I saw the phrase “fueling speculation” in a political context this week and wondered how those two words became attached in our lexicon. Why didn’t “provoking” or “prompting” or “eliciting” catch on the way “fueling” did? Then I opened my first SavvyAnalysis chart of the day and found myself doing exactly that – speculating about fuel. (I think for my headline to work you have to change from a participle to a gerund, but I think poetic license permits that.)

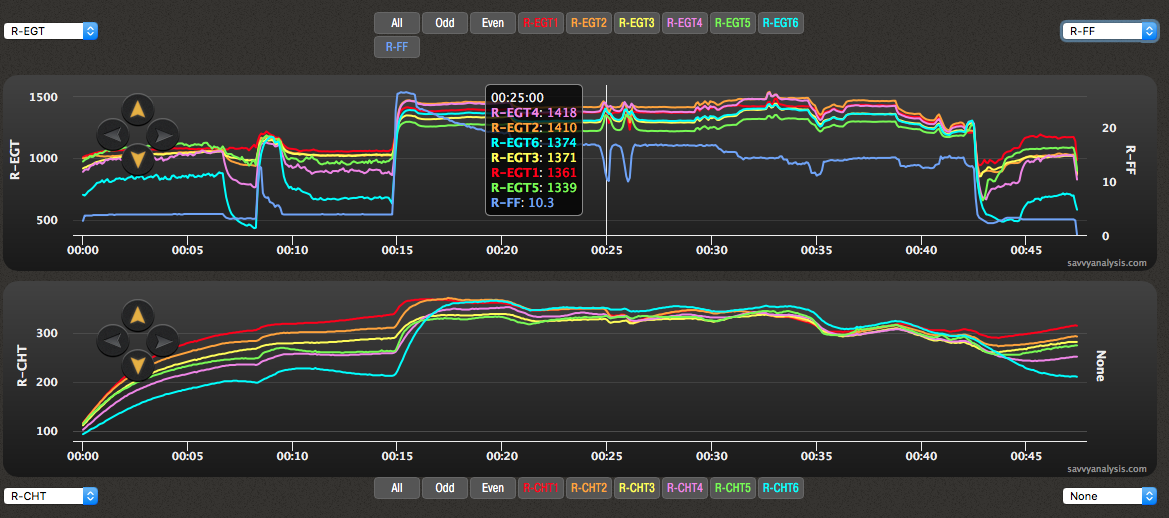

Here’s the scenario. A 1982 Beech Baron with IO-550-N engines had just completed a prebuy inspection which converted into an annual. Our client had submitted data from a post-annual Savvy Test Profile which showed good mixture distribution on one engine and horrible distribution on the other engine. Our benchmark for good distribution is a GAMI spread of 0.5 GPH or less, because that should allow smooth operation in cruise at about 50º LOP. His three L engine sweeps averaged 0.5 GPH. His three R engine sweeps averaged 3.1 GPH. Here’s a screenshot of the first mixture sweep on the R engine, with a spread of 3.4 GPH.

3.4 is higher than we see with carbureted engines and their notoriously poor mixture distribution. It was a real puzzle to know that these were GAMIjectors on both engines, but one side seemed correct and the other was, well – horrible isn’t too strong a word. Wouldn’t a mixture distribution this bad be reflected in abnormally high or low CHTs? Let’s take a look. Here’s the flight data with EGTs on top, CHTs on bottom and the cursor at the first sweep.

CHTs look surprisingly normal. CHTs 4 and 6 – purple and cyan – seem to corroborate the EGTs during ground ops, but no CHT shows a wild deviation from the pack in cruise – the kind you might expect with cylinders running much leaner or richer than they’re supposed to. So now we’ve crossed from evidence and observation to speculation. What’s in the realm of possibility? Could the fuel sensor be sending bogus data and the spread is really ok? A check with the client confirms that the R engine is rough, so despite decent-looking CHTs, something’s wrong with the distribution. Could this be a malfunction in the fuel spider? Is it possible that some or all of the GAMIjectors were installed into the wrong cylinders? It did just come out of annual and I’ve read enough Mike Busch articles to consider the possibility. Yeah, but this is a twin – and it really stretches the imagination to think that the injectors on the L engine went back into the correct holes and the ones on the R engine didn’t.

