Why a thorough, independent prebuy examination is so essential, even for a simple 172.

The prospective buyer was looking for a Lycoming-powered Cessna 172 Skyhawk, and had a budget of $35,000. He searched online and found one being offered with an asking price in the high 20s, a price that left some room in his budget to fix and upgrade a few things.

A Google search revealed that the subject aircraft had served in the Texas Civil Air Patrol, and then somehow made its way to another owner in the Midwest, several hundred miles from the prospective buyer’s home base. Recognizing that he needed help in arranging for an impartial prebuy in a distant location, the prospective buyer decided to use my company to manage a prebuy on his behalf.

My company works with hundreds of service centers all across the nation. We consulted our database, quickly recommended a trustworthy shop near the seller’s location, and set up the prebuy examination on the shop’s schedule. As is our practice with all managed prebuys, we provided the prebuy shop with a two-phase checklist customized to the aircraft being examined.

Two-phase approach

Our two-phase approach to prebuy examinations is deliberate. Phase One of our prebuy checklists focuses mainly on the engine, propeller, and other items forward of the firewall. We do things this way because firewall-forward is where high-cost discrepancies are found most often and can be detected quickly with little disassembly of the aircraft required.

If we find any show stoppers during this phase, it gives our client (the prospective buyer) an opportunity to walk away from the deal with minimum expenditure. On the other hand, if the aircraft looks clean during Phase One, then our client can opt to proceed to Phase Two which concentrates on airframe items, including landing gear, empennage, interior and instrument panel items.

While awaiting the appointment for the prebuy examination, we performed a preliminary review of the aircraft logbooks, and arranged for the aircraft to be test flown by a local CFI (who charged only $50 for this service). The logbooks seemed to show a decent maintenance history, with no extended periods of disuse. The CFI came back with a favorable report: The airplane’s systems appeared to be in working order and the airplane seemed to fly straight and perform well.

So far, so good.

Physical exam findings

Once the aircraft arrived at the shop and the Phase One examination was performed, however it told quite a different story. My technical director Jeff Iskierka reported on the client’s ticket:

“What is under the hood is NOT in line with how it flies and the story told by the logbooks…”

Jeff provided the client with a series of annotated high-resolution photographs to help the client understand the issues that had been found. They documented a dozen and a half discrepancies, some of them fairly serious airworthiness items that definitely should have been caught and cured during the previous annual inspection (but obviously weren’t).

This certainly didn’t speak well of how this airplane had been maintained during the past several years during its post-CAP career. Jeff’s recommendation to the client was to…

“…walk away from this one. … This would be a significant project, and has potential to become a real money pit.”

One of the advantages of using a professionally managed prebuy service is having access to a team of seasoned maintenance experts. Having some additional sets of experienced eyes is often extremely helpful in gaining perspective.

My colleague Paul New—a world-class expert on Cessna maintenance who was honored by the FAA in 2007 as National Aviation Maintenance Technician of the Year—offered this thought after reviewing the photographic evidence:

“This looks to me more like a restoration project. The items in the photographs are all fairly obvious indications of flagrant maintenance neglect. I can only imagine what might be found in the hard-to-see places…”

As usual, our checklist clearly instructed the shop to stop work after reporting the results of Phase One, and await further instructions before proceeding with the Phase Two items. The client did not waste much time in reaching his decision:

“A picture truly is worth a thousand words…. it sounds like I could easily put another ten grand into this airplane and still have a Skyhawk with a high-time engine and a slew of other problems. I am not looking for a project airplane; I want something I can fly now. If everyone agrees, I am going to pass on this one, and try to find another Lycoming-powered Skyhawk that doesn’t need a restoration.”

This was clearly a well-informed decision by the client, and a wise one in our judgment.

Some lessons learned

So what can be learned from this prospective buyer’s experience?

- A good prebuy is cheap insurance. Imagine the horror story that would have unfolded for the owner if no prebuy had been conducted.

- The prebuy needs to be independent. Sellers commonly offer to provide an airplane with a “fresh annual.” Considering the condition of this aircraft, would it be a good idea to trust the judgment of the seller’s mechanic?

