Knock knock. Who’s there? An intermittent knocking sound that only happens in certain flight configurations and is probably not a safety of flight issue but could become one because it’s distracting the pilot from his primary job of “aviate.” Not to mention “navigate and communicate.” Wait – that’s not funny. You’re right. Nothing funny about it.

Remember that bumper sticker “I love airplane noise “? The P 51, the Ford Trimotor, the Rare Bear turning that giant prop at low RPMs- those are my favorites. You probably have your own. I love the sound of the cockpit of my Bellanca Viking, but only with a good set of ANR headsets. So while there are happy airplane sounds, there are some sounds we hear when flying that can distract us and maybe force a change of plans. And maybe generate some unpleasant sounds from the owner as the troubleshooting bills pile up. We have a couple examples this month as we take a look at data from a Piper Cherokee, a Glasair Sportsman, a Cessna 182 and a Cirrus SR22.

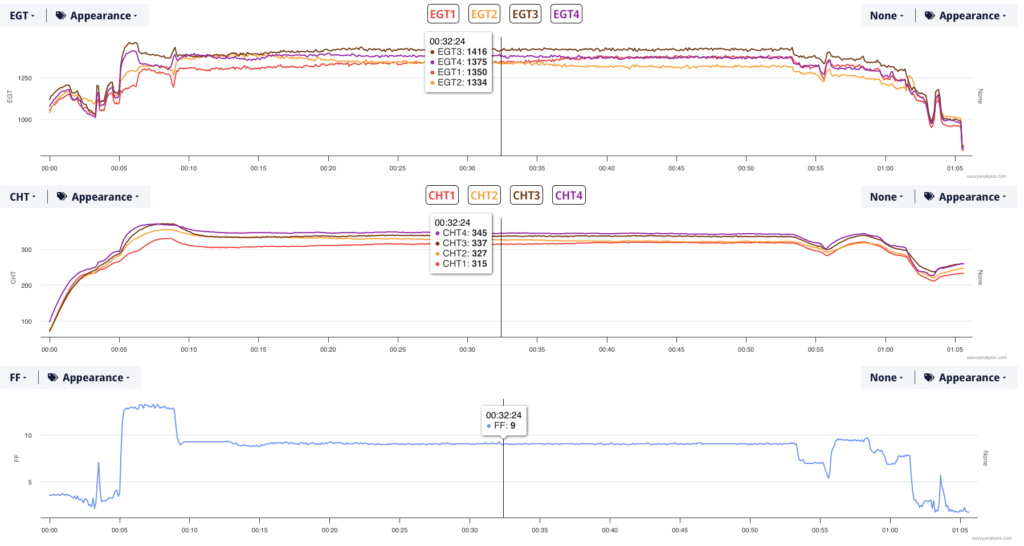

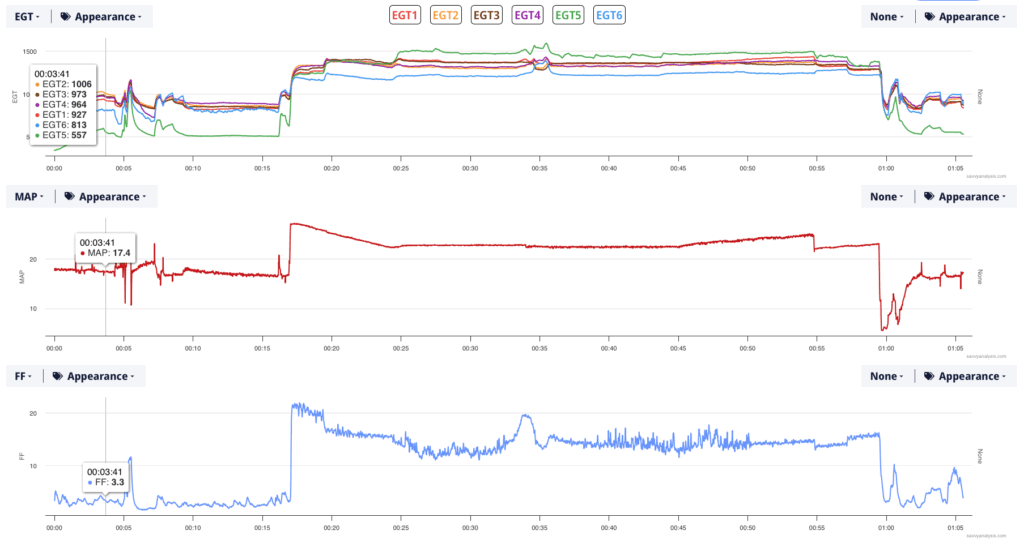

First up is a vintage Piper Cherokee powered by a Lycoming IO-320 (not a typo – the IO replaced the original carbureted engine) and data from a JPI 900 with a 6 second sample rate. Here’s data from a typical flight last December using my default display of EGTs, CHTs and FF.