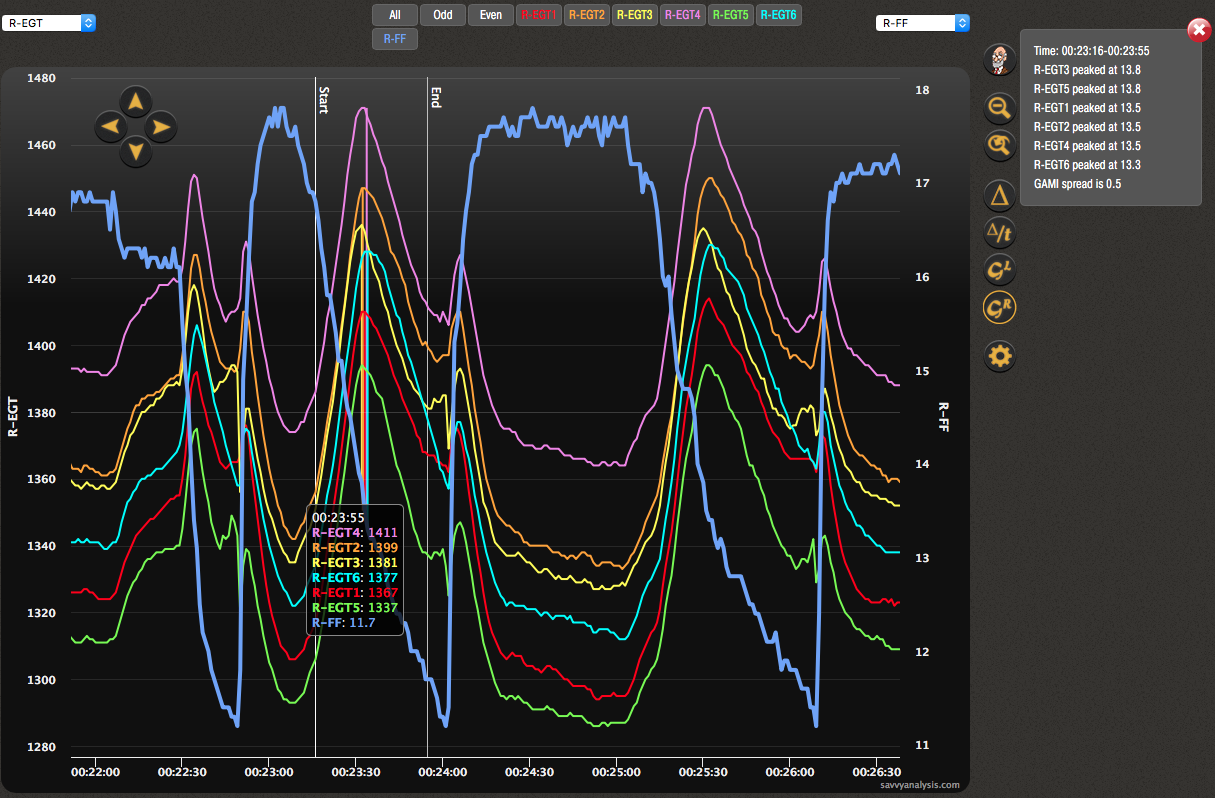

It seemed too remote a possibility to pursue but just about the time we were considering having our client check that, he posted a note to the ticket explaining that the A&P/IA had checked and that’s exactly what happened – the injectors had gone into the wrong cylinders. They were pretty sure that now they were correctly installed, and would we check the data now? Here’s the R engine with GAMIjectors fueling the correct cylinders, showing a spread of 0.5 GPH.

We don’t know how it happened, but while we’re fuel speculating – it might have been two different mechanics, or one mechanic becoming distracted, or haste, or maybe just dumb luck that the injectors on the L side went in the correct holes. GAMIjectors ship with a small plate which has a number stamped into it, and that is epoxied onto the valve cover as part of the installation. Match the numbers, and all’s well – or at least should be. A while back we had a Savvy Maintenance client who had some cylinder work done and the valve covers got re-installed on different cylinders. You’re way ahead of me – yes, the GAMIjectors then also got installed on those different cylinders.

So while the data can’t determine the cause of random maintenance acts like these, it did help isolate the cause of the rough running to the fuel system, and to the mixture distribution – which is a big improvement over the days when we would taxi up to the shop and offer nothing more than “she’s not running right.”

