It’s one of the great lines from a movie filled with great lines. Wallace Shawn was the perfect actor to deliver it, and now it’s hard to say the word without putting his unique cartoon-like spin on it. And now a quick pivot to engine data. Sometimes the numbers will suggest a scenario that’s improbable, or unlikely or far-fetched. Sometime’s it’s a step beyond that and downright – Wallace, your line please…

We had one of those recently. The electrical system was normal during ground ops and the initial takeoff roll. As the plane reached rotation speed, the alternator dropped off. We rounded up the usual suspects. It wasn’t the gear switch. Or the squat switch. It wasn’t the angle of attack. It wasn’t RPMs. Or a loose alternator belt. Or a loose motor mount. Or a broken alternator bracket. What’s left? Must be the voltage regulator, or the over-voltage really? Nope. All good theories but there was an excellent correlation with one particular logged parameter that led to the solution.

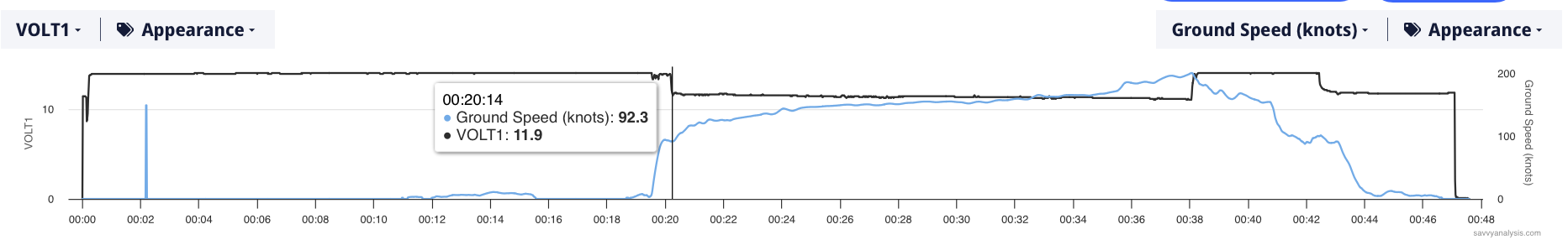

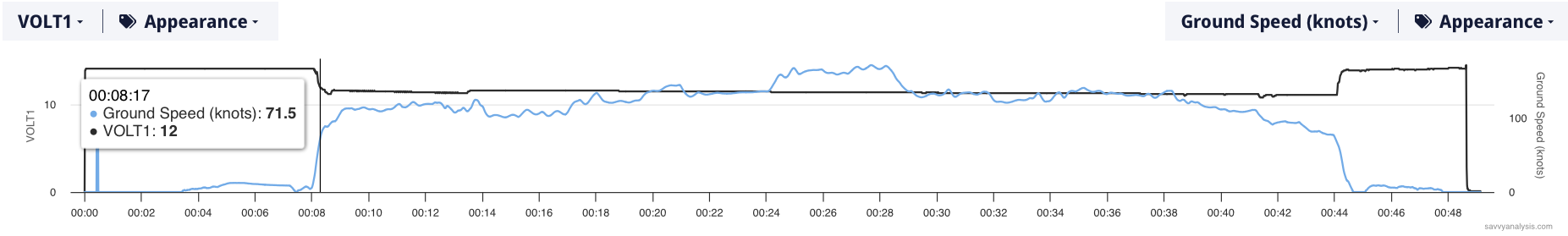

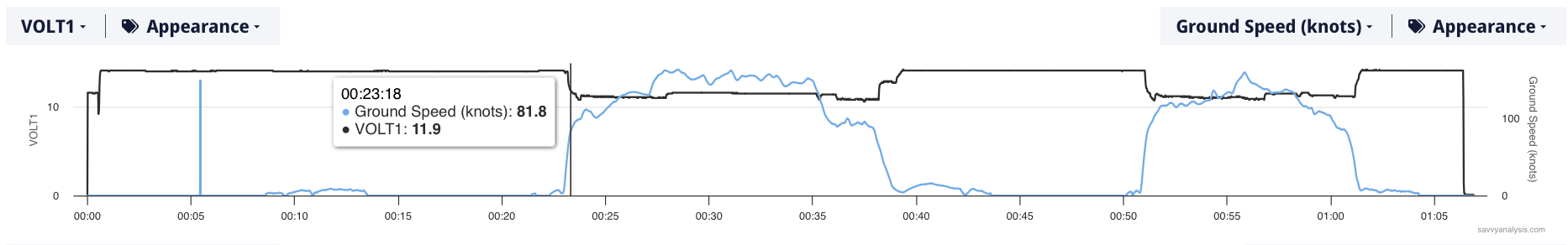

The owner of the Bellanca Viking spotted it. Bus voltage was dropping from about 14 to below 12 in the takeoff roll. And not a slow drift down – more like a switch being flipped. Here are some examples. Volts in black and groundspeed in blue.

