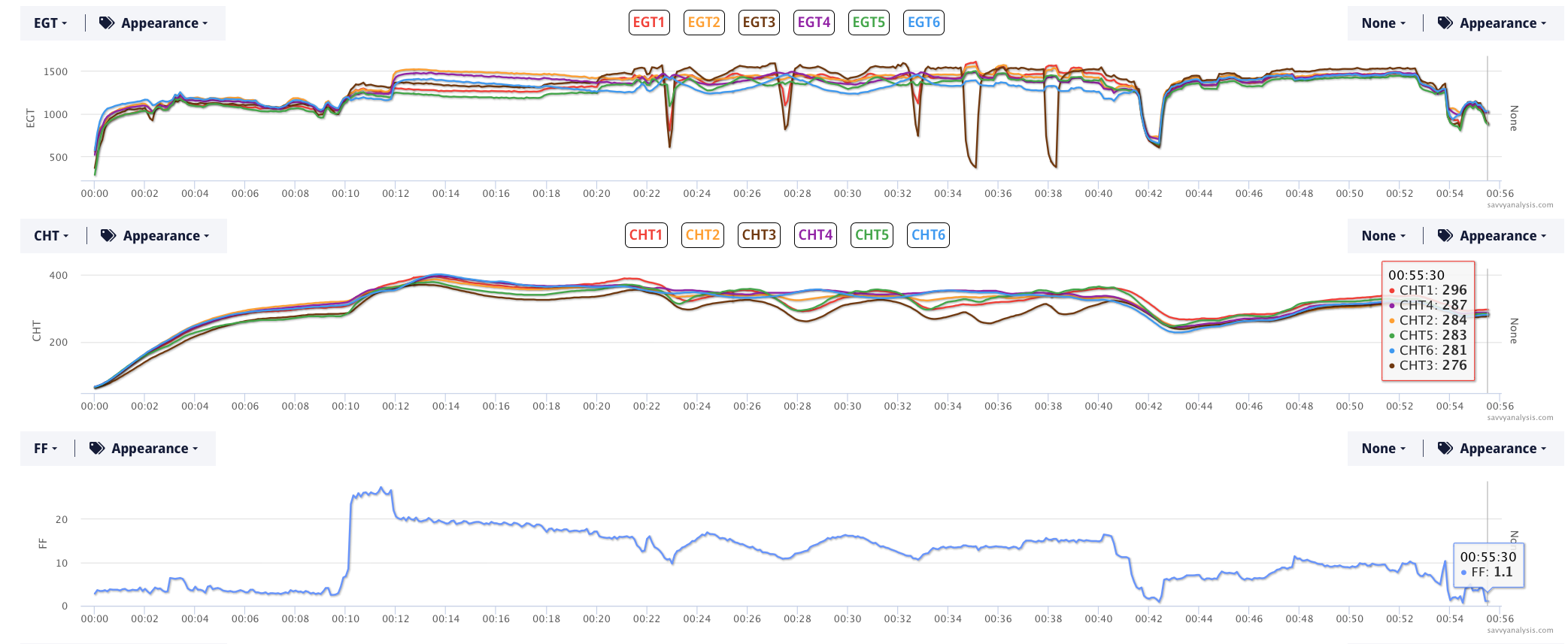

This is taxi-out and runup data from the first 14 minutes of an hour and 25 minute flight of a Piper Saratoga powered by a Lycoming IO-540 and data from a JPI 830 with a 1 sec sample rate. EGTs, CHTs and FF. Nothing special about cursor placement – just getting it out of the way.

Let’s remember that the pilot didn’t see this depiction. The pilot saw a set of numbers each second. and that’s if the JPI 830 was sent to display EGTs.

The JPI might have been set to scan, in which case the bottom row of big white numbers would’ve been scrolling through the various parameters every few seconds. EGT (whichever one was chosen by the white square box), then CHT (again, the one chosen), then Oil temp, oil pressure, FF, and all the available data – one at a time.

One thing that would’ve been hard to ignore, though, is FF reading zero for most of the taxi-out. During runup it comes off the pegs and looks about right, before dropping to zero again.

Meanwhile, CHTs look normal and unperturbed.