The client reported that he heard a tapping or knocking sound early in the takeoff roll. Didn’t hear it during taxiing and didn’t hear it in the air. He attached a video and a couple of us listened to it and did hear a tapping sound where he said it would be. Let’s zoom in to early in the takeoff roll.

We looked through the takeoff rolls for several flights and didn’t see anything unusual in the data. It didn’t sound like the engine was sputtering or misfiring so we weren’t surprised to see smooth traces. We did notice that oil temperature was in the low 100s for a few of these takeoffs and asked our client if he thought the problem was seasonal. Did it happen more in the winter, or less? He said he heard it year-round.

When the data doesn’t point you to a solution, imagination takes over. Could this be a muffler cone that moved when power was applied and it got over a certain temperature? Fuel sloshes around when takeoff power is applied. Is this tied to that? Why would it only happen during the takeoff roll? Or maybe it was happening during cruise but getting buried in the noise floor. We were knee deep in speculation when our client posted “I found the noise , the metal defroster deflectors on the glare shield were tapping on the wind screen causing the metallic sound.”

Not at all what we expected but happy it was resolved with no wrenches leaving the toolbox.

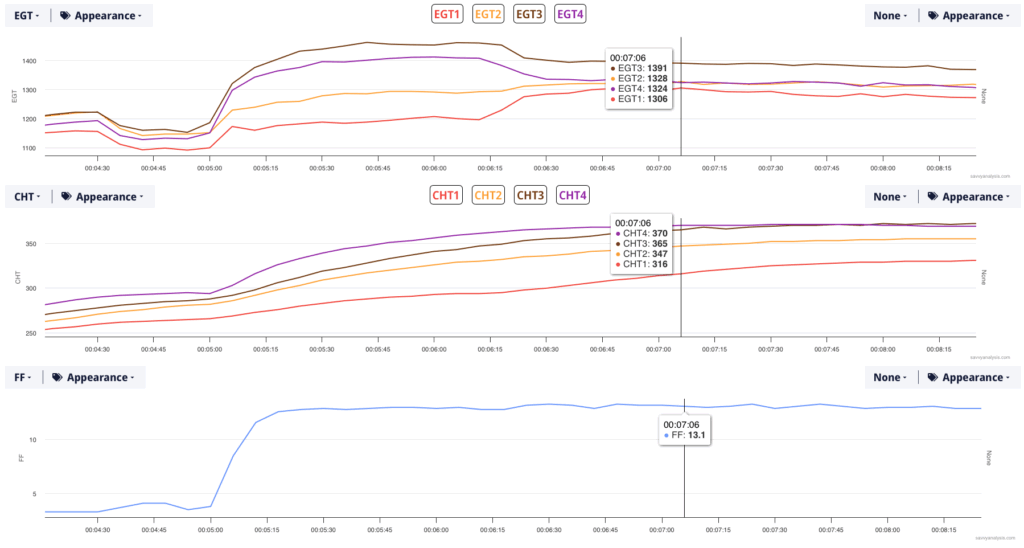

Next is a Glasair Sportsman 2+2 powered by a Lycoming YIO-390-EXP and data from an Advanced Flight Systems AF-3500 with a 5 second sample rate. This request came in as part of a pre-buy exam. The mindset is a little different with pre-buy analysis. In the typical owner scenario, we’re trying to help our client resolve the issue quickly and with minimal expense. With a pre-buy, our client the prospective buyer has the option of walking away and letting somebody else resolve the issue. Here’s a Puzzler devoted to analysis for pre-buy exams. Here’s data from a typical recent flight.