Data tells us that sometime around 80 knots ± 10 is when the voltage drops. The owner reported that it didn’t matter if the airplane had rotated or was still accelerating on the ground. That shot down any connection to the landing gear in transit. The owner also reported that when the airplane landed the voltage went back up and you can see that in each of these charts. It happens twice in the third chart. The shop was ready to replace parts. The alternator, alternator bracket, voltage regulator, and voltage relay were all discussed.

The owner just kept coming back to this correlation with speed. Especially the voltage jump back to normal as speed dropped. He convinced the shop to concentrate on cables and to hold off on ordering parts. The shop pulled the cables and on one of them found a very fragile connection under the insulation. There was enough wire to conduct the load until the incoming air moved it slightly then it failed. And when the air stopped, it was fine again.

I’ve been looking at data for a while now, and I don’t ever remember graphing voltage and ground speed before. But in this case that’s where the answer was hiding.

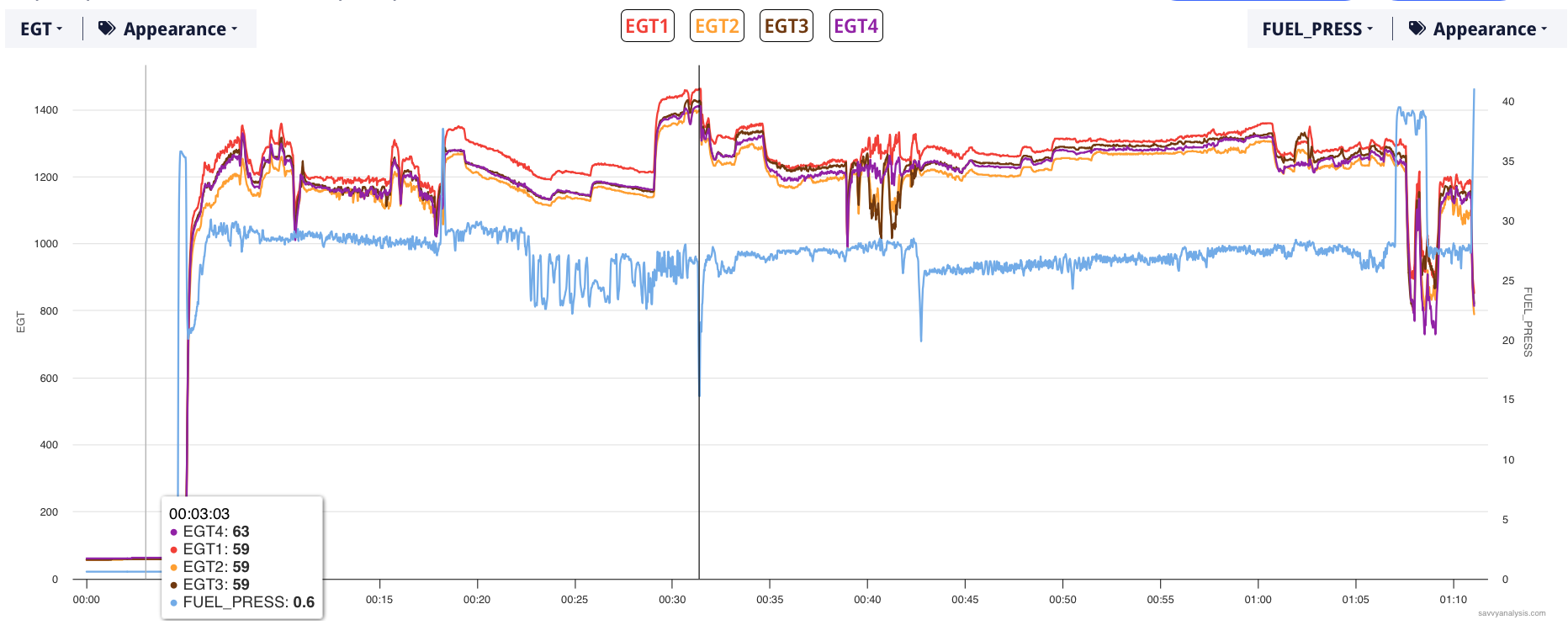

Next is an RV-14 powered by a Lycoming IO-390 and data from a Garmin G3X with a 1 sec sample rate. The owner reported occasional engine coughing during climbs. And pointed us to this drop in fuel pressure which he described as a hesitation. The cursor is on the event at the 31 min mark – ignore the number block off to the left out of the way so it doesn’t cover up the EGT traces.

So we’ve got fluctuating fuel pressure at 22 mins until the event at 31 mins, then it’s steady even as EGTs jump around at 40 mins. That’s a troubleshooting mag check because the engine wasn’t as smooth as it had been in the past. But fuel pressure is steady there.

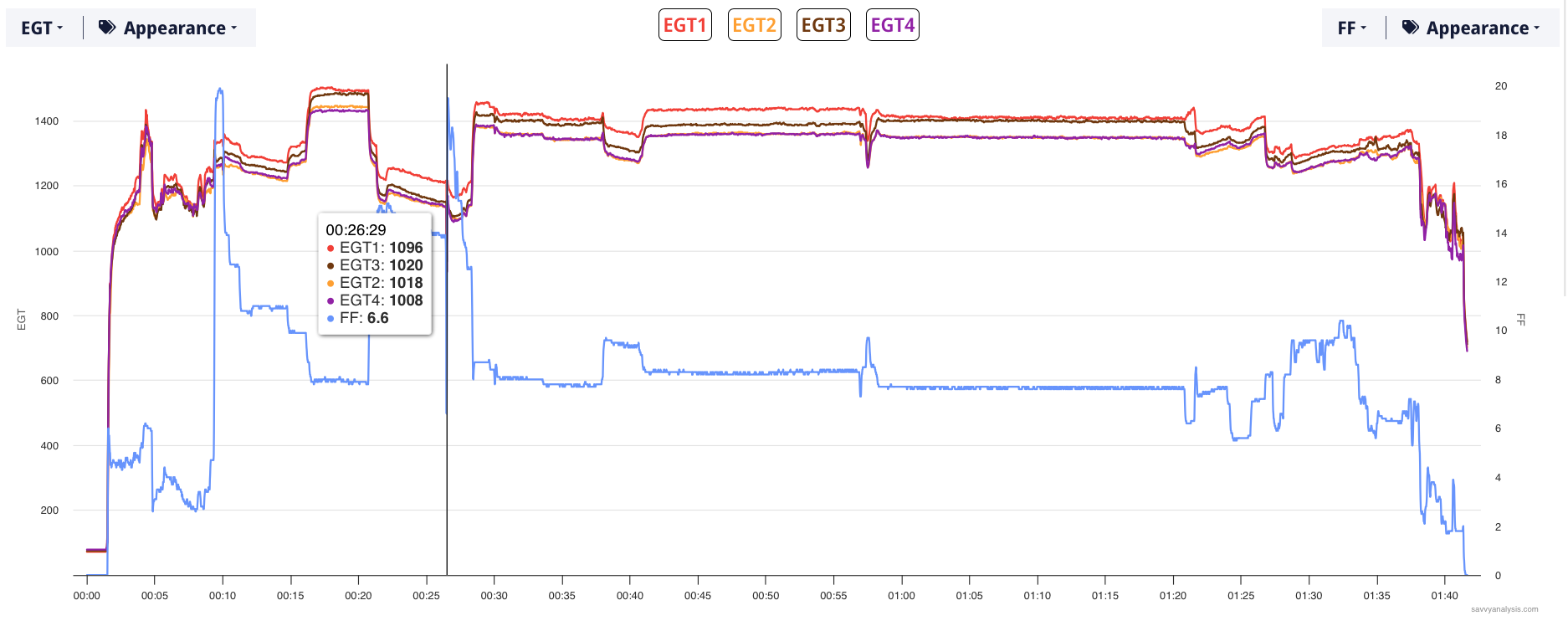

This airplane uses a PMAG so we had to be sure that it was properly calibrated. And that the correct plugs and harness were in place. All good there. Then we got data for this flight, showing another event with an uncommanded drop in FF to 6.6 GPH.

