If you’ve been flying LOP in cruise for a while you might forget that not so very long ago operating piston engines LOP was, shall we say – frowned upon. POHs didn’t mention it, except to say don’t do it. Some of the resistance was dismantled with the advent of multi-cylinder EGT gauges. But Insight and JPI didn’t lead the early charge for LOP ops, nor did TCM and Lycoming. Mike Busch was sysop of the CompuServe AVSIG in the early 90s, and he deserves credit for giving online aviators a forum for sharing ideas. George Braly from GAMI deserves immense credit, and kudos for giving us the product we needed to accomplish it. But the heavy lifting on promoting Wide Open Throttle and Lean of Peak as Standard Operating Procedure (WOTLOPSOP) was done by John Deakin.

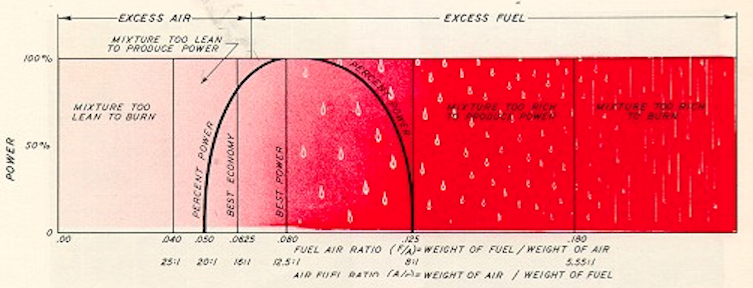

That’s Captain John Deakin of Japan Air Lines, and earlier Air America. And one of the senior pilots of the Confederate (before their name change to Commemorative) Air Force. You might know John’s Pelican’s Perch columns from AVweb. I have about 20 minutes of left seat time in CAF’s China Doll C-46 with John in the right seat. It may be the best single 20 minutes in my logbook. John found LOP while looking for a method to run CAF’s rare and expensive engines cooler, and discovered this graph from a 1955 Pratt & Whitney booklet.

The Twitter 120-character version of their research is too much fuel drowns combustion, too little fuel won’t support it, and left of center on the parabola will give you performance and longevity. John summed it up as “Leaner is cooler and cooler is cleaner.” These days, you’ll find John sharing his abundant knowledge at Advanced Pilot Seminars.

