I never had the guts to do it, but I sure thought about it more than once. Maybe you’ve done it or thought about it. You know – you’re in a mandatory meeting about some new company policy or initiative and the presenter is droning on from a pamphlet – or worse, a PowerPoint that you can read yourself – and the cliches and buzzwords start flying. Maybe it’s unique to your industry, or maybe it’s just general management and productivity cheerleading. The first participant to recognize five cliches in a row stands up and yells “Bingo!” – then more than likely goes back to his office, cleans out his desk and starts looking for a new job.

Bingo Fuel has a specific meaning to Naval aviators who are down to the minimum fuel required to ensure a safe landing. My SavvyAnalysis colleague Paul Kortopates, who is Lead FAASTeam Representative and San Diego IMC Club CFI and Co-Coordinator, recently reminded civilian pilots that they should be saying “Minimum Fuel,” even though it’s not as cool as saying “Bingo.”

- Controllers JO 7110.65 and AIM 5-1-10 defines:

- “minimum fuel” indicates recognition by a pilot that his/her fuel supply has reached a state where, upon reaching destination, he/she cannot accept any undue delay.

- This is not an emergency situation but merely an advisory that indicates an emergency situation is possible should any undue delay occur.

- A minimum fuel advisory does not imply a need for traffic priority

- If, at any time, remaining usable fuel supply suggests the need for traffic priority to ensure a safe landing, the pilot should declare an emergency and report fuel remaining in minutes.

- “minimum fuel” indicates recognition by a pilot that his/her fuel supply has reached a state where, upon reaching destination, he/she cannot accept any undue delay.

I can’t use “Bingo” on the radio, so for me it means “there are too many inoperative or untrustworthy devices for me to safely begin or continue this flight.” For instance, lately one of my JPI EGT probes has been flashing BAD PROBE or OPEN PROBE, but the data from that probe seems normal in flight and after uploading. So far no bingo. But two or more probes failing would trigger bingo for me. Chances are you have your own standards or minimums for what you’re comfortable with. Let’s look at this month’s data and see if we can fill up a card.