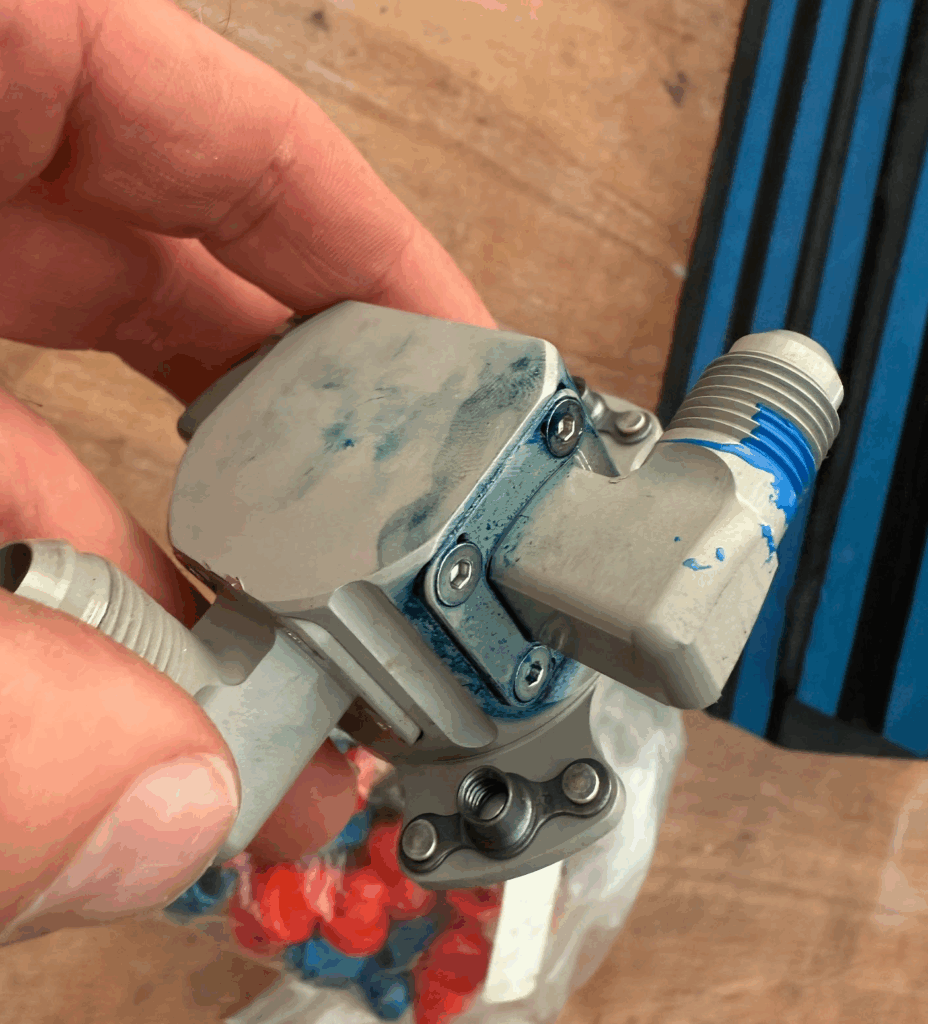

Now it’s starting to look less like a combustion event and more like a fuel deprivation scenario. It’s a fairly new engine, so failure of the mechanical fuel pump seemed unlikely. My colleague Ray – who built and flies an RV7 – suggested checking the valves and fittings starting at the fuel pump and working aft toward the fuel supply. We had just had a ticket from an RV8 with loose fuel line fittings. The RV14 client started his inspection and found this.