We also had a set of borescope pictures which showed a little bit of corrosion in the barrels but the valves looked good. We wondered why EGT 4 was low throughout – regardless of FF – and noted that the CHT 4 data was noisy. Those little moves aren’t actual changes in CHT, just noise in the data. And there are two little blips in the CHT traces around the 5 min mark that are not replicated in the EGT data.

Our client reported an intermittent “clunk” sound. in the various posts over a few weeks it became a “thud” and a “thunk.” We were surprised when our pre-buy client said that the noise and the blips in CHT didn’t line up time-wise. The drop in CHT didn’t really appear to be mechanical, but it was nice to be able to rule that out. This didn’t really have that sticky valve profile but couldn’t rule it out – and something was making that noise. We asked for test profile data and we got a set of mixture sweeps and an induction test, but the seller would not allow an in-flight mag check.

The sweeps showed good mixture distribution and that EGT 4 was not low because it was a lean or rich outlier. The induction test supported that 4 was not low because of a leak. Bottom line is we didn’t see any dealbreakers in the engine data and the noise was intermittent backfires which we didn’t see in the data because of the 5 second sample rate.

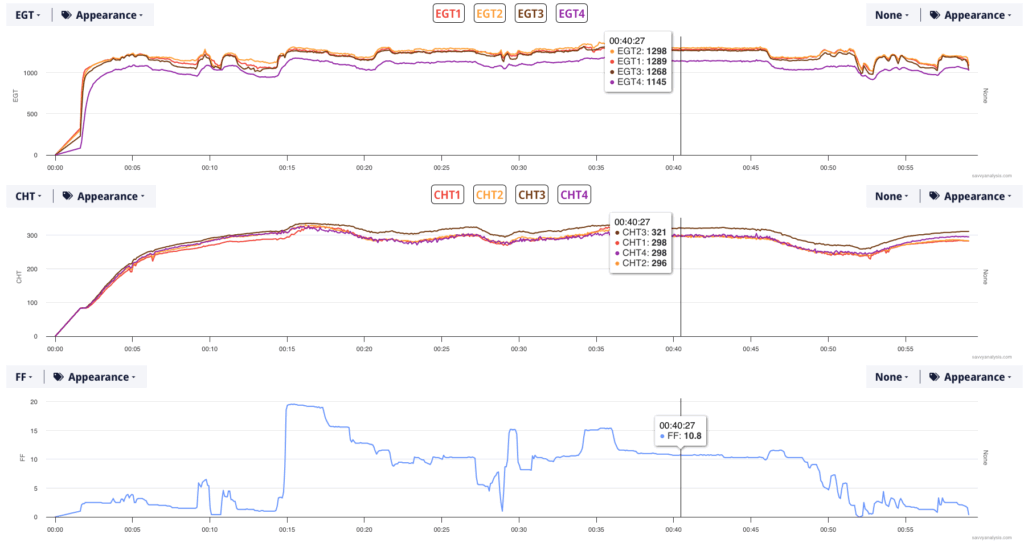

Next is a Cessna 182 powered by a Continental O-470 and data from an insight G3 with a 1 second sample rate. Here’s a typical flight.

EGT 5 is low at idle, normal at takeoff then high when the mixture is leaned for cruise, then low again at idle. High EGT is often caused by weak spark, but that doesn’t explain why it’s low during idle and normal during takeoff and initial climb. Also, EGT 6 is having problems throughout. On big bore Continentals cylinders five and six are connected with a crossover tube at the front of the engine. That tube is a notorious source for induction leaks so we took a look at MAP.

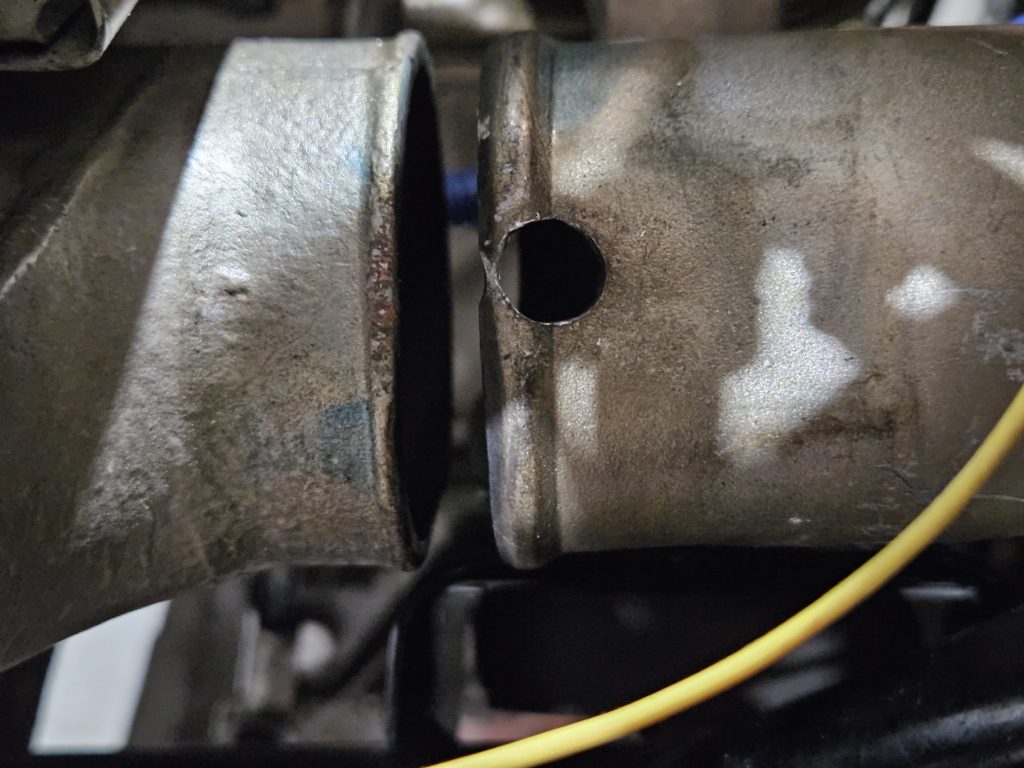

Idle MAP is 17.4″ vs the 12-14″ we should see at sea level. We recommended checking induction for leaks and here’s what they found.

That hole can be used as an alternate air source, but this one had a hole in the sleeve that was covered with a clamp.

