I’ve been training new analysts recently, and I thought I would share some thoughts about continuity. Of course signal continuity is important for sensors and probes so we have reliable data to perform actionable analysis. I’ve made this point before and if you’re reading this puzzler, you’re probably not the audience that needs to hear it, but think about what a series of flights with failed sensors and probes says to a prospective buyer about your approach to maintenance. End of rant.

One of my jobs in managing the analysis team is to deliver continuity in our work product. The nightmare scenario for me would be different analysts drawing different conclusions from the same data. So when we’re not sure about what we’re seeing, we confer with one another – and sometimes with the Savvy Mx and QA maintenance team – before we post our response. Sometimes that’s behind the scenes and sometimes it’s on the ticket where you can see it.

Typically the first step in working a new ticket is to review the history for this issue. Let’s say we’re chasing an induction leak. We need to know what has been tested and what’s left to try. It has to bug you when we ask for the same information twice. Just know that it bugs us too, and we try hard to avoid that. We have a system for reviewing related (previous) tickets. But here’s a rule of thumb about when to create a new ticket versus when to post to an already-existing ticket. If it’s a new issue that never happened before that’s clearly a new ticket. In fact, it helps if you resist the urge to post something about an electrical issue on a ticket that originated on a fuel flow issue. Apples and oranges in terms of continuity.

On the other hand, if you already have a ticket open about mixture distribution, and you’re giving us a fresh set of sweeps, that’s better as a post to the already-existing ticket. If you do open a new ticket, we’ll probably merge it into the previous ticket so all the info is in one place. We also have a preference for continuity in personnel. So all things being equal it makes sense for your new ticket to go to the analyst who worked the last ticket. Analyst availability and your preference for urgency would cause a change of plans.

One last thing. If you want us to look at multiple flights with the same issue, one ticket is enough. We often look at previous and subsequent flights as SOP, even if you don’t ask. Is there any harm in opening multiple tickets? Now we’re back to my nightmare scenario. So I would say yeah maybe there is. We can prevent that if we think about continuity.