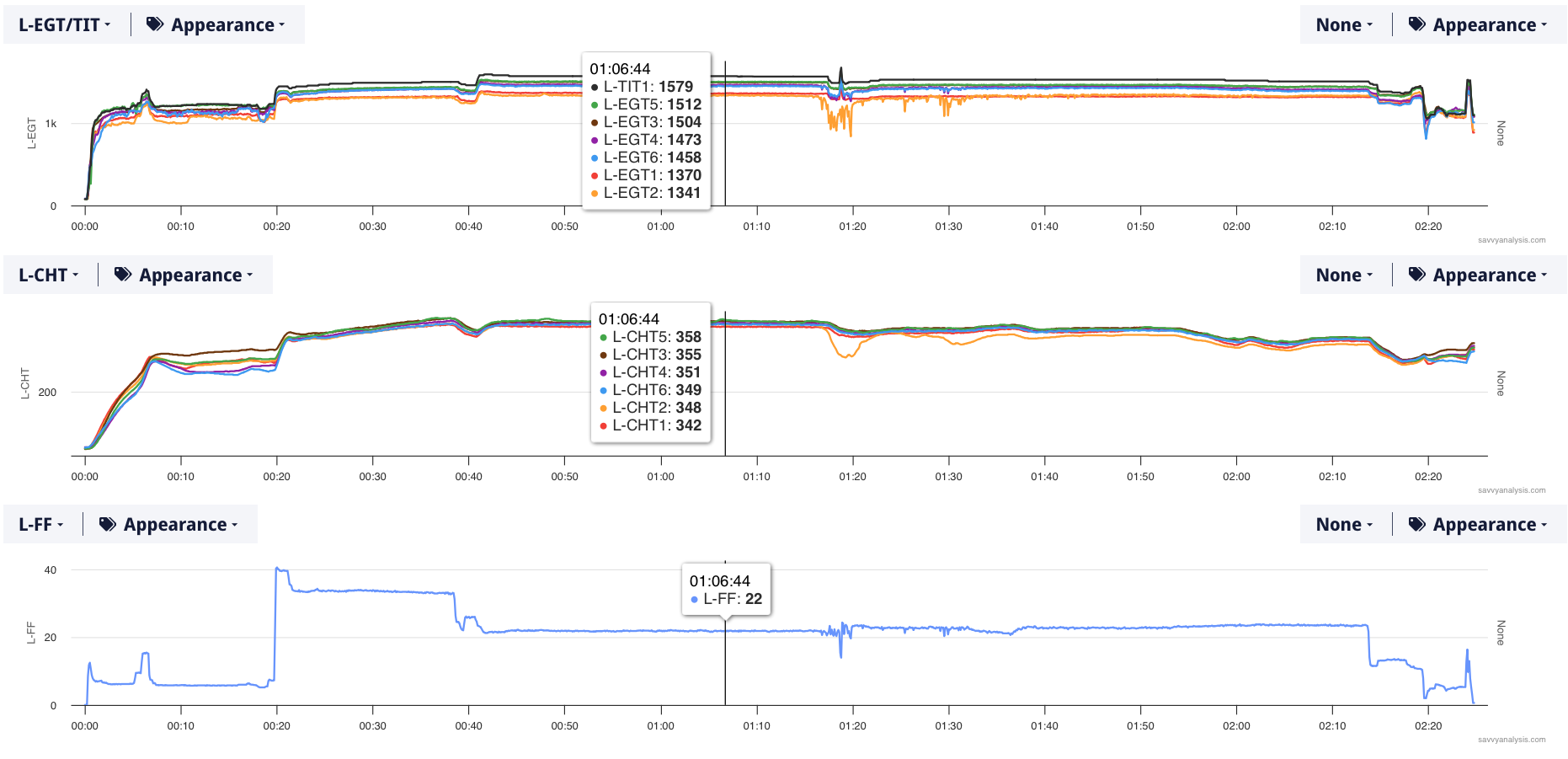

Next is an Aerostar powered by Lycoming TIO-540 engines and data from a JPI 960 with a 1 sec sample rate. The owner reported rough running during an enroute climb. Altitude isn’t logged but it was easy to spot.

It doesn’t look like a typical spark plug misfire. Typically when one plug drops off the EGT will rise and that’s not happening here. There’s enough of a drop in power to cause CHT2 to drop for a while. And there’s a disturbance in fuel flow, which we wouldn’t see with a simple plug malfunction. This had more symptoms of a sticky valve than a misfire. The owner posted two photos. The left is the harness for the top plug of cyl 2. The right is the harness for the bottom plug of cyl 2. The break was hidden under an Adel clamp.