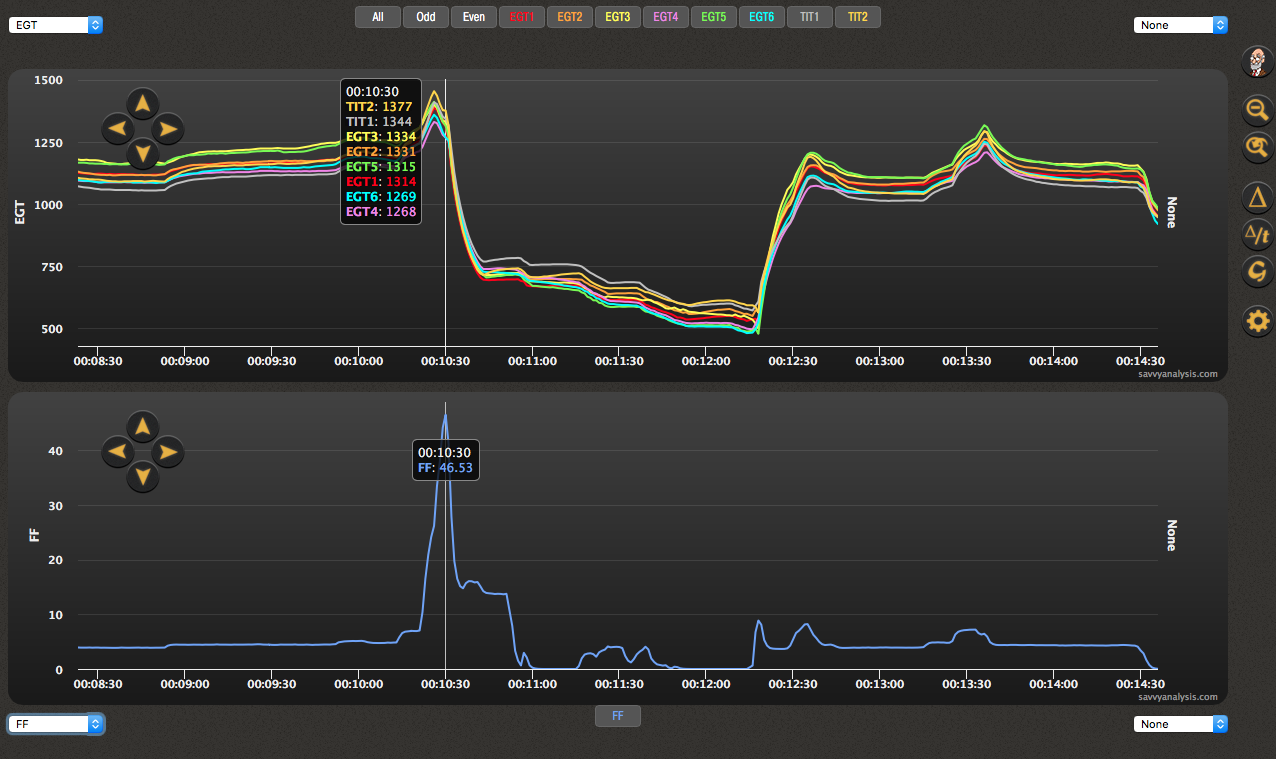

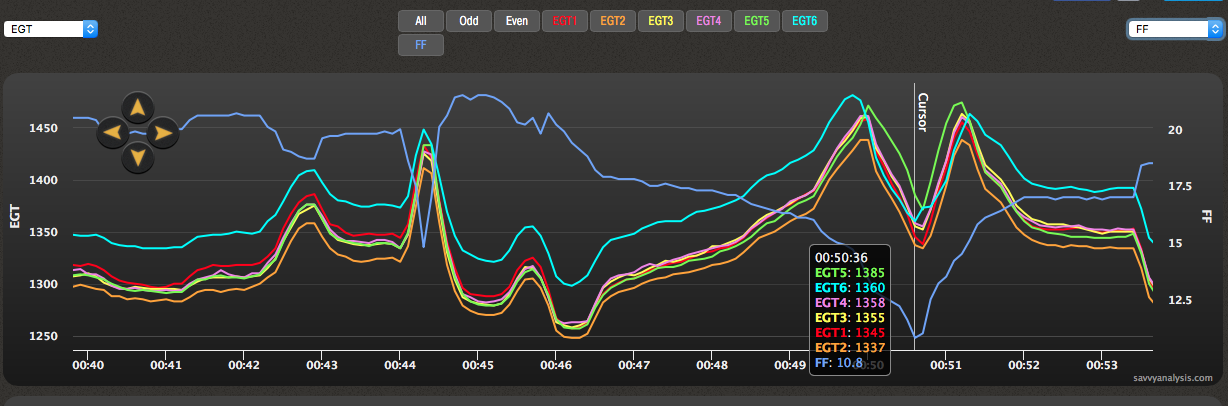

We don’t often get to see the right side of that parabola, where there’s so much gas that it won’t burn. But here’s one – an SR22 with a Continental TSIO-550, so we’re looking for about 40 GPH at takeoff (vs about 36 for a Tornado Alley 550.) EGTs are on top, FF is on bottom.

Looking closely, you can see that EGTs have already started falling as FF peaks. The pilot wisely aborted the takeoff and pulled power. Fortunately he was rolling, as opposed to adding this power at DH on an ILS. Although there your FF would likely be higher than the 2-3 GPH idle before the surge on this chart. Still, when we saw this we recommend checking max FF to get it closer to 40 from the 46 depicted here.

More common is the left side of the parabola, where combustion is marginal. Our LOP mag check is designed to identify weaknesses in the ignition system, so we’re intentionally wandering into the pink areas of the chart. Our test profile says “…as lean as possible” which – at least to us – implies “while maintaining combustion.” We want to spot combustion issues, but we don’t want to generate them.