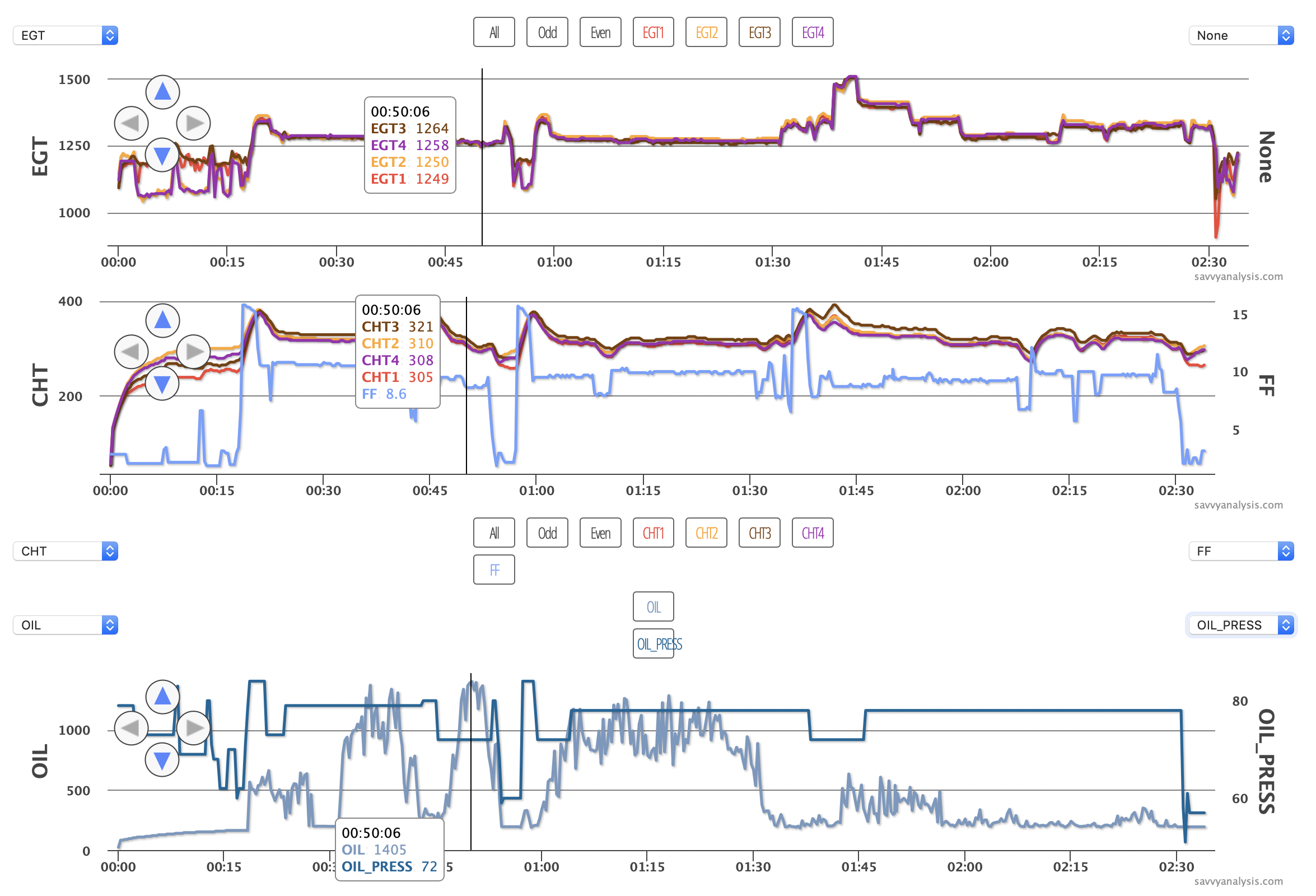

First up is data from a Piper Arrow III with a Lycoming IO-360 and data from a JPI 730 with a 6 sec sample rate. EGTs on top, CHTs and FF are next, and oil temp and pressure below that.

Note the cursor is parked on the peak oil temp of 1405º – that’s Fº, as if it matters. We’re 50 mins into a 2 hr 30 min flight and oil temp has already completed one excursion to this area, then back to normal. The flash point of engine oil is somewhere under 500º F so a legitimate sustained temperature above 1000º should have ended lubrication and caused the engine to seize by now. Since it’s still flying, and continues for another 100 mins or so, and other data shows no abnormalities, this is clearly an indication error.

Now the question becomes is it the oil temp sensor or the connection? It’s cheaper if it’s the connection and all we have to do is tighten a screw, but a connection will typically toggle between normal data and zero. This data looks more like a failed sensor.

If you saw this in real time would you bingo and land at the next airport? The engine’s running normally, everything except oil temp looks normal, and if you have a legacy oil temp gauge showing a steady, normal temp – which you probably would since the JPI 730 is not a primary instrument like the 900 or 930 – no bingo. Continue the flight.

