Each month, my colleagues and I tag some of our tickets as puzzler candidates. You never know at the beginning of the month what you’ll wind up with as the deadline approaches. The worst case scenario would be a collection of similar anomalies – like clogged injectors – all from the same make and model of airplane. A more interesting scenario would be lots of different anomalies found on different makes and models representing the broad spectrum of GA. We don’t have a twin this time, but the luck of the draw gave me a collection of engine problems from a Cirrus SR 22T, a Glastar, a Piper Lance and a Cessna T182T.

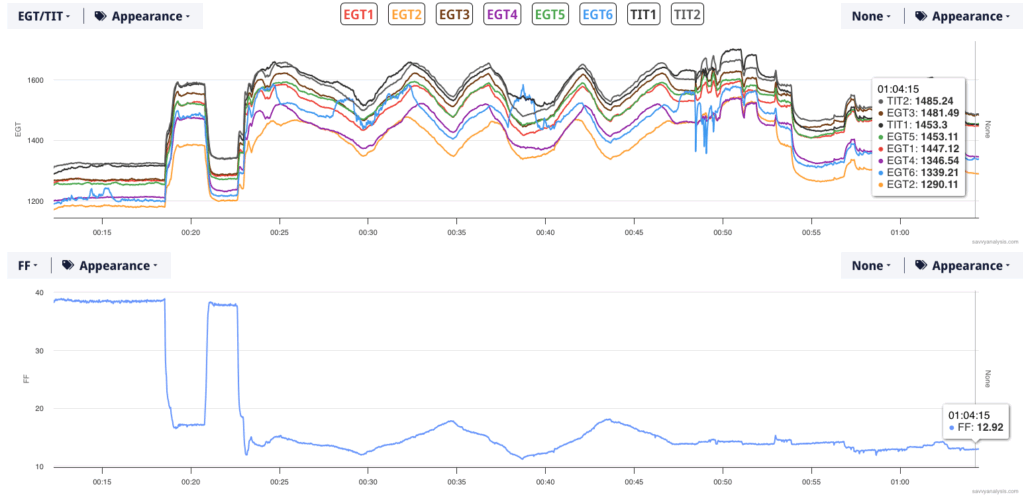

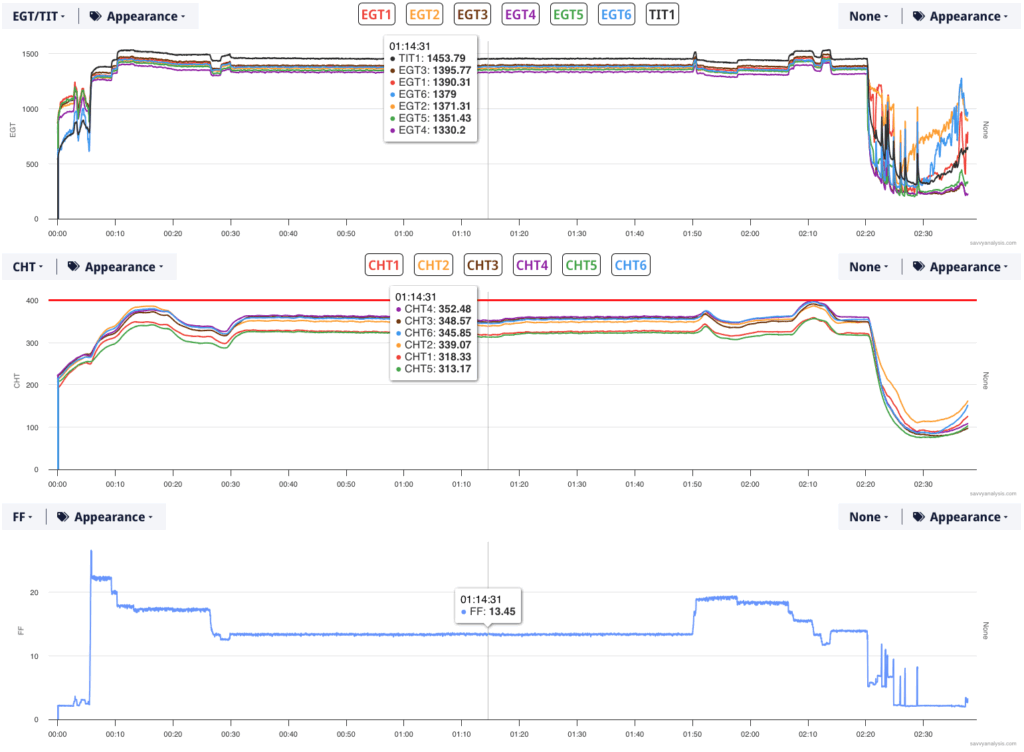

Let’s start with a Cirrus SR 22T powered by a Continental TSIO-550 and data from a Garmin Perspective with a 1 second sample rate. Here’s a set of mixture sweeps with EGTs on top, with CHTs and FF below.

Let’s isolate EGTs and FF in flight.