- The prebuy must include a physical examination. Remember the logbooks looked good, and the airplane reportedly flew well. But when we looked under the hood, it was a whole different story.

- It’s smart to structure the prebuy examination in phases. The prospective buyer’s costs would have been much higher if we’d commissioned the entire prebuy at once or, worse still, asked for a full annual inspection (as so many buyers do). The staged approach allowed our client to walk away after a relatively small investment in Phase One of the prebuy checklist.

- It’s never a bad decision to walk away. My firm has managed hundreds of prebuys, and we often see clients become so emotionally invested in an aircraft that they just can’t imagine not buying it. Sometimes, even when faced with overwhelming evidence that they’ve fallen in love with a lemon, they still go ahead with the purchase (against our advice). In this case, the client had the good sense to “know when to fold ‘em.” It won’t be long before a better airplane comes along.

How common are post-prebuy walkaways?

It depends. We’ve managed prebuys on all sorts of aircraft from 50-year-old Piper PA-28s to three-year-old Pilatus PC-12s, and just about everything you can imagine in between. As a general rule, we find that prebuys on older, lower-priced aircraft tend to focus mainly on making a buy/no-buy decision, whereas prebuys on newer, higher-priced aircraft tend to focus mainly on price.

The physical examination of older aircraft is far more likely to uncover serious issues like structural corrosion or improperly repaired damage that are uneconomical to repair and therefore outright deal-killers. The examination of newer aircraft often reveals airworthiness discrepancies, but usually they are dealt with by renegotiating the selling price prior to closing the sale.

We try hard to eliminate the cats and dogs through diligent logbook review so that we’re as sure as we can be that the aircraft is a viable purchase candidate before committing to a physical examination. But from time to time the logbooks don’t tell the whole story, and the physical examination exposes nasty surprises. That’s certainly what happened with the Scuzzy Skyhawk.

