Thanks to the virus, I think we’re all logging more flight simulator time lately. I was talking with a game-designer friend about sims and haptics. To save some of you running to the dictionary, haptics are kinesthetic cues given by electronic devices. Like when your phone buzzes if the ringer is muted. Or when the little circular device they give you at the restaurant blinks and buzzes to tell you your table’s ready. Or when the game controller begins shaking when you drive off the pavement onto a gravel road. Or when you put your simulated airplane of choice into a steep powered dive and get tail flutter before you recover – or buy the virtual farm.

Failures have been part of simulators since the beginning. Instrument failures, control surface failures, and different types of engine failure. We can fail things in the sim that would be too dangerous to fail in real life – fires, bird strikes and gear failures for instance. We were wondering how many more releases it will take before sims will realistically render more common non-catastrophic malfunctions, like a clogged injector, carb ice, a failed spark plug or a magneto failure. You can fail a mag in X-Plane but your only clue is a slight rise in EGT – at least with my admittedly ancient CH controller. In a real airplane most of these events will give you a tactile sensation – maybe just a little roughness in the yoke that’s not normally there. But that and analysis of the data should be enough to verify there’s a problem.

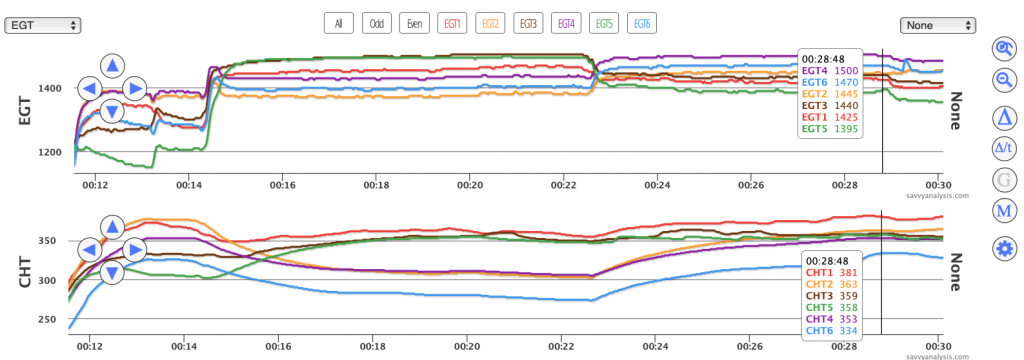

First up this month is data from a Cessna 182 with a Continental O-470 and data from a Garmin G3X with a 1 sec sample rate. Typically I like to show EGTs, CHTs and FF but in this case FF is not logged – which is why the GAMI tool is grayed out. Cursor isn’t noting anything in particular, just out of the way so you can see the patterns.