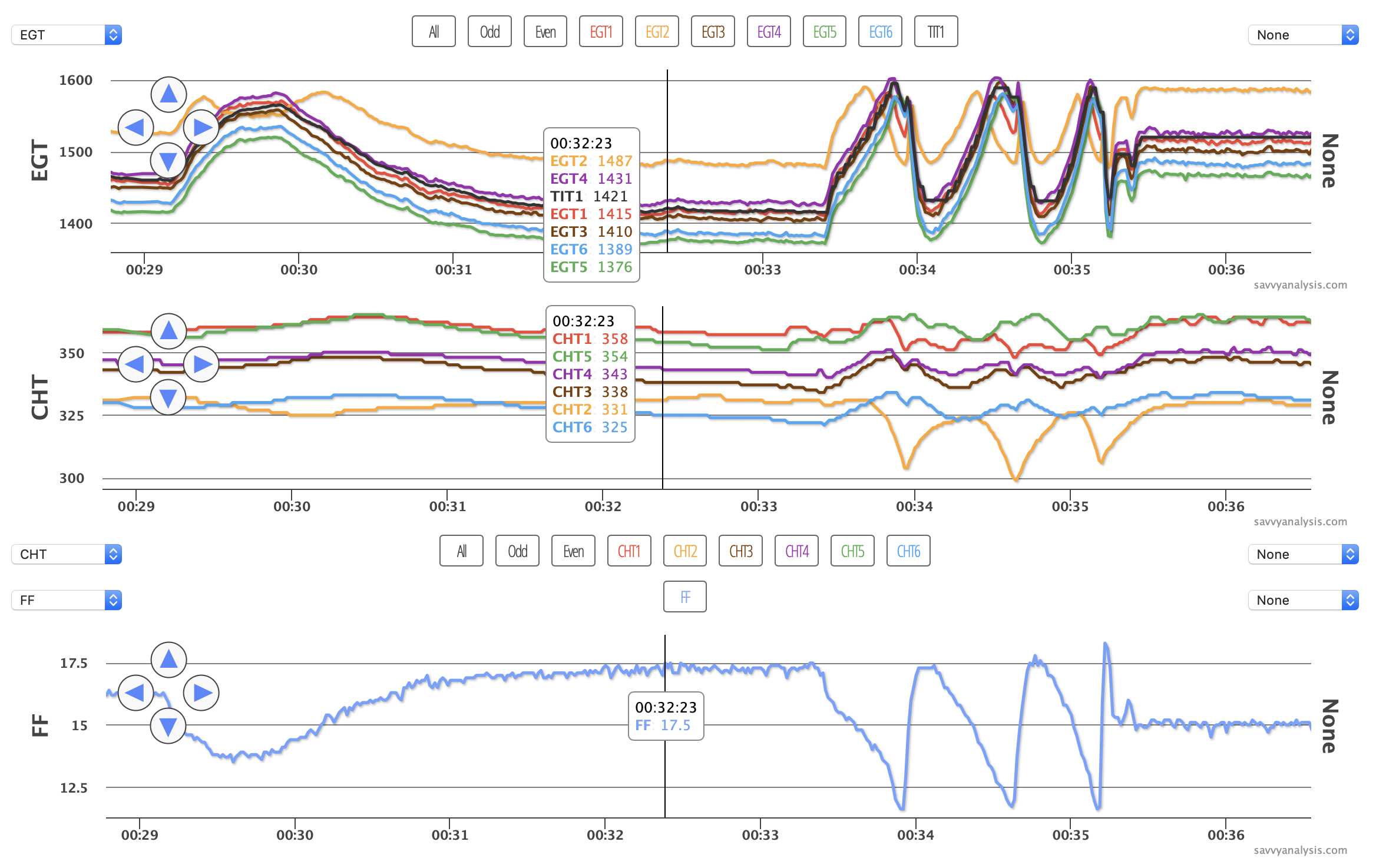

Next up is data from a Cessna Turbo 210 with a Continental TSIO-520 and data from a JPI 930 using a 4 sec sample rate. EGTs on top, CHTs below and FF below that. Nothing special about where the cursor is parked.

I selected this segment of the flight because it shows EGT 2 – the yellow trace – running high in cruise and peaking first in the mixture sweeps. Peaking first suggests a clogged injector, so we look to CHT for corroboration. With restricted fuel, CHT 2 should run high at max FF then it should drop along with EGT at reduced FF. CHT 2 drops dramatically during the low point of the sweeps, but isn’t really high at higher FF.

We’re not comfortable recommending maintenance if the data doesn’t support it, so while we were trying to make a case for cleaning injector 2, the shop noticed something interesting. The fuel line feeding cyl 2 was different than the fuel line for cyl 1 – its mirror-image. Further inspection revealed that cyl 2 was using the part number for an IO-520, not a TSIO-520.

One clue that helped was this problem showed up in the data after a maintenance event. So it made sense to check the logbooks for which items had been addressed, and the dots were connected.

This is the first time we’ve seen this particular scenario – an undersized fuel line resulting in low FF for a particular cylinder. But now we have an idea of what to look for.