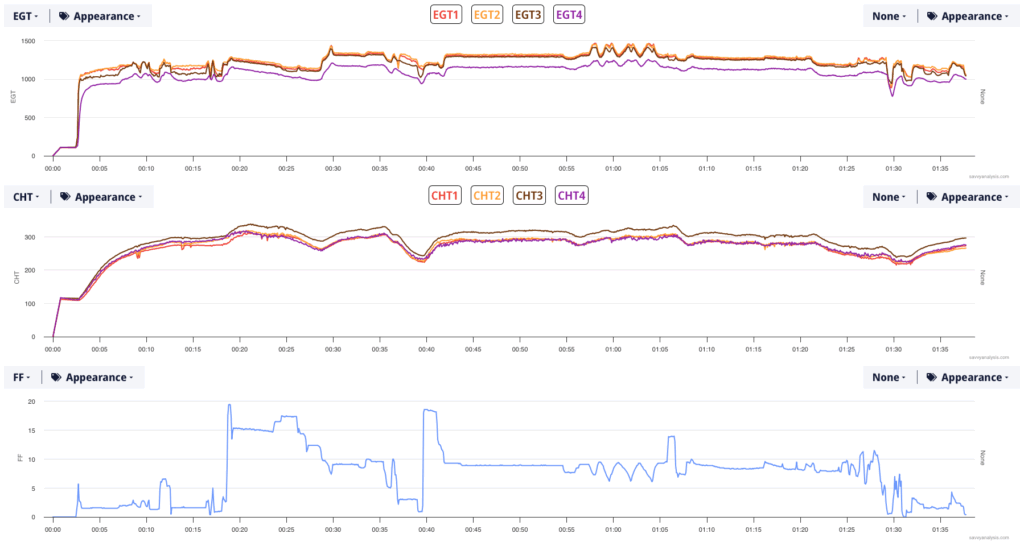

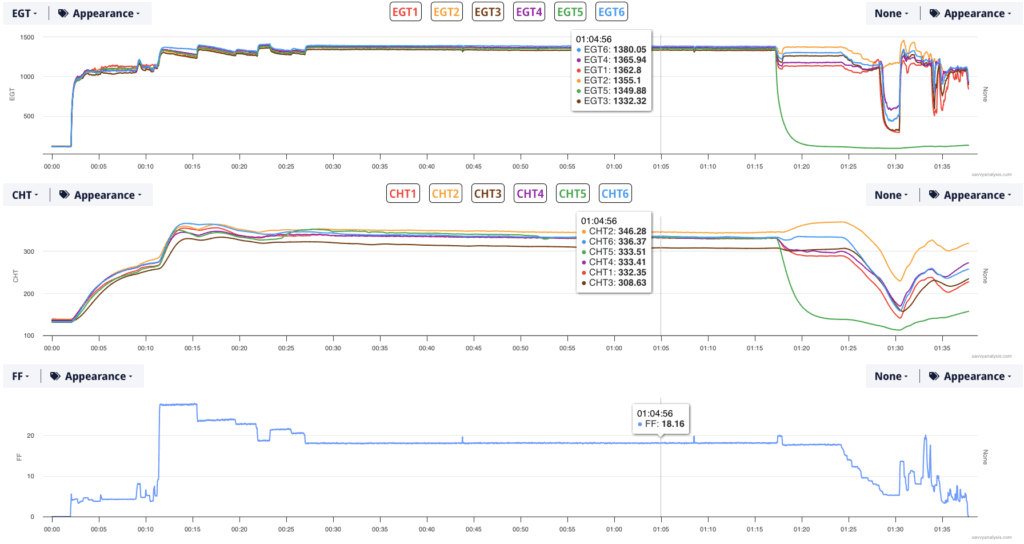

We’ll finish this month with data from a Cirrus SR22 powered by a Continental IO-550 and data from a Garmin Perspective with a 1 second sample rate.

That had to be a shock. Takeoff was at 11 minutes. An hour and 6 minutes later cylinder 5 had a catastrophic failure. Here’s what I wrote on the ticket —

First of all congratulations for getting back on the ground safely. That’s not a small thing.

I hate going out on a limb, but after reviewing the data for recent flights I think I can confidently say that this wasn’t caused by poor power plant management and getting that cylinder too hot. The CHT range in recent flights is great.

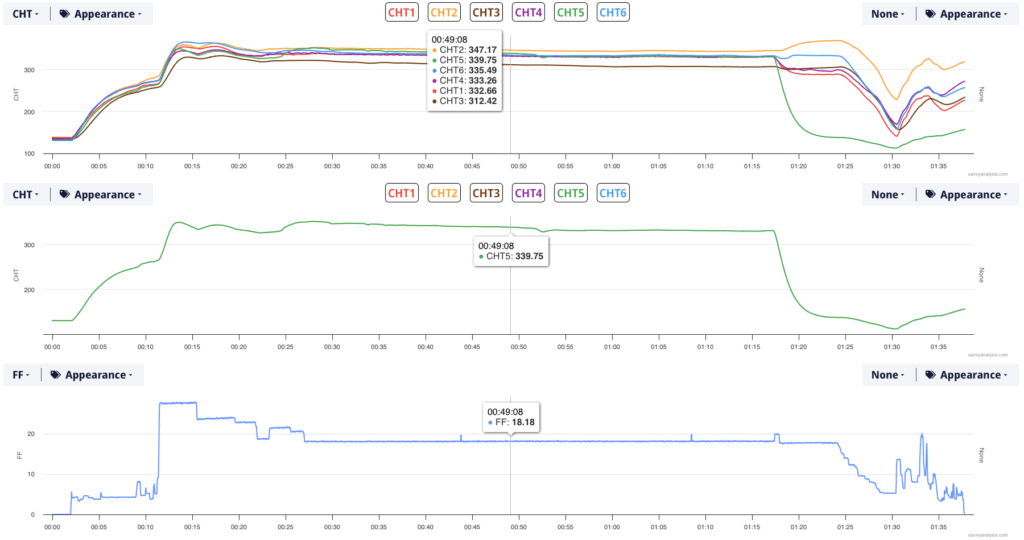

On that flight, there’s a little bit of a fluctuation in CHT 5 where the other cylinders don’t move. I set up a graph to show all CHT’s below, and CHT5 isolated below that just so you can see the context of the moves.

I know if this were me, I would be asking two questions. Could I have seen it coming and did I do anything to cause it. It’s probably not much comfort that the data isn’t full of answers. On the other hand, it does kind of shine a light on other possible causes, like metal fatigue, or torquing…