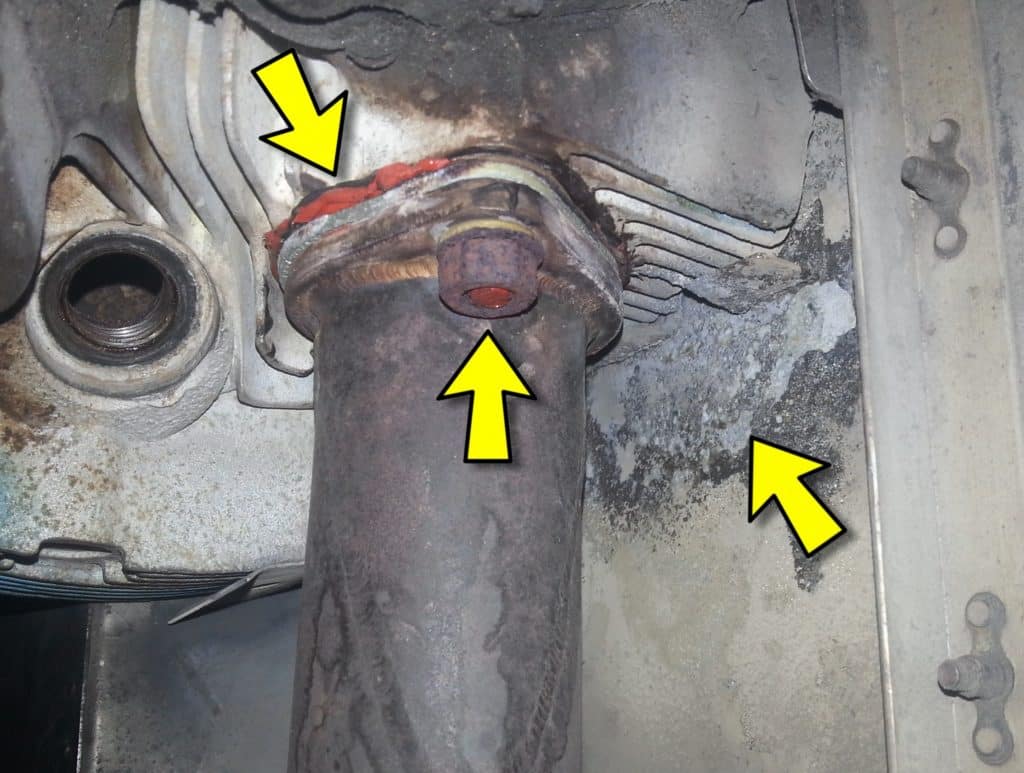

Shame on the A&P who let this pass. Exhaust gasket leaking badly. Attempted to fix using RTV (a no-no). No exhaust stud threads protruding through nut. Exhaust damage to firewall. This cylinder and exhaust riser flange are probably unrepairable at this point. A neighboring cylinder looks much the same.

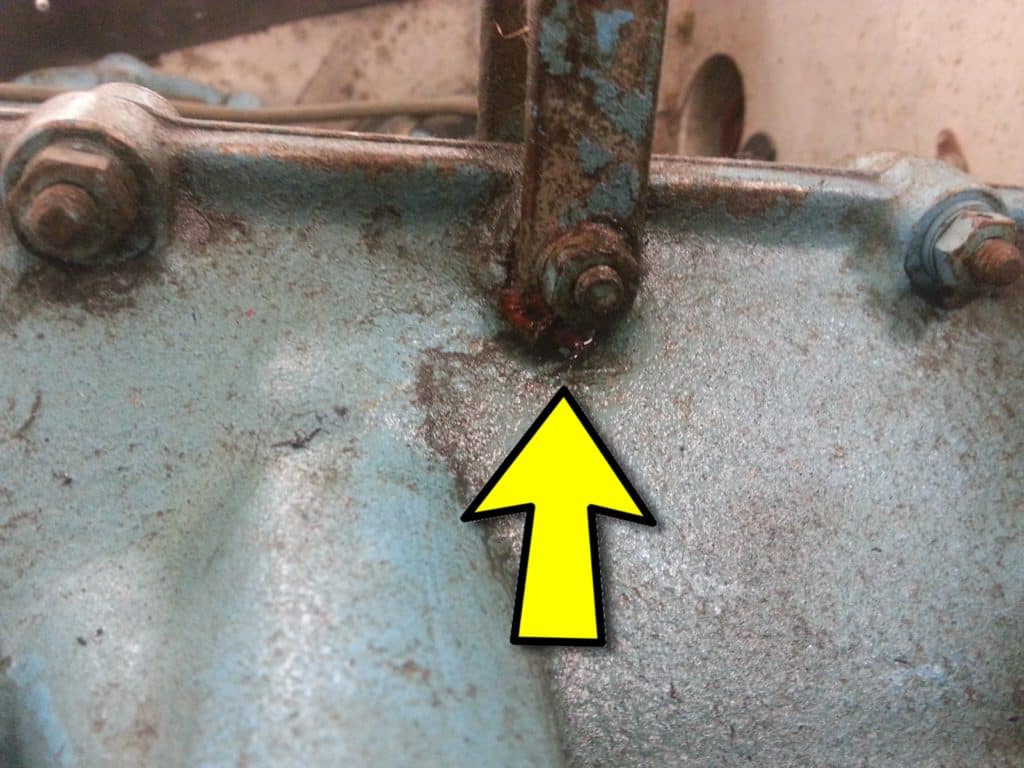

Oil leaking at crankcase top spine bolt. Attempt to stop leak with RTV unsuccessful. Leak will continue until engine is overhauled.

Firewall grommet assembly missing, allowing main battery lead to chafe on firewall. If left uncorrected, this could result in a total electrical failure and/or electrical fire.

Unauthorized patch to cracked spinner bulkhead. No repairs are permissible here because of balance and vibration issues. The bulkhead must be replaced with a new one.

What a mess! Numerous places where wires are improperly secured and chafing. Primer lines are rubbing on engine mount. Engine has no oil filter installed, only a pressure screen.

View up the tailpipe. Flame tube is broken and there’s a crack around the base of the tailpipe. The entire muffler assembly will have to be replaced or overhauled.

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: