Recently I saw an ad for a furniture store encouraging me to “kickback in style”. I remember hearing that word a lot as a term for relaxation when I moved to southern California in the early 80s. Before moving, I had read that word a lot in the Chicago papers in regards to unscrupulous public servants. And years before that, it was what my Royal Enfield 750 liked to do on cold mornings. In the world of aviation, we usually hear it in regards to starters – and it’s usually not good news.

Usually engine starts happen before the avionics bus goes to ON and before the engine data monitor starts logging – which is why you’ll rarely see engine starts as a topic in this column. But I do have a good one for you. Recently Savvy account manager Dean Showalter discussed a problematic engine start event that resulted in a cracked starter housing on his Airplane Owner Maintenance podcast. Dean and I worked together on a ticket for a 172, and that’s where we’ll start this year’s set of puzzles.

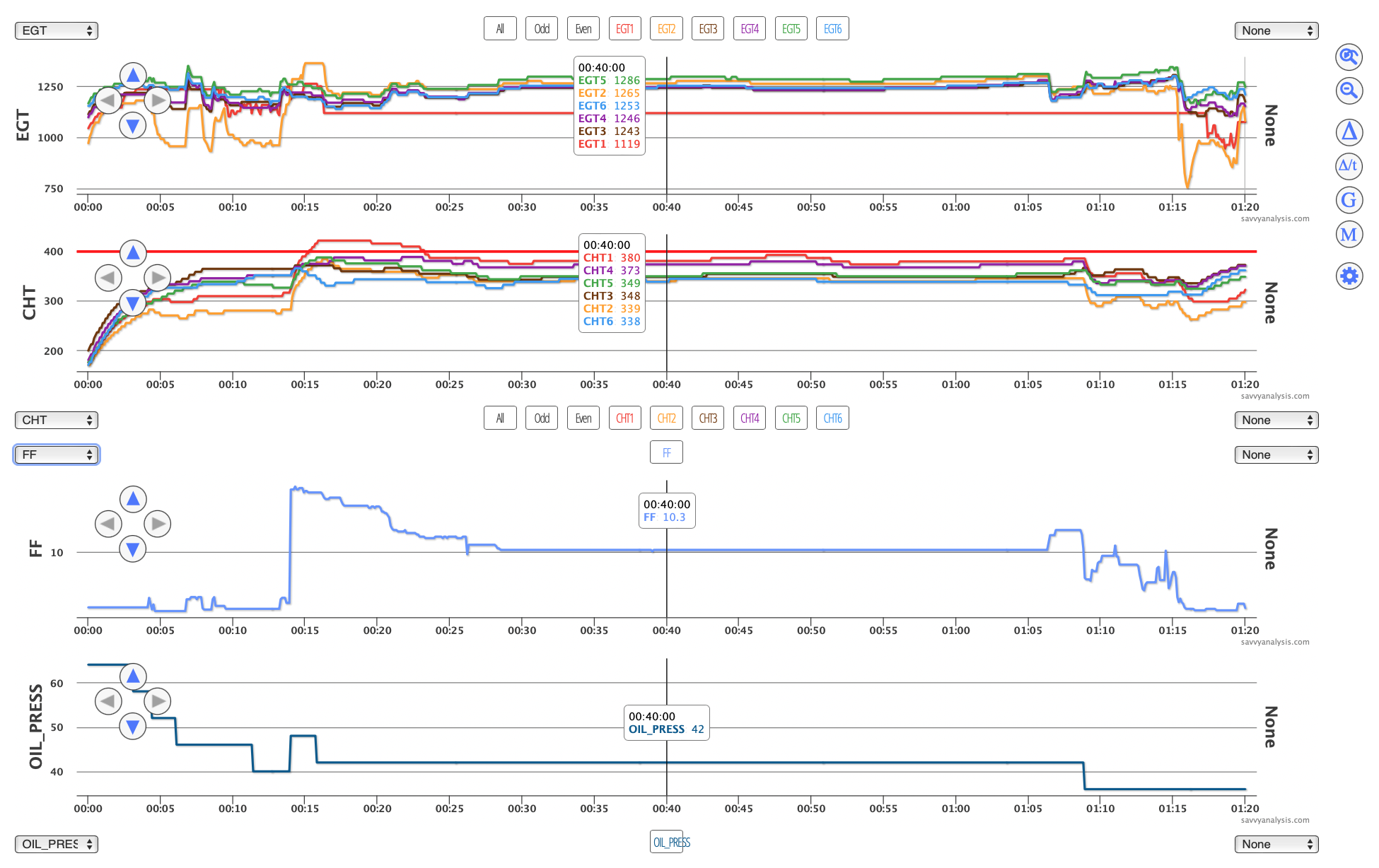

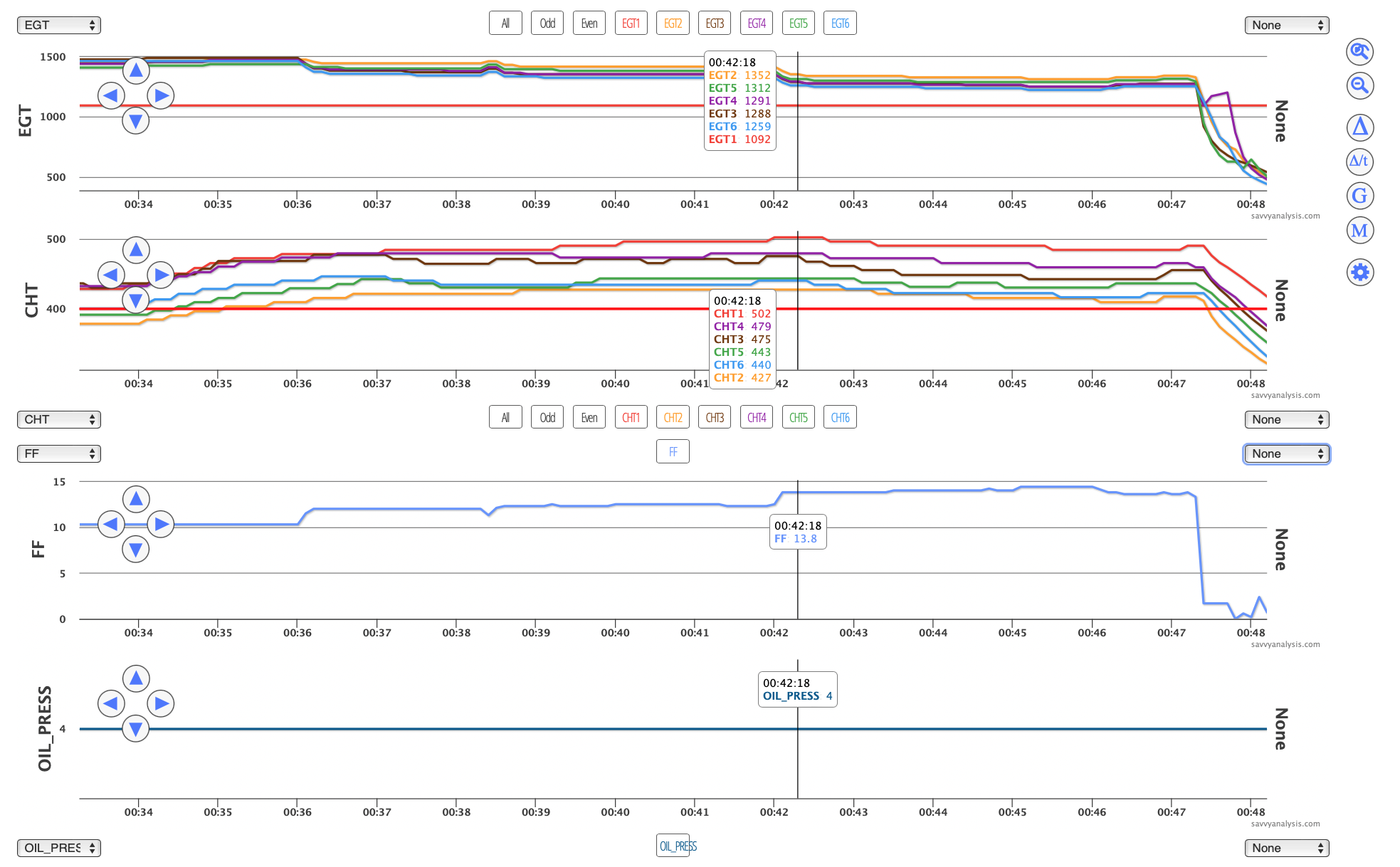

First up is data from a Cessna R172K Hawk XP with a Continental IO-360 and data from a JPI 830 with a 6 sec sample rate. EGTs on top, then CHTs, FF and oil pressure. This is an uneventful 1:20 flight before any problems set in just so you can see what “normal” is for this plane.

EGT and CHT for cyl 2 are low at idle which could be a weak valve spring – not really acting like weak spark or fuel or induction. Cyl 2 looks ok in cruise, though. EGT 1 flatlines during the climb then tracks again after landing. That could be the probe, but it always makes sense to check the connection first. But the value of this data in our analysis was that oil pressure started at 60-something, then settled in at 42 in cruise. Then a group of pilots takes the airplane on a cross-country trip, and here’s one of those flights.

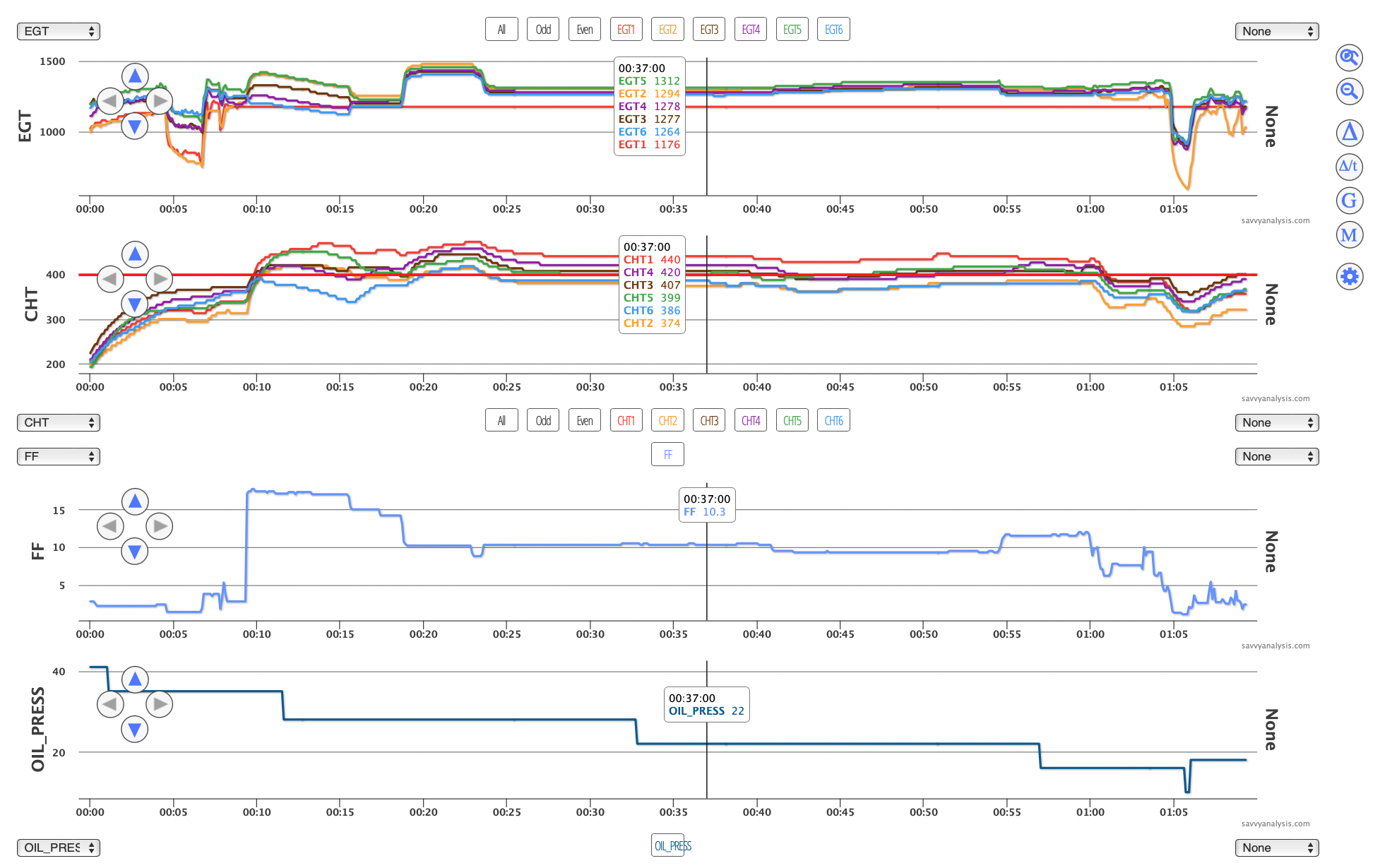

Oil pressure was 60+ at engine start in the reference flight, and is now 40+. Was 42 in cruise, is now 28 then drops to 22. CHTs are 40-60º higher with identical fuel flow of 10.3 GPH. They stop and refuel, and here’s the next leg.

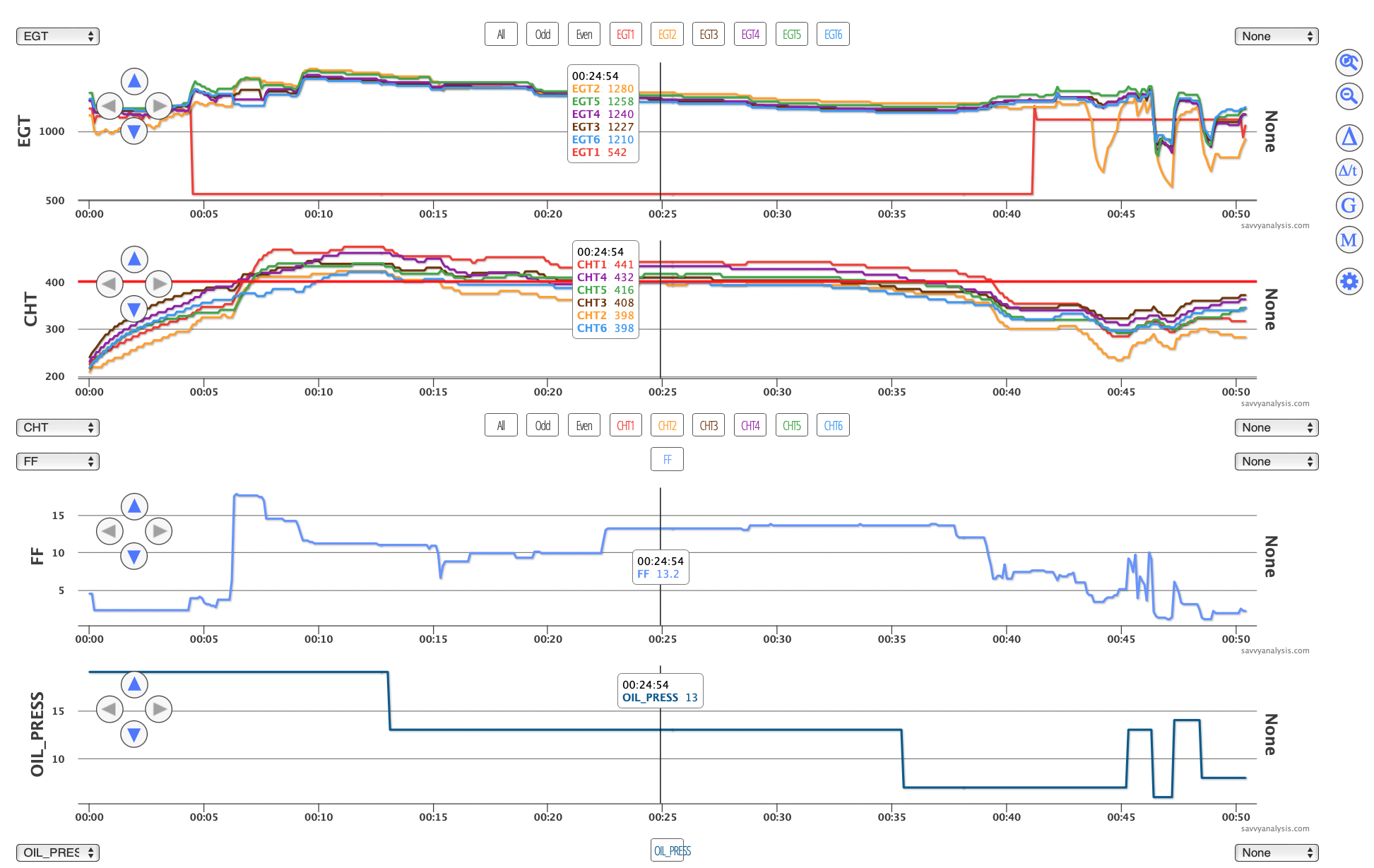

Oil pressure is now about 20 at takeoff and 13 in cruise. EGT 1 stops tracking. The CHTs which were on the cool side are now hotter, but cyl 1 – the hottest – is just barely hotter. The trip continues.