The owner reported “cannot run LOP.” We have wobbles in the EGT 6 trace even at max FF at the 15 min mark, then again whenever FF gets to the low spot around 12 GPH. Must be a clogged injector, right? If it is, why isn’t EGT 6 high at Max FF? Why are these wobbles in the trace intermittent? GAMI spread showed —

00:41:26-00:42:47

EGT4 peaked at 14.37

EGT3 peaked at 14.26

EGT5 peaked at 14.01

EGT6 peaked at 14.01

EGT1 peaked at 13.94

EGT2 peaked at 13.53

GAMI spread is 0.8

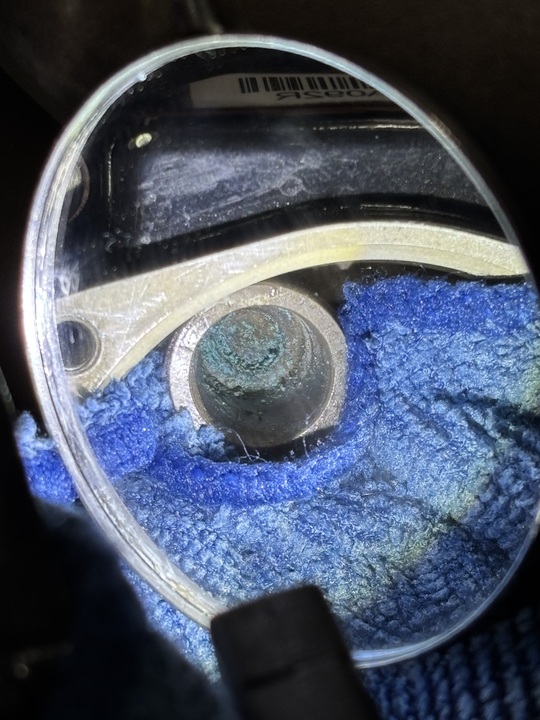

The owner reported “The roughness is about every 0.1-.3 seconds where it feels like a jolt. Not constant.” A mag check showed the problem was cyl 6 on the L mag. So plugs were cleaned – no change. The ignition harness passed its test. But we’ve seen cases where the ignition lead will pass a static test on the ground and still have intermittent issues in the air. When the shop opened up the L mag here’s what they found.