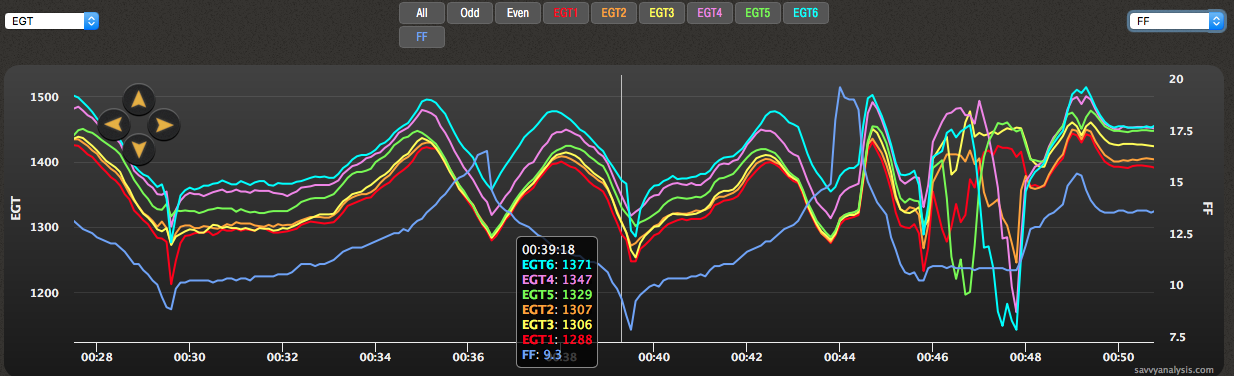

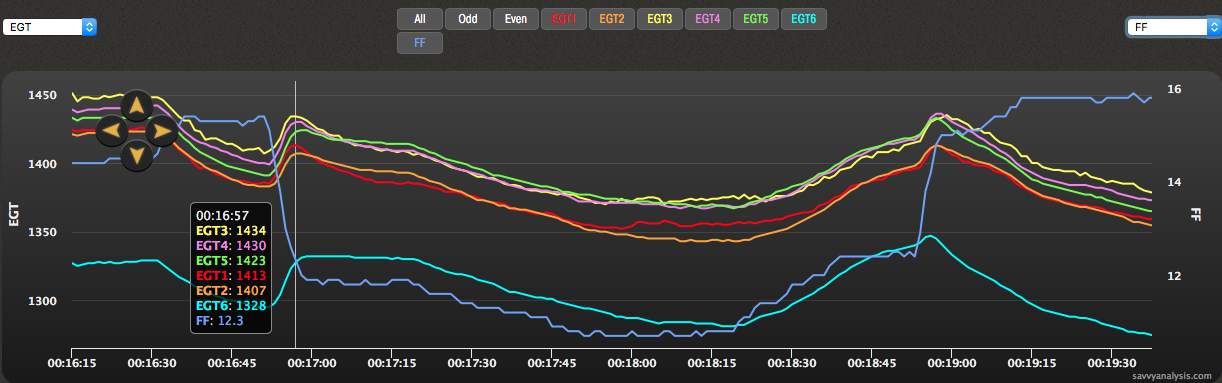

Here’s data from another SR22, this one with a normally aspirated IO-550-N. Notice that during the lean part of the mixture sweeps, with both plugs firing, combustion is sustained down to almost 9 GPH.

Here’s the same data zoomed in to the LOP mag check. To officially make this a Puzzler, what conclusions about injectors, mags and plugs can we draw from this mag check? Answer below…

Injectors look pretty good. 6 peaks a little late on the lean to rich sweep, and CHT 6 is high. But it wasn’t so clogged that it flamed out, even with FF around 9 GPH. This mag check would have been a rough ride. Looking closely, it’s the bottom plugs of each cylinder that run rough. Quick reminder – on this engine the L mag fires the tops of 2-4-6 and the bottoms of 1-3-5. The traces of the top plugs are ok. With a defective mag we’d expect to see all plugs from that mag showing irregular combustion. Not seeing that.