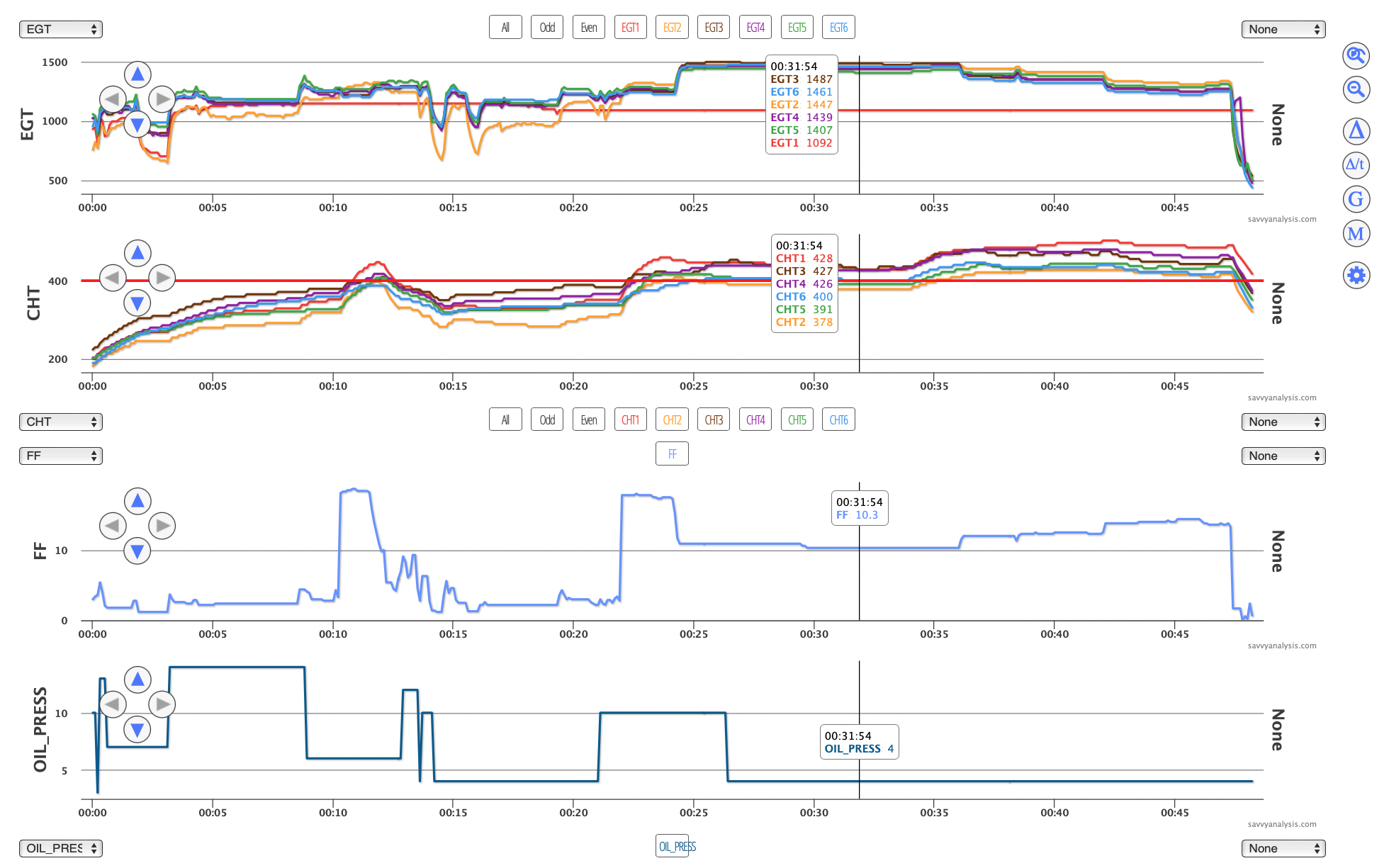

This one looks like they took off, changed their mind, came back and landed, then decided to take off again. EGTs are now much higher in cruise with the same fuel flow. CHTs are – surprisingly – slightly cooler than the previous flight. CHT rise at the 35 min mark. Here’s the end of the flight starting with the CHT rise.