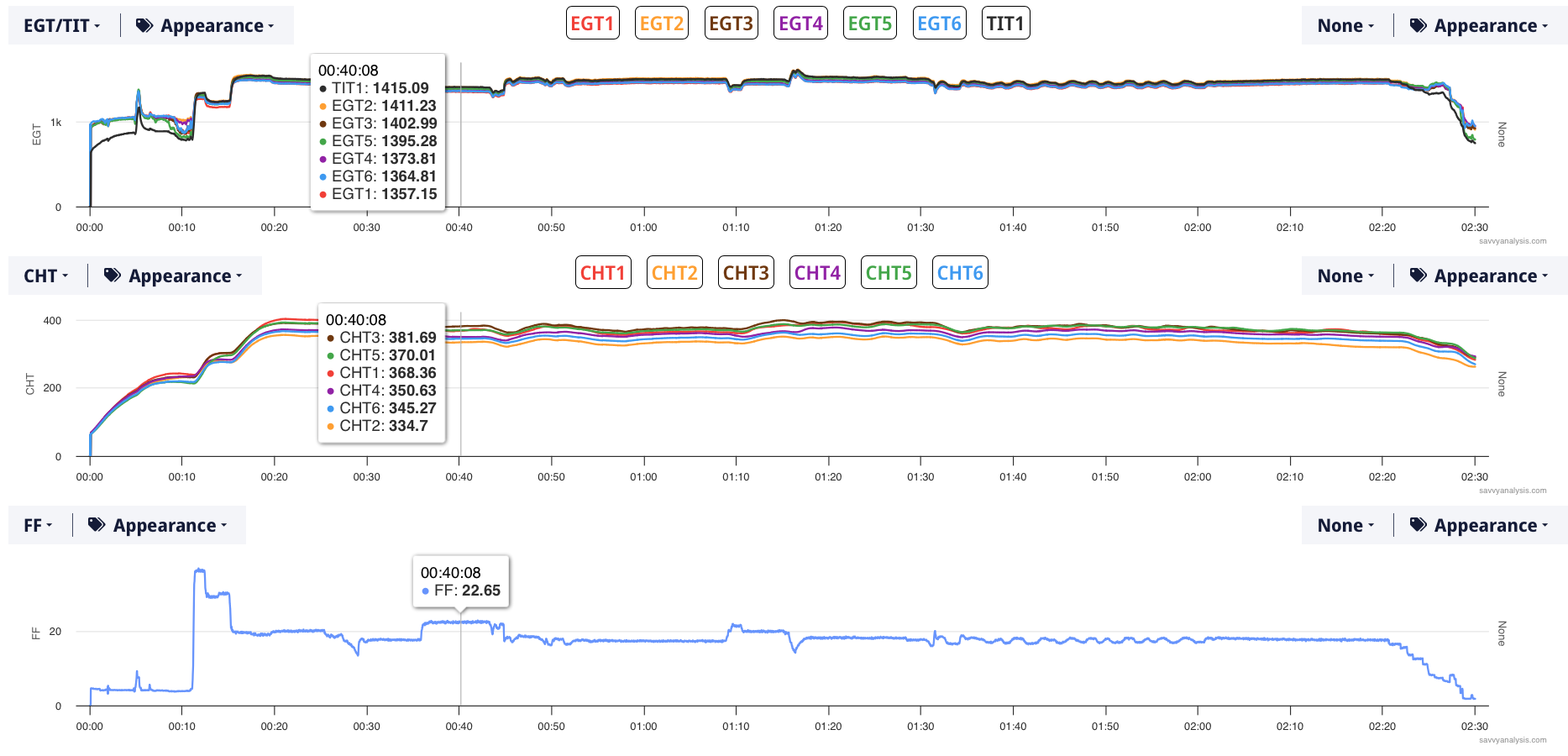

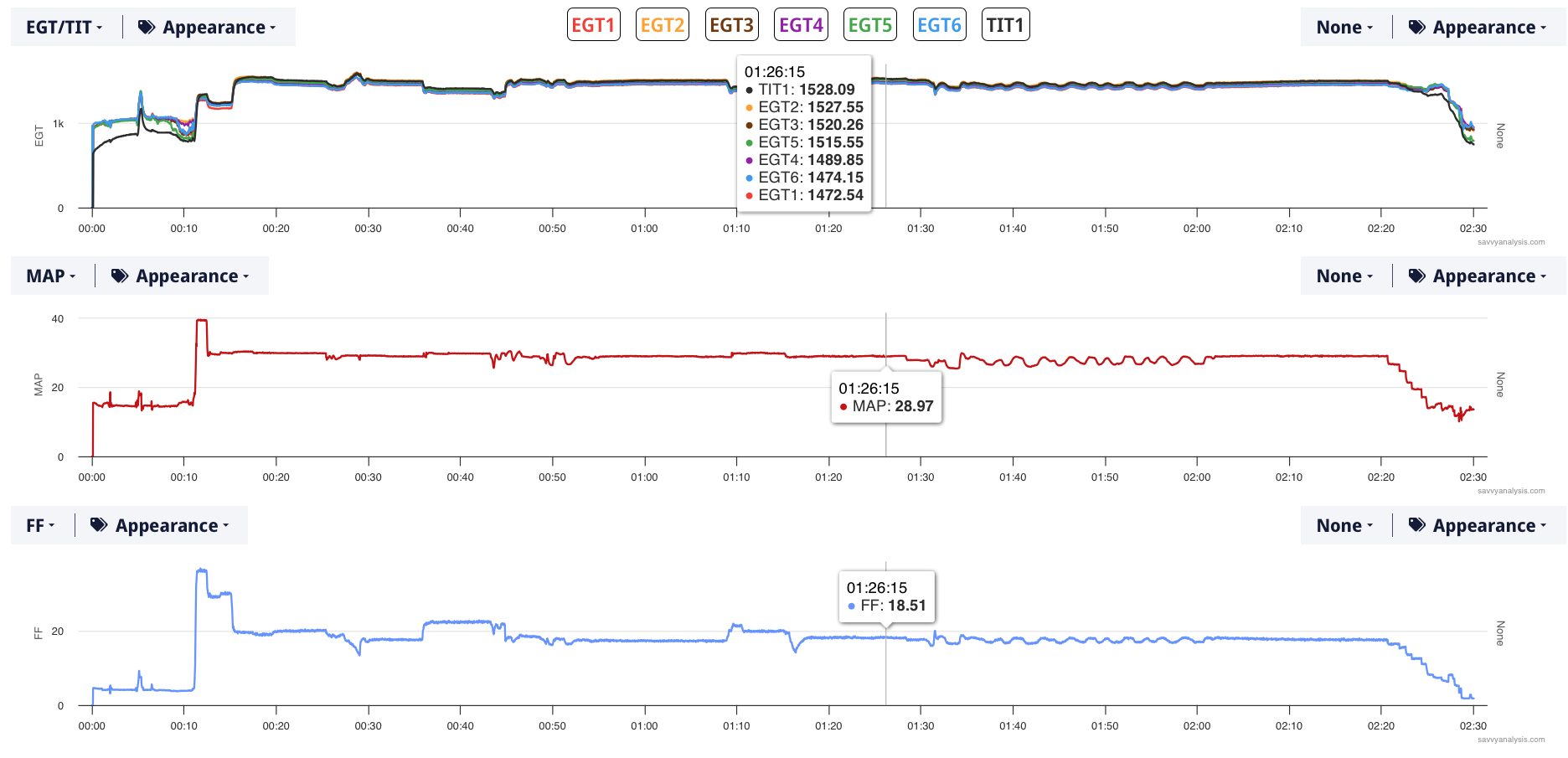

We’ll finish this month with a Cessna T206 powered by a Lycoming TIO-540 and data from a Garmin G1000 with a 1 sec sample rate. The owner reported – – “the turbo would not hold MP @ 14500ft, 23″/2300RPM – @ 2300 RPM, MP would vary from 25+ to 30″. Bumping the RPM to 2400 seemed to alleviate the issue.” Let’s look at EGTs, CHT and FF.

It’s a little more complicated than “wouldn’t hold MAP..” Let’s look at MAP.

They’re all oscillating together. It doesn’t seem like a stuck wastegate would have this pattern. It would go there and stay there. Or be more random with its moves. This looks like pressure building then venting, sending the turbo controller higher and lower. Could it be an exhaust leak? It could.

It’s a beautiful crack – if there is such a thing. Right where you’d expect it to be.

It’s worth noting that the airplane flew for an hour and a half before these symptoms showed up. And in terms of EGTs and CHTs, it doesn’t look like powerplant mismanagement is to blame.Temps and TIT are benign.