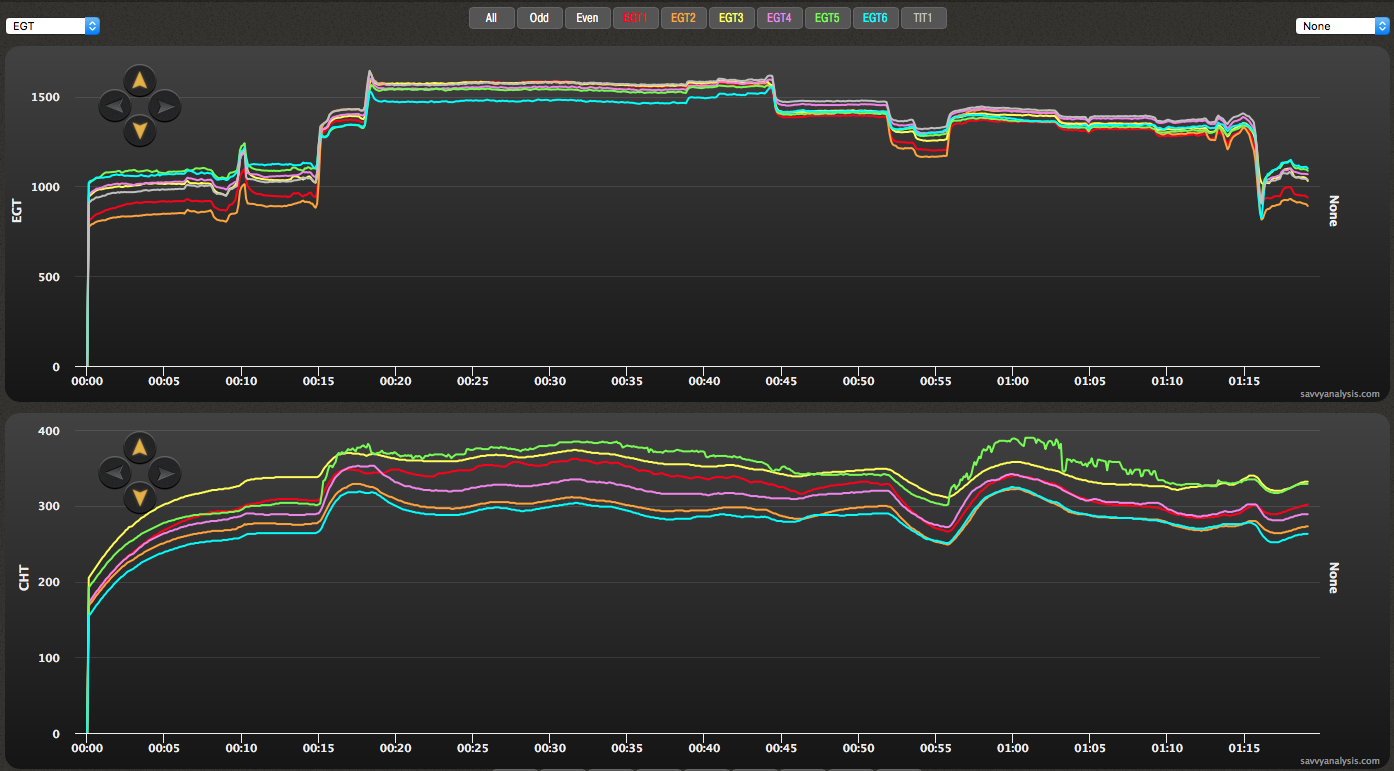

That last one, I admit, was a puzzle with a very improbable solution. Let’s finish this month with an easier one. Here’s data from a 2005 Cessna 400 Corvalis with a TSIO-550-C. The bold blue line on top is Fuel Flow, the bold light blue line on bottom is Manifold Pressure. I could have displayed Oil Temp or other parameters but there are no more clues in those traces than in FF or MAP.

There’s an erratic pattern in CHT 5 – the green trace. It’s most erratic in climb, but still wobbly in cruise, and pretty much all the way to short final. There’s no corroboration of uneven combustion in the trace for EGT 5, so this doesn’t appear to be connected to fuel or ignition. Do we trust the CHT 5 data? Could it be a failing CHT probe? Could it be a cooling issue – maybe a loose baffle? Let’s look at the next most recent flight.

CHT 5 seems normal until takeoff, then starts its pattern. Again, it seems loosely tied to power settings. We’ve seen probes fail like this – un-spectacularly, without a lot of fanfare. So we can’t rule that out, but if we decide to trust the data, what would cause this type of pattern in CHT? Baffle and baffle seal anomalies come in many shapes and sizes, too, and often track with power settings, so we can’t rule that out yet, either. There might be a clue in the fact that when the engine starts on the most recent flight — the one with the FF and MAP overlays — CHT 5 is already making more heat than the others.

So what are the clues? Extra heat in the cylinder, uncorroborated by EGT, random changes in the pattern under one power setting, and often a visible change in the frequency of the pattern with a change in power setting. We don’t have a huge repository of engine data with known broken piston rings, but the ones we have are similar to this. Our recommendation was to check the connection, and if that checked out ok, to consider swapping with an adjacent CHT probe. We always recommend borescoping cylinders at annual, and since this annual was approaching, we suggested a good look at the #5 barrel – especially the ring lands.

During the inspection, the #5 barrel had scuff marks and scratches as a result of a broken compression ring. In this case, it hadn’t logged enough time since the ring failure (which appears to be on the takeoff roll of that earlier flight at the 15 minute mark) to result in increased oil consumption or fouled plugs. The compression test should have revealed it, but the engine data gave the first clue.