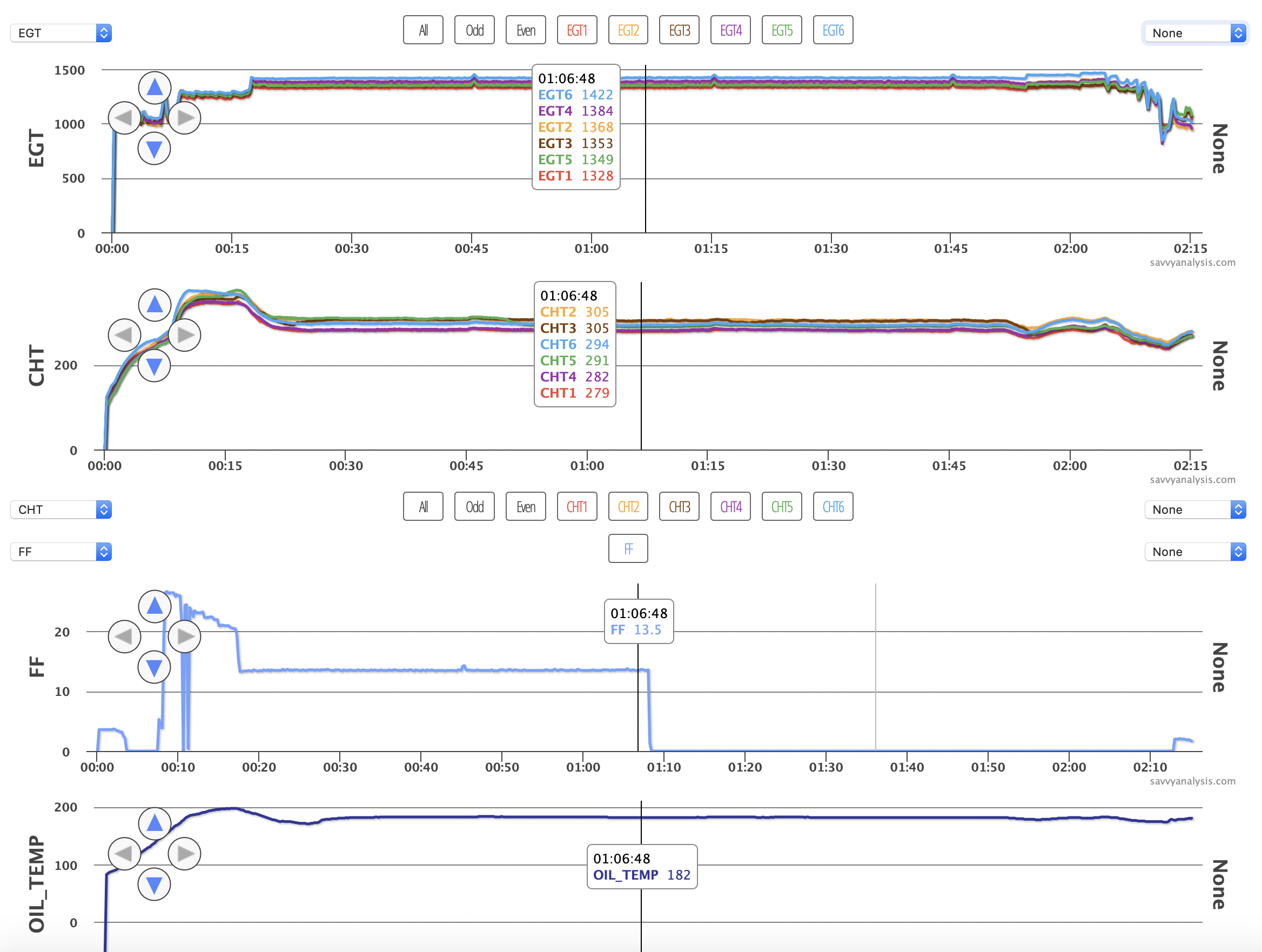

Next up is data from a Cirrus SR22 with a Continental IO-550 and data from an Avidyne with a 6 sec sample rate. EGTs on top, CHTs below and FF below that. The cursor is parked just before FF drops to zero.

More precisely, FF drops to zero for the last time, but it had dropped during taxi-out, and twice briefly in the climb. Then after about an hour it dropped to zero. I’ll bet you’re thinking gee, that’s about when I would be switching tanks on a 2 hour flight. We don’t know for sure but that’s a good guess.

In any case, no bingo fuel emergency here and the engine keeps running for another hour or so. In fact, FF starts logging again right before shutdown. The toggling between normal and zero suggests a connection problem.

If you look closely at EGTs and CHTs during approach – starting just before the 2 hr mark – EGTs and CHTs for 2-4-6 rise while 1-3-5 don’t. We’d expect an induction leak to become more prominent as the difference between ambient pressure and MAP increases – like the power reduction during approach. So while the cowl is off to check the FF connection, it makes sense to look at the induction for 2-4-6, too.