My point in showing this data wasn’t to criticize or second-guess this pilot, it was to get you to think about how to monitor your data in real time. If your FF sensor showed zero during idle, but looked normal during run-up, would you take off and hope you got a realistic number during climb and cruise? If your EGTs were jumping around, but your CHTs were ok, and your legacy CHT gauge (which most of us still have) looked normal, would you take off and try not to be distracted by the jumpy EGTs?

What if your taxi-out and run-up data looked ok, but you got strange readings during the take-off roll?

Are strange readings enough for you to scrub a flight? Or do you need some haptic corroboration like engine roughness to pull the plug?

Would the answers change depending on who’s flying with you, or weather conditions?

If you’re reading this hoping for the “right” answer, sorry. It’s different for each of us, and might be different from day to day or mission to mission. What’s important is that you find the right answer for you each time you fly.

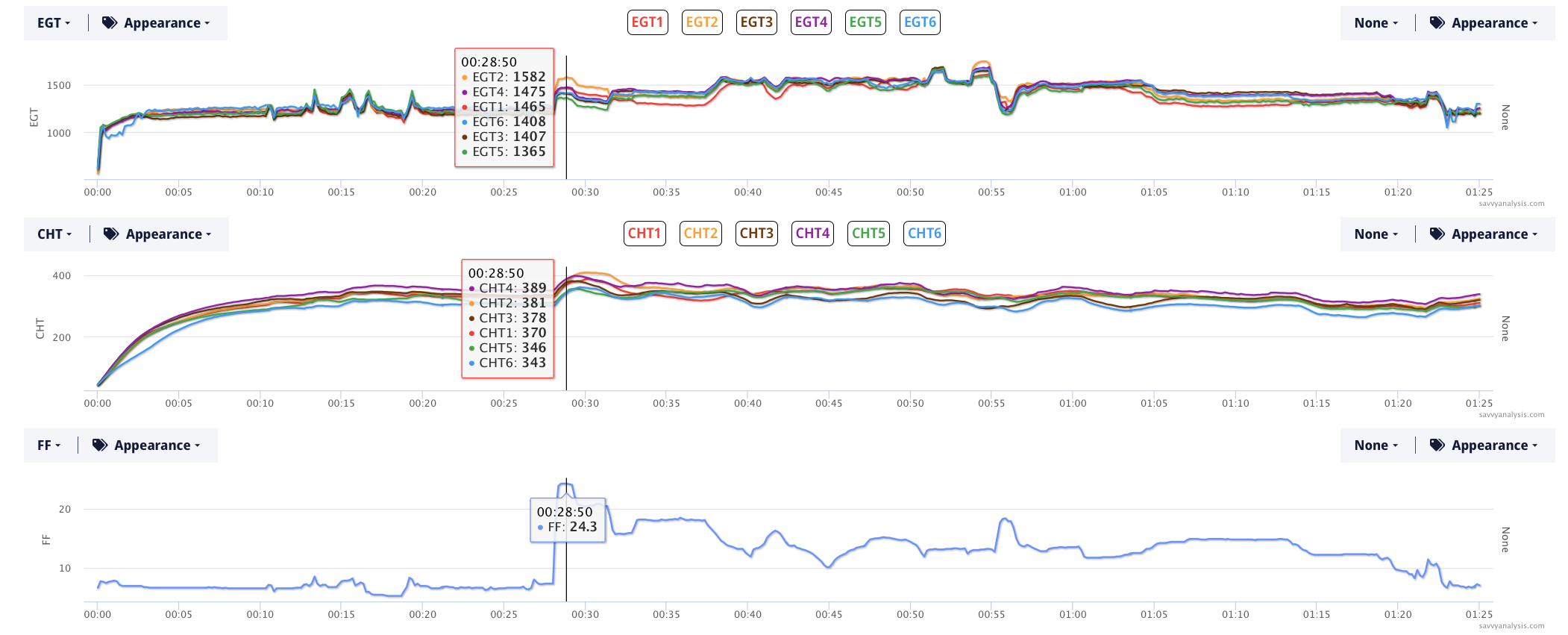

Here’s data from another hour and 25 min flight. This time it’s a vintage Bonanza 35 powered by a Continental E225 engine. Data is from a newly-installed JPI 900 with a 1 sec sample rate. This is a test profile flight with mixture sweeps starting at 37 mins and the LOP mag check at 50 mins. Cursor is at takeoff.