Can we conclude that all the bottom plugs – all 6 of them – are weak or defective? The odds of that would be lottery-like. One of the goals of analysis is to help troubleshooting be more accurate and effective, and save maintenance dollars. So when we see data like this, rather than jump to a faulty conclusion, we would usually request another LOP mag check with a slightly richer setting.

What’s the right mixture setting for your engine? Our test profile refers to “change of underwear” rough. In the interest of clean underwear, start with a setting that experience tells you will give good combustion. If it’s rough there, that’s a data point. If it’s not rough there, lean a quarter of a gallon and try again. You should be able to feel the burn – the effect of the leaner mixture on combustion way before any underwear issues arise.

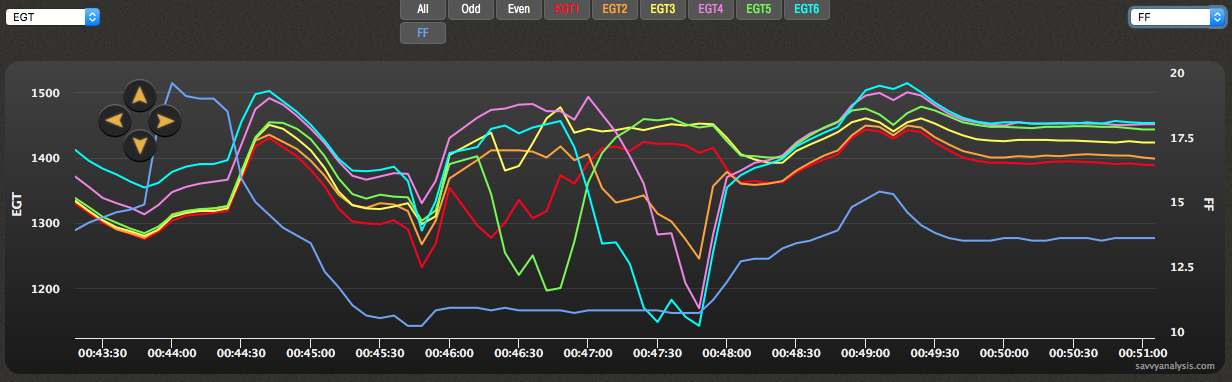

Here’s another SR22 IO-550-N. Mag check on the left of the chart, mixture sweeps on the right.

First mag checked at just before the 43 min mark. Everybody fires, but FF is 18 GPH. About a minute later FF dips to about 14 GPH and all EGTs rise. When the FF changes from one mag to the next we can’t draw conclusions about timing, and it’s hard to draw reliable conclusions about plugs. Here we can’t say for sure which mag is first – L or R – because all EGTs rise with the leaner FF, as you’d expect them to.

Let’s look at the sweeps around the 50 min mark. 6 peaks first, the others peak reasonably close together. 6 is the last to peak when richening again. CHT 6 is also high whenever EGT 6 is high – all indicators of a clog in injector 6.

Our test profile guidlines are to start about 100º rich of peak, then slowly lean with a steady rate of change until the onset of roughness, then reverse direction and richen back to where you started, then reverse and lean again, rinse, repeat…

Three sweeps like that is usually enough to draw meaningful conclusions. Let’s finish this month with a mixture sweep from a Beech Debonair with a Continental IO-520.

He got the slow part allright, once he got very lean – but it’s too fast before it’s slow. It goes from the high 15 GPH range to the low 12 GPH range in less than 15 seconds. Then it happens again in reverse as he richens. The rate of change around the peaks is what we use to calculate the spread.

It would have been fun to fly a big radial engine in 1955, experimenting with the new concept of LOP mixtures. But it would have involved a lot of guesswork and some trial and error. Fortunately, thanks to the efforts of John Deakin and the other advocates of the early 1990s, LOP got a new lease on life with new technology to support it, and has become a keystone of engine data analysis.