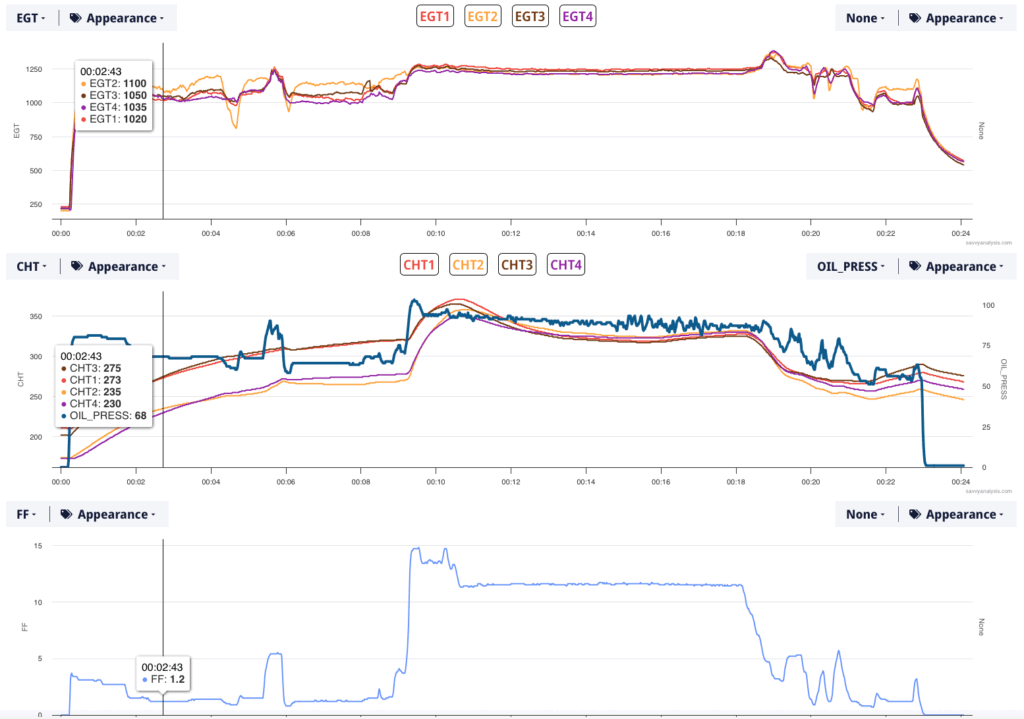

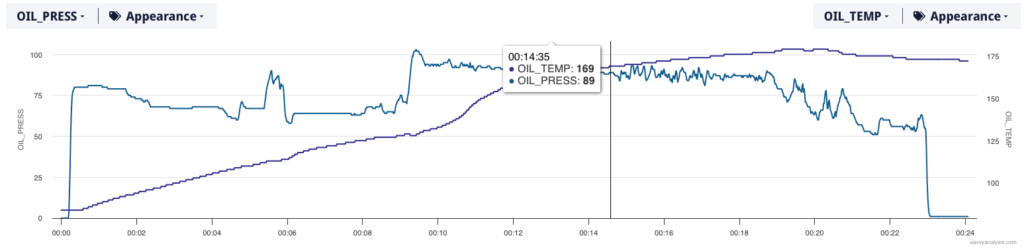

Next is a Glasair Glastar powered by a Lycoming IO-320 and data from a Garmin G3X touch with a 1 second sample rate. The issue is oil pressure so here are EGTs on top, with CHTs and oil pressure in bold below, and FF below that.

The owner reported —

This is a post oil change flight. I did a ground run first and found no leaks. Then about half way through the flight I noticed that the oil pressure was fluctuating between as much as 85 and 94 psi. This is not normal for my engine, oil pressure is normally much more steady. I did change to the Challenger CP48110 cleanable filter during this oil change, previously I used a Tempest filter. Post flight I pulled the cowling again and everything looks to be in order. Any ideas as to what might be causing this fluctuation? The only thing that is different is the new filter. I use Phillips XC 20W50. Air bubbles in the lines perhaps?

I understand the stainless steel mesh filter has a higher flow rate than the paper filters, could that be the cause?

Why does the fluctuation start at the 15 min mark? Let’s look at oil pressure and oil temp.

Aha! Fluctuations begin When oil temp reaches 170º. And we have a “what’s the last thing you changed” variable to consider. The owner pretty much had it solved with his first post, then he added —

We discovered the problem! The engine builder had set the oil pressure to high for this new high flow filter. Since there is less pressure drop over the filter now the pressure to the regulator was too much for its current setting at it seems the over pressure pop valve was opening. Apparently the theory is that the pressure would rise reach the pop valve and then bleed back down until it closed, the pressure would rise again, and repeat. I lowered the regulator setting by one full turn (about 5 psi) and everything is looking good now. Since the adjustment corrected the condition I think we have found the problem. Looks like it’s just a lower resistance filter combined with a high preset oil pressure that manifested into this fluctuation. Thank you for your help.