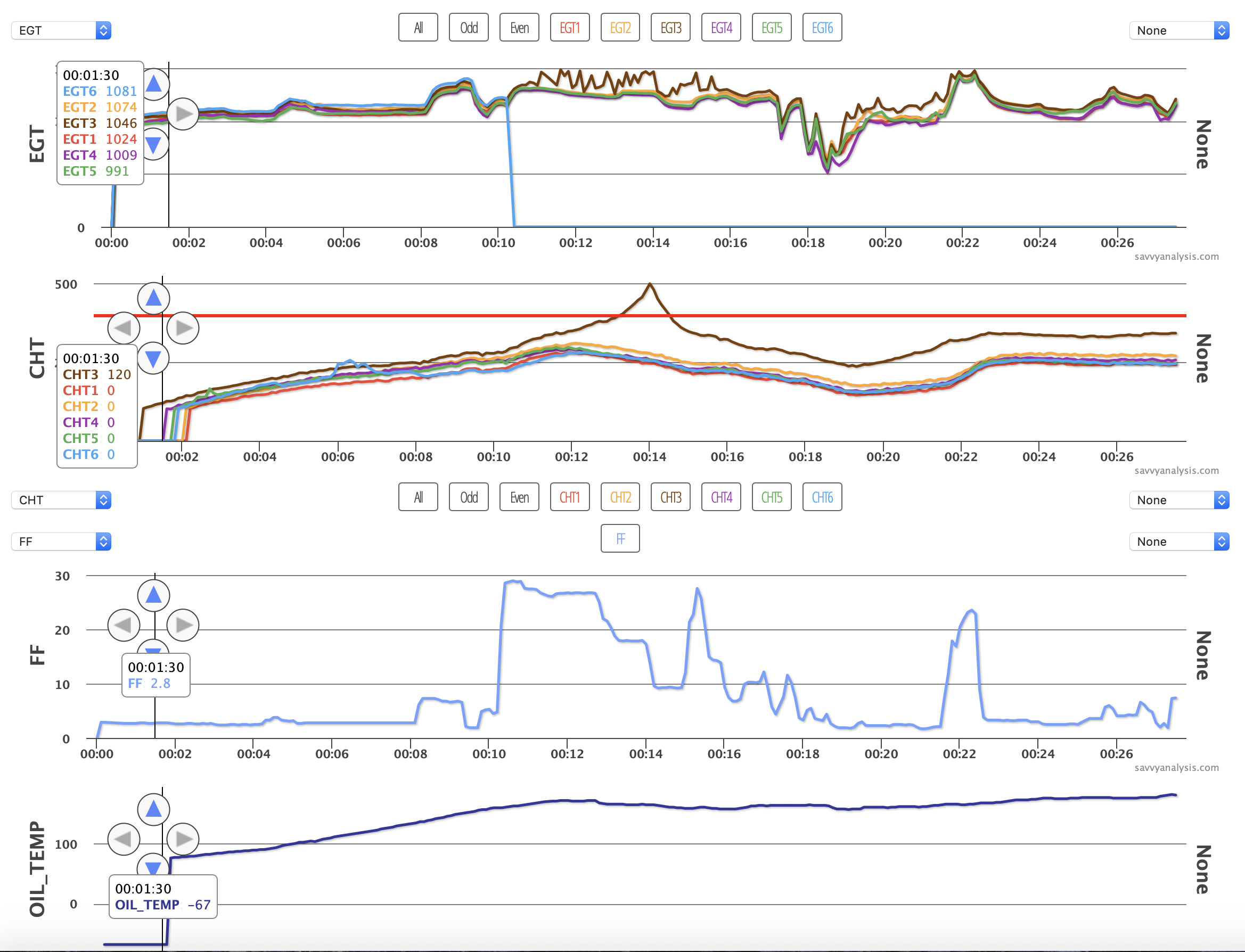

Let’s finish this month with data from another Cirrus SR22 with a Continental IO-550 and data from an Avidyne with a 6 sec sample rate. EGTs on top, CHTs below, FF below that and oil temp on bottom. The cursor is parked to show CHT 3 – the brown trace – indicating 120º while the other sensors are still posting zeros.

So we’re already suspicious of the CHT 3 data – and hopefully we noticed that anomaly at engine start so we can factor it in with what we’re about to see. On taxi-out CHT 6 is a little wobbly, but it settles down and the runup looks normal. When takeoff power is applied, EGT 6 drops directly to zero – it does not pass GO or collect $200. But that’s not what’s grabbing your attention. EGT 3 is jumping around, and CHT 3 begins a steady climb that will end at 500º before it drops again.

No doubt there were multiple alarms happening. EGT 6 is showing zero, which on any other flight might cause some heartburn, but the more immediate issue is CHT 3 which is being corroborated by – or at least confused by – EGT 3. At the 14:00 mark when CHT 3 peaks, the pilot reduces FF from 18.0 GPH to 9.2 GPH, which ends the CHT 3 excursion, but EGT 3 continues to be trouble until power is reduced for landing.

Was this a detonation event? Let’s subtract the 120º that we were suspicious about from the peak of CHT 3 and there’s no problem – right? When you add in the unusual pattern of EGT 3, it’s pretty clear something happened, even if the 500º reading can’t be trusted.

We’d probably order a new CHT probe for cyl 3, check the plugs and harnesses for both plugs of cyl 3, and in abundance-of-caution mode we’d borescope cyl 3 looking for signs of detonation. If this didn’t meet your criteria for a bingo, remember there’s no guarantee that the next flight might not be worse.