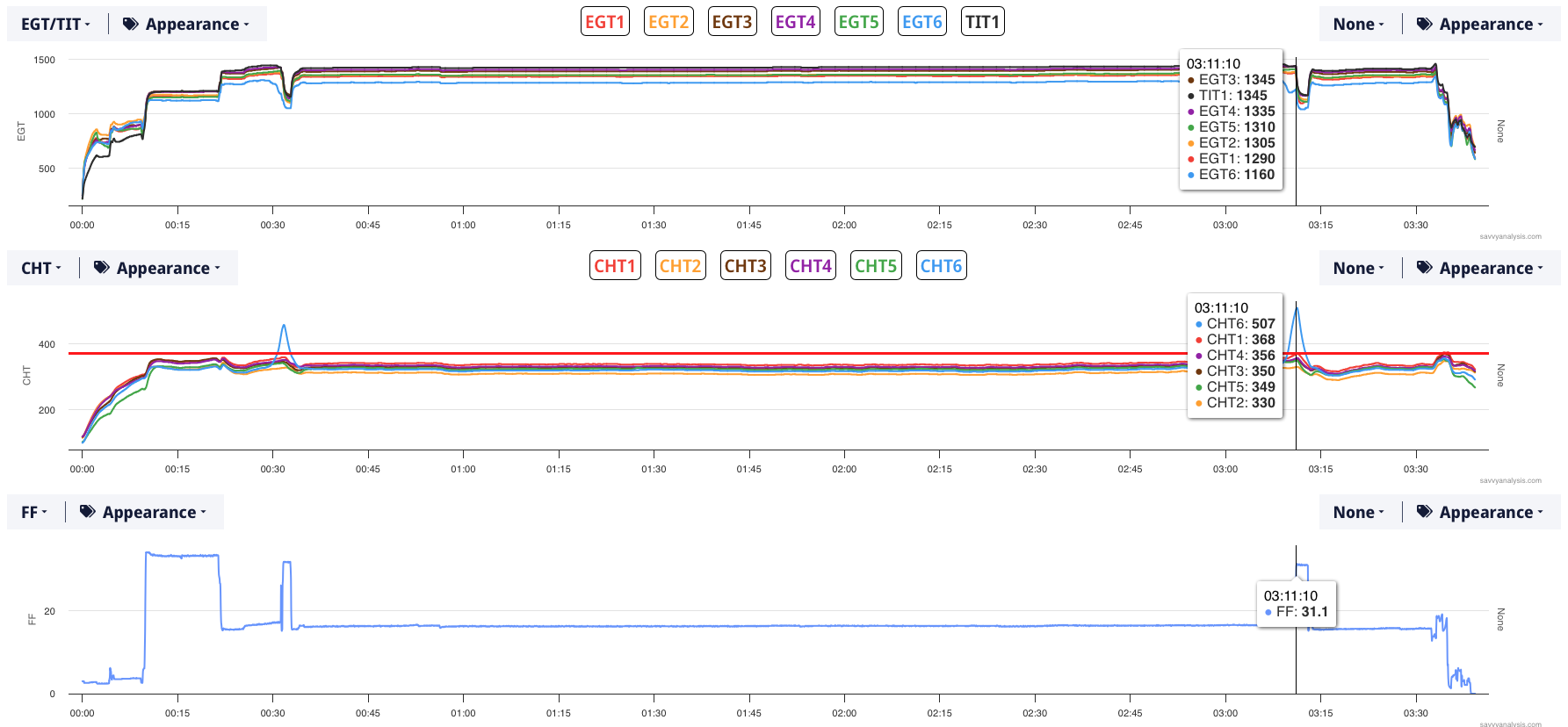

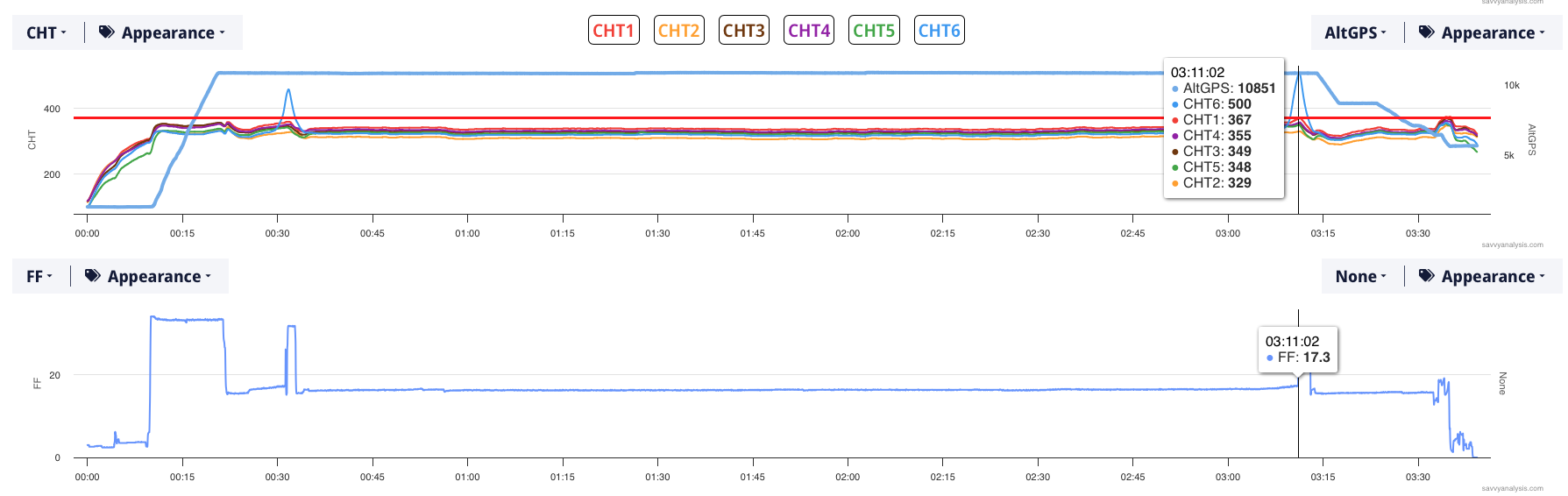

First up is data from a Beech Bonanza 33 aka Debonair powered by a Continental IO-550 TN with data from an EI MVP-50P with a 1 second sample rate. EGTs and TIT on top, with CHTs and FF below.

What’s the old line about hours of boredom and moments of sheer terror? It’s not quite that and you could say it was a pretty uneventful flight except for these two significant events. It’s natural to want to know why these events happened when they did and were they tied to or perhaps caused by a change in flight configuration so here’s the same full flight with GPS altitude depicted on the CHT rank.

Using our ∆/t tool shows an increase of 144º with a rate of 95º/min. That and the relatively small drop in EGT 6 suggest these are more likely pre-ignition events than detonation events. With detonation we usually see a slower rate for the CHT rise and a wobblier EGT after the event. In either case we’d recommend checking the plugs – especially the insulator – and borescoping the cylinder – especially the piston dome.