At this point, adding more FF doesn’t really help cooling. It brings EGTs down a little, but all six CHTs are 427+. Finally, at 47:18 the engine seizes, and the plane makes an emergency landing in a field. No damage to the pilot, passengers and airframe. The engine, on the other hand, was toast. This is five shots of cylinder 1, plus the oil suction screen.

You probably noticed I haven’t said a word about oil temp. There isn’t much to say. I didn’t depict it because it was in the 160-195º range through all these flights.

Wings were removed and the airplane was trailered to the shop where Dean works. Here’s his report.

I went to the airport this morning, on my day off, with great anticipation of removing that number one cylinder we’ve been talking about… It turned into a very disappointing situation, when I got everything removed and all the cylinder base nuts off, and I just could not pull the cylinder from the crank case. Something is terribly bound up in there. It was difficult to get a good picture of the intake valve, but it looks like it is bent and stuck open. Also, the exhaust pushrod was a couple inches down inside the tube… And the lifter was nowhere to be found. I guess the engine ate it. Down inside the bore for the exhaust lifter, the case has large cracks in it. Absolutely incredible that the engine did not come apart worse than this.

I removed the oil sump and found a load of stuff in there… the exhaust lifter is actually in good condition… the pieces of the #1 connecting rod that was attached to the crankshaft journal were all beat up… and the crank journal itself looks severely worn.

Some mechanical questions come to mind. Why did cylinder 1 fail? Even when oil pressure was good, CHT 1 was higher than we like to see. The intermittent then unreliable EGT 1 data can’t help us determine whether the high CHT was from a fuel issue or a cooling issue. It’s a Continental so 1 is in the back, and the oil cooler is behind cyl 2 on the other side. And the one nagging question is why did this group of pilots continue the trip as oil pressure continued to deteriorate? Thanks to Dean for the info and great pictures on this one.