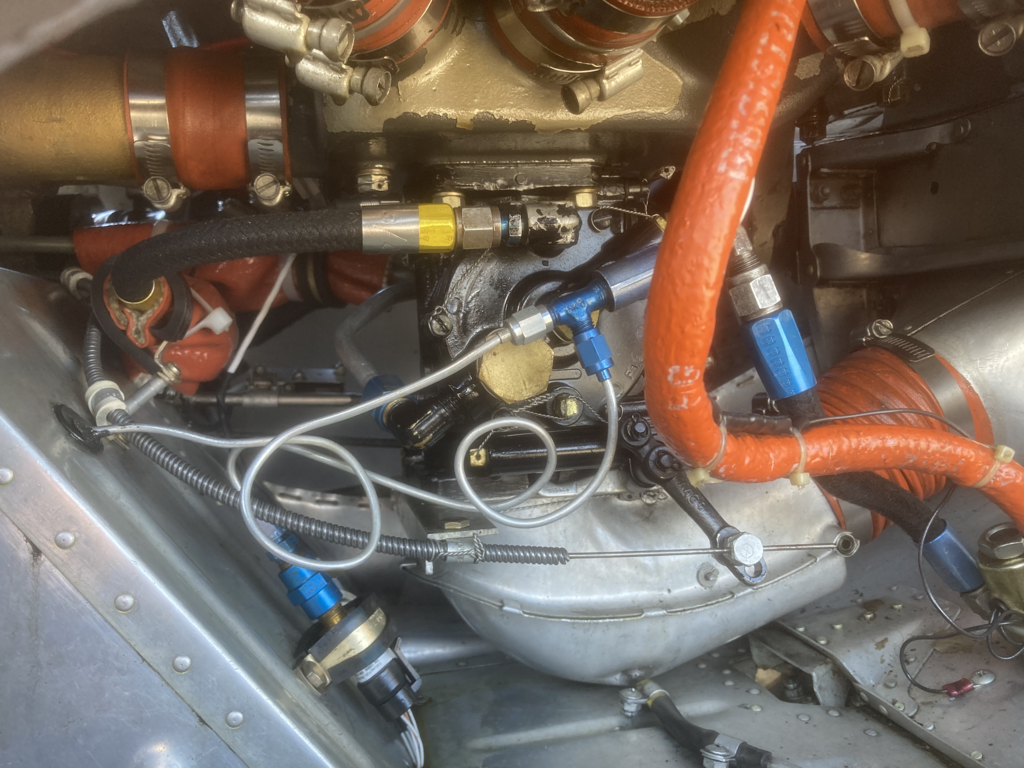

Our client thought the FF numbers looked off. Our experience is that JPIs deliver really accurate and dependable FF numbers once the K-factor calibration process is completed. So we recommended that. And our client was also concerned that the FF sensor might have been hooked up improperly, and he submitted this picture.

This client has the QA service so we sent the ticket to Brandon Thompson. Brandon noted three issues with the installation.

1. Rubber fuel hoses with no firesleeve. Replace those hoses with Teflon hoses with integral firesleeve.

2. The aluminum rigid line is BAD. Replace it with a flexible hose. The fuel flow installation manual will tell you that the transducer needs to be suspended between two flexible hoses, and that the hoses need to be straight fittings in / out of the transducer, all fittings should be steel, and the hoses need to be properly clamped on both sides. They even draw pretty pictures most of the time. This is no bueno.

3. The fittings on the servo should be steel, not aluminum.

Even zoomed out you can see that cyl 1 isn’t tracking with the others during the sweeps. Let’s get a better look at that. Here’s the last of the sweeps starting at about the 45 min mark. The bold blue line is FF.

This engine has a pressure carb, so no injectors to clean or swap. Induction seems like a good to place to start to bring cyl 1 closer to the others and improve mixture distribution.

In the first case we saw sensors that looked sketchy, or at least noisy. In this case the data was ok – it’s the sensor installation that makes you wonder if we’d be better off without it.