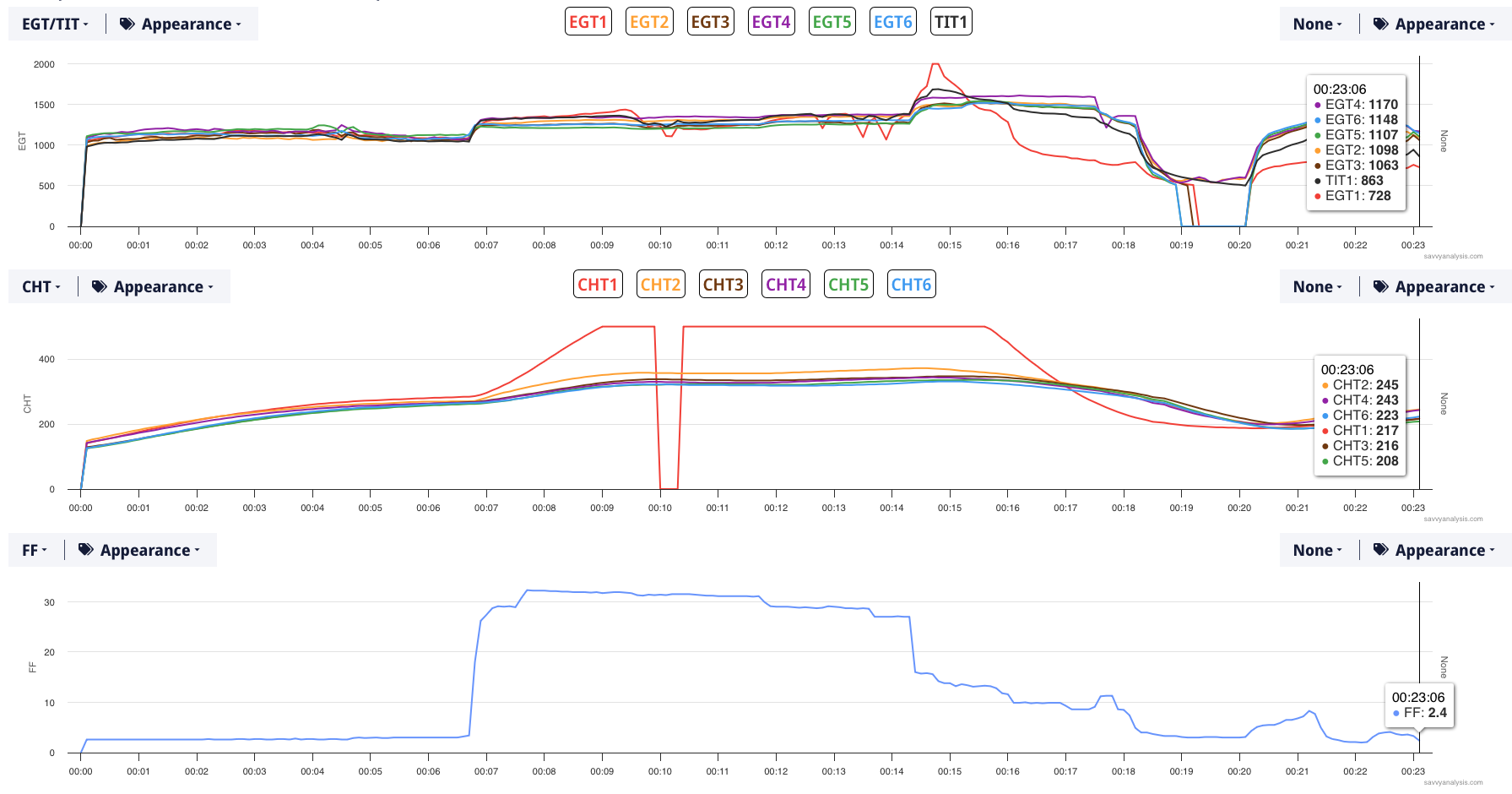

Next is a Cirrus SR22 powered by a Continental IO-550 TN with data from an Avidyne Entegra with a 6 second sample rate. EGTs and TIT on top, with CHTs and FF below.

Speak of the devil. Here’s a slower CHT rate of change – 52º/min which is about half of what we saw earlier – and a wobbly EGT 1 after the event. Typical detonation event, and FF is already rich so this pilot does not have the extra fuel to change the dynamic. That drop in CHT at 10 mins is just the probe saying “uncle”. Avidyne probes top out at 500º. At just before 15 mins we see EGT 1 briefly top out at 2000º. Again the recommendation would be to check both plugs and borescope cylinder 1.