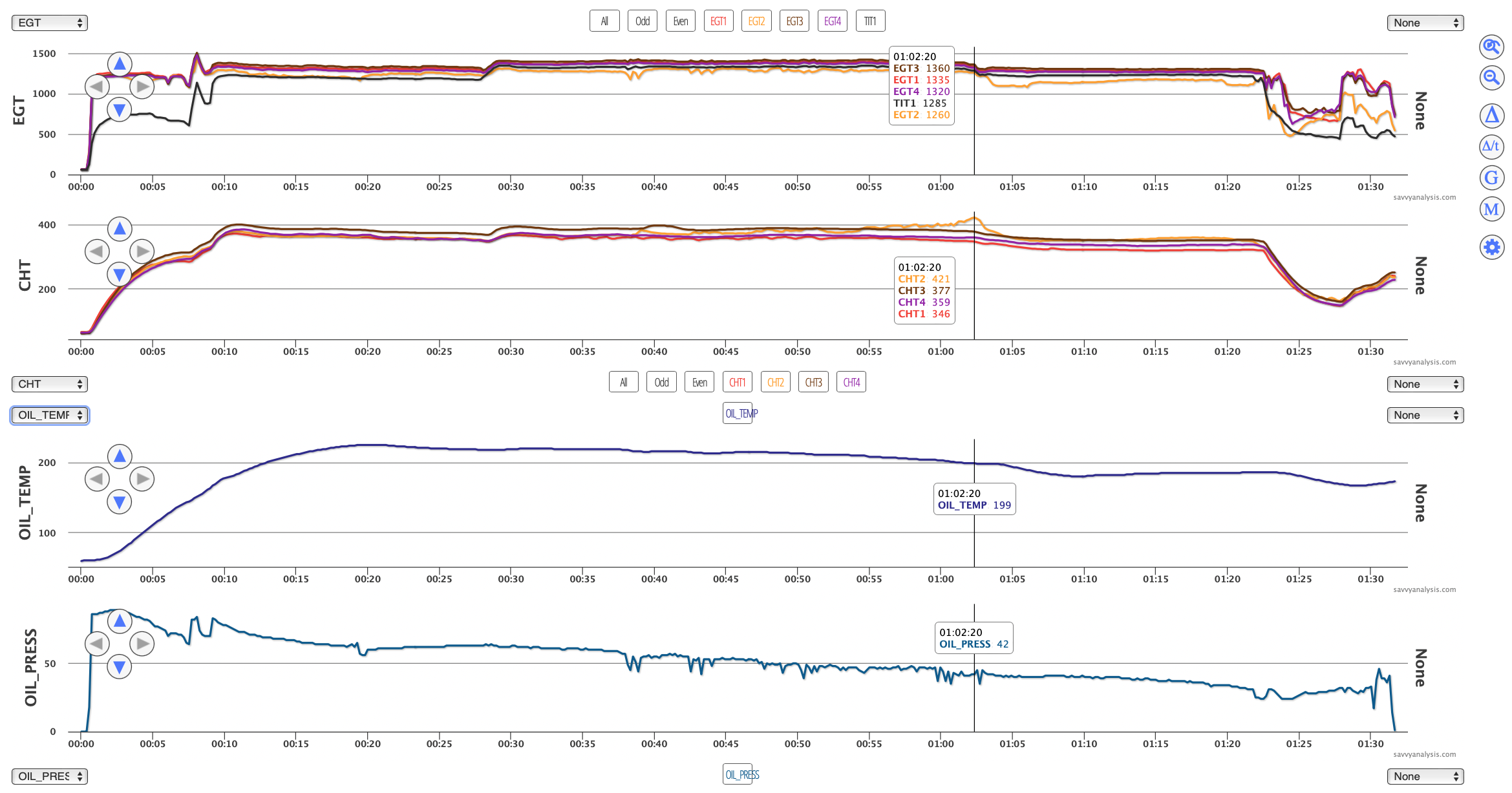

Next up is data from a Mooney 20F with a Lycoming IO-360 and a Rajay turbo normalizer. Also uses a SureFly ignition on left mag. Data is from a Garmin G3X with a 1 sec sample rate. EGTs on top, then CHTs, oil temp and oil pressure.

Starting our analysis with EGTs, #2 moves around in the climb, then develops some sawtooth-shaped patterns. It’s tempting to dismiss those patterns as a loose EGT connection, except that oil pressure shows nearly identical moves. Oil pressure starts out ok – it’s about 90 at engine start then drops a little and rises to 83 at takeoff. Then it settles in around 65 until the sawtooth moves at 38 mins, and begins a drop which continues until short final. CHTs – each one has something to say. 3 is high throughout and has a little excursion at the 40 min mark. 4 has a slight wavy pattern in climb then settles down. 1 is ok in climb, then has a wavy pattern with the higher speeds of cruise. 2 is ok in climb and early cruise, then starts a slow gradual rise when the EGT 2 and oil pressure pattern begins, peaking at 421º where the cursor sits.

So far we know that somethings going on with oil pressure and with cyl 2 – and they appear to have a high correlation coefficient. That event at the cursor might have been a short detonation event – FF is not depicted but rises there from the 10 range to the 13 range and stops CHT 2 from rising. All EGTs drop but 2 drops a lot. And oil temp is dropping – not that that’s a problem in itself but combined with the continued drop in oil pressure is not comforting. It’s in this timeframe that the pilot starts thinking about stopping short of his destination a few more hours away.

About 20 minutes ago he had overflown a familiar airport, so he decides to turn around and go back there. It’s running rougher now, so he decides to stay at 8500 MSL until he’s within gliding distance of the field. Then he chops the power at 01:22 and puts it on the ground.

Subsequent inspection revealed that the engine lost 4 quarts of oil during this flight, and that the oil wiper rings of cyl 2 were shattered. Fortunately no metal chunks made their way into the case. If we assume that those rings were ok at the beginning of the flight (and earlier data suggests there’s no reason not to assume that), then it took about 30 minutes under power to trash them.

Cylinder 2 was replaced and the engine is running great again.