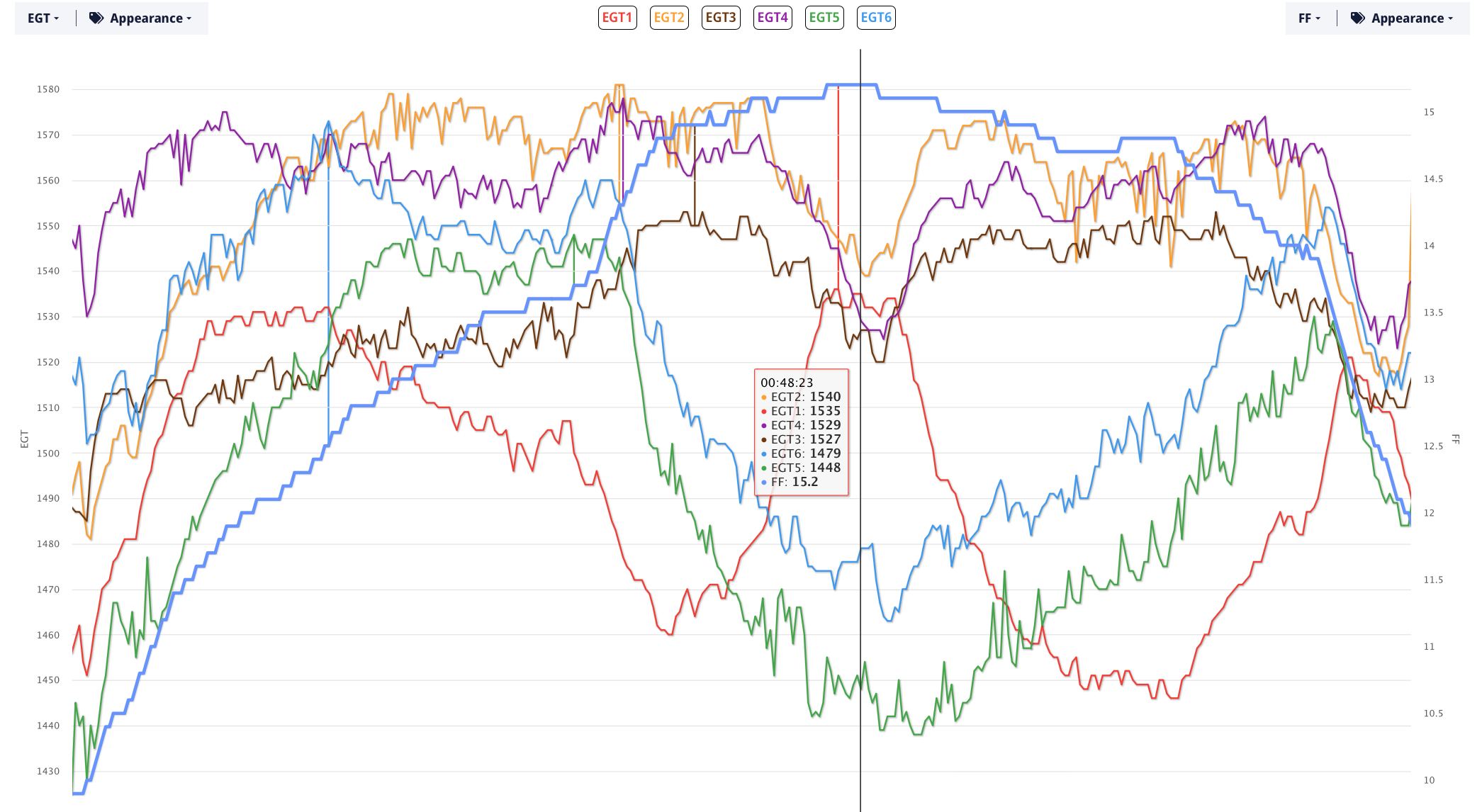

We’ll finish May with a 55 min flight from a Cessna 182 with a Texas Skyways O-550 engine and data from a JPI 800 with a 1 sec sample rate. This is another test profile flight with mixture sweeps and a LOP mag check. EGTs, CHTs and FF. Nothing special about cursor placement. Just getting it out of the way.