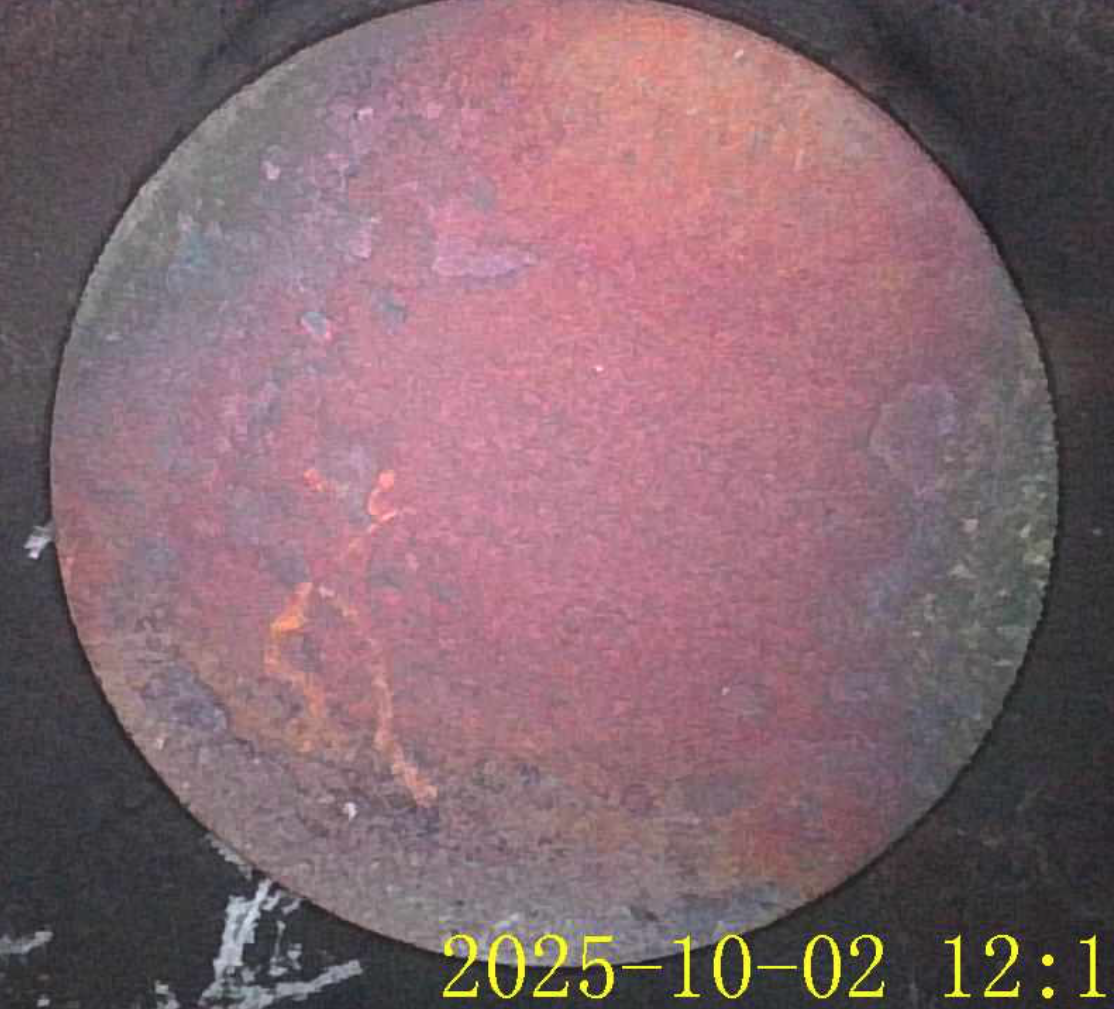

We’ll finish this month with a Cessna 182 powered by a Continental O-470 with data from an EI CGR-30P with a 1 second sample rate. This ticket came in as a borescope analysis request and we got a full set of 66 images. If that’s greek to you here’s an explanation of our borescope initiative. Four of the exhaust valves looked ok. One showed mid-stage uneven heating. Here’s the cylinder 3 exhaust valve.

What about lapping? We love it when lapping in place can keep a valve in service. This one’s too far gone.

Worth a try? We don’t think so, because after lapping, you have to put the engine back into service for the lapping to take affect. And on this valve, there’s just too much risk of either of those green discolorations failing catastrophically.

Clients often ask is there something in my power plant management that caused this? And the answer is in the other five valves. Four of them are OK and one needs to be watched, but they received the same power plant management technique that this one did.