Next is a Piper Lance powered by a Lycoming IO-540 and data from a JPI 830 with a 1 second sample rate. This is a typical flight before the reported anomaly. Here are EGTs, CHTs and FF.

EGTs 6 and 1 are high throughout. Might be weak spark or an induction leak. Could be one of each since 6 and 1 are on opposite sides and opposite ends of the case. Even with these outliers the engine could operate LOP in cruise. The next flight showed —

And the owner reported —

After leveling off from climb i set manifold to 22″ , rpm to 2400 and leaned. Shortly after the engine ran rough and began shaking the plane pretty good. It lasted about 3 mins and than stopped. The plane ran fine but than on descent it started to shake again but didn’t last to long.

EGT 2 is low, but seems benign compared to the report of the plane shaking. The owner reported —

The plane finally got in the shop. We found a bent push rod from a stuck valve on #2 and a bad spark plug was arcing down in the electrode not on the tip.

Weak spark and a bent pushrod. We’re a little surprised not to see the stuck valve event in the data. That would typically be a dramatic drop in EGT and CHT as combustion is interrupted. Maybe the weak spark masked the stick valve event.

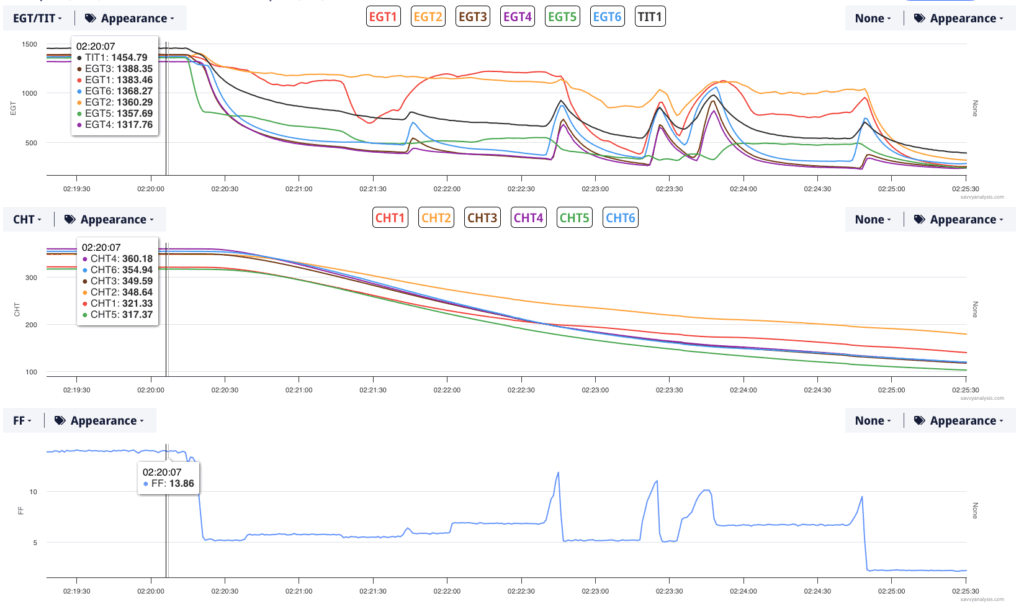

We’ll finish this month with a Cessna T182T powered by a Lycoming TIO-540 and data from a Garmin G1000 with a one second sample rate. This flight ended with a forced landing when a cylinder failed at the 2 hr 20 min mark.

With a failure like this, it’s natural to wonder if the pilot did something to cause it, and is there something in the data that would’ve alerted the pilot to the impending failure? In this case we’re not seeing either. Let’s zoom into the moment of failure.

EGT 5 drops first. The pilot felt roughness and immediately reduced power. Kudos for grace under pressure, as the pilot found a nearby airport and got the wounded bird onto the ground in less than 5 minutes. Since cylinder 5 failed first, that was the first valve cover to come off and the problem was spotted. The valve spring on the cyl 5 intake valve failed.