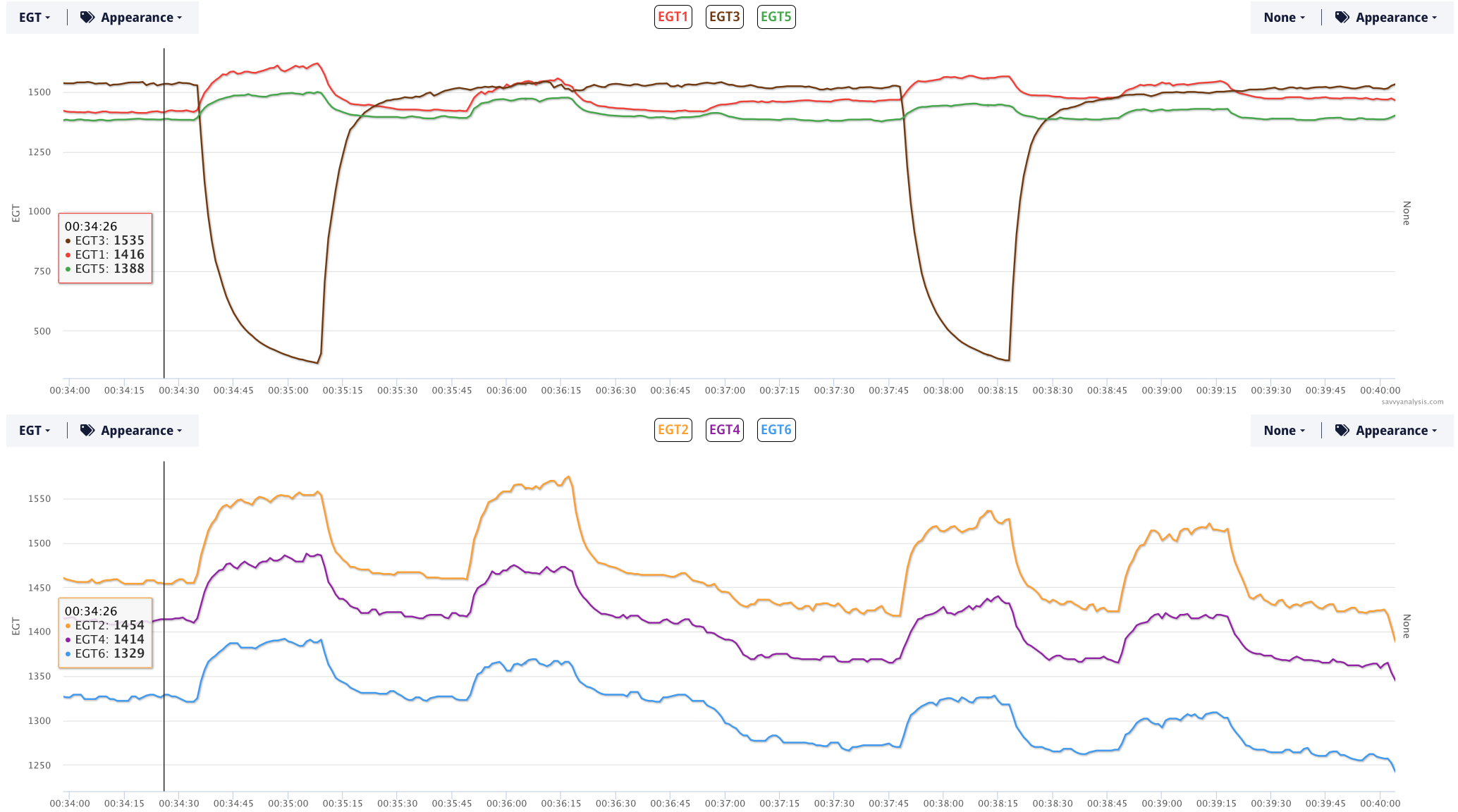

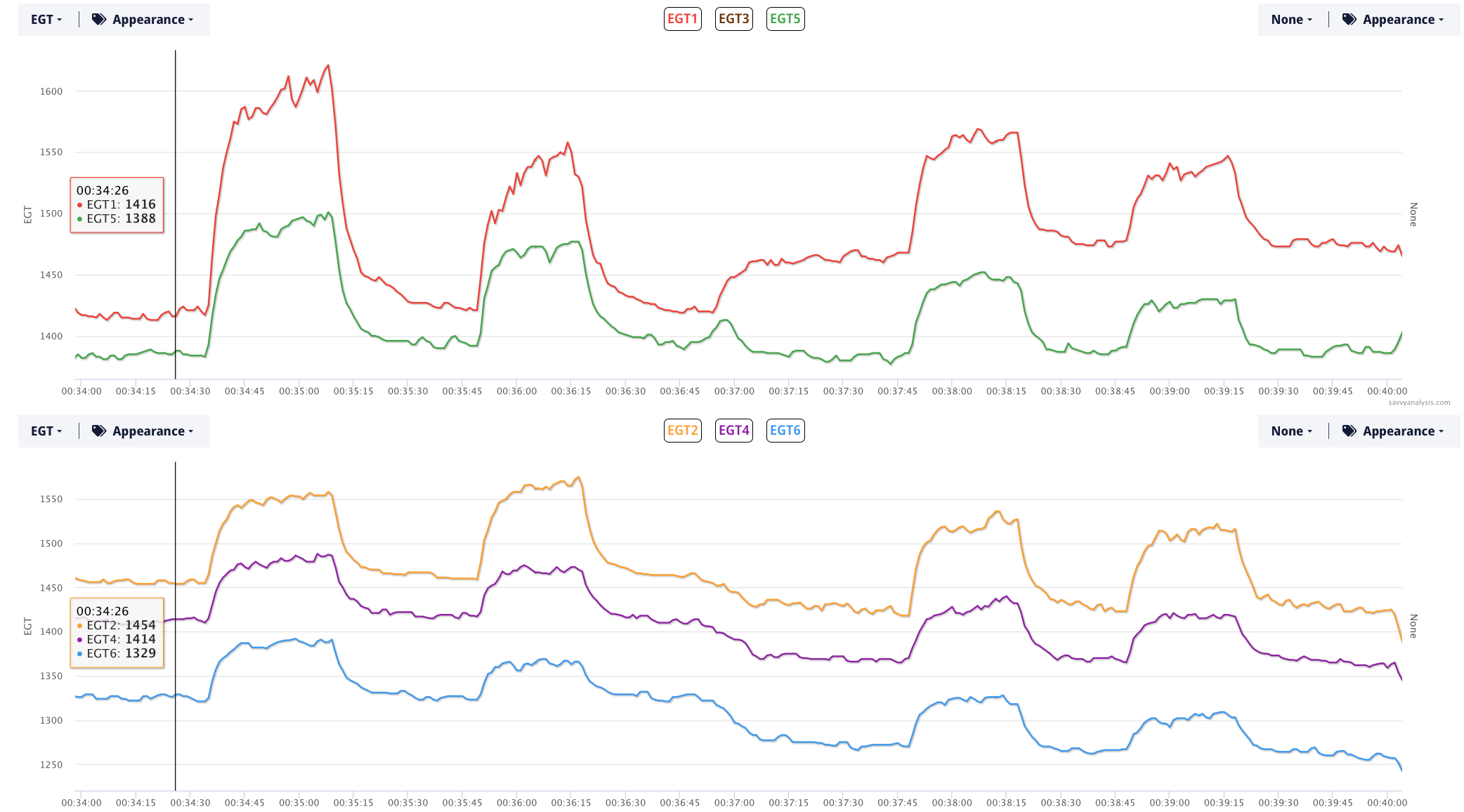

Let’s zoom into the mag checks starting just after the 34 min mark.

We’ve got one L-BOTH-R mag check just to the right of the cursor, then another of those at 37:45. One of the plugs of cyl 3 isn’t firing. Which one? Let’s hide EGT 3 so we get a more informative Y-axis.

Now it’s easier to see that the first mag checked shows the bottom plugs of 1-3-5, so it’s the bottom plug of 3 that’s not firing. Going back to the first zoomed-out chart, EGT 3 shows a big drop when FF is leaned in the sweeps. Here’s the GAMI data from the sweeps —

00:24:58-00:26:26

EGT1 peaked at 14.4

EGT3 peaked at 14.2

EGT5 peaked at 14.2

EGT2 peaked at 13

EGT4 peaked at 12.7

EGT6 peaked at 12.7

GAMI spread is 1.7

1-3-5 are consistently leaner. 1.7 GPH is a typical spread for a carbureted engine.

No better off without it here. In this case the data pointed right at the problem, and the client decided to change out all the plugs. His thought was that since they’re all the same vintage – and he thought he had got his money’s worth from them – changing them all was preferred over running the others to failure.