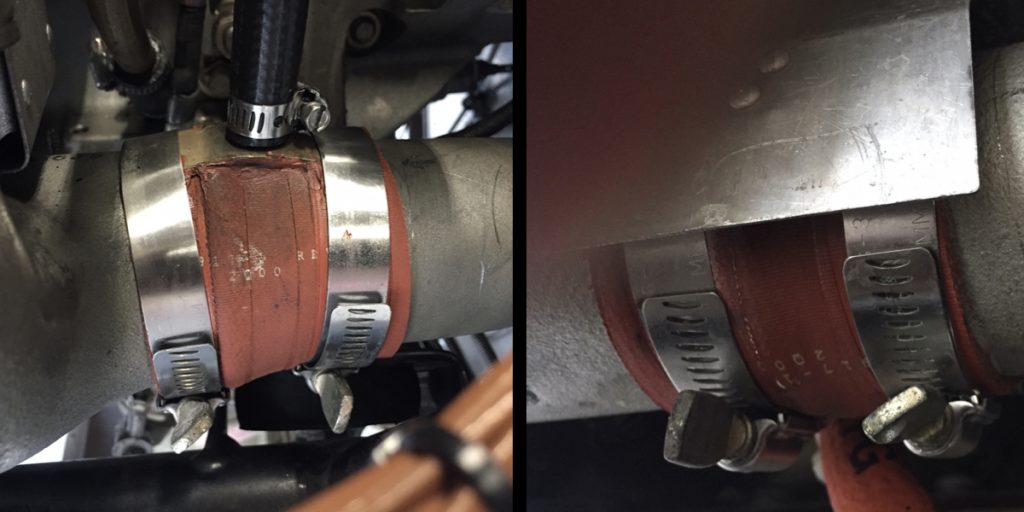

This is the takeoff and climb, and the first big change happens just after the 14 min mark when the pilot leans for cruise. The second big change happens at about 23 minutes when carb heat goes on. We know that partial carb heat disturbs the incoming air and can help identify an induction leak. In this case partial carb heat changes the mixture distribution dramatically. We recommended checking for induction leaks on the 2-4-6 side and a couple of moderate leaks were being caused by loose clamps or clamps not being quite square and one was loose because of a bracket connecting a hose to a backup vacuum system that had been replaced during a previous panel upgrade.

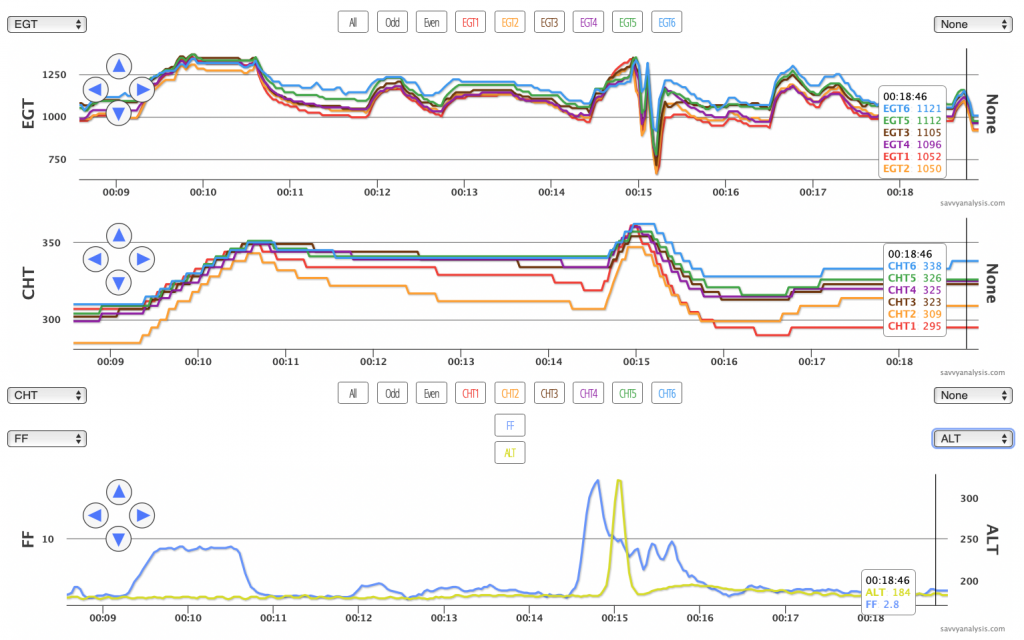

Do you always insist on the longest available runway? Remember what your CFI told you about the runway behind you? Here’s data from a Cherokee Six with a Lycoming O-540 engine and data from a JPI 830 with a 2 sec sample rate. EGT on top, then CHT, and FF and ALT – the yellow trace – below that. I chopped off the first nine minutes of taxi-out so the chart includes a runup, some idle time. an aborted takeoff and taxi-back. Nothing important about where the cursor is end just out of the way so you can see the patterns.

The airplane gets about 140 feet into the air before power is cut and he lands again. This field happens to have two parallel runways, with one being about half the length of the other. Fortunately the pilot insisted on the long one. Maybe that’s because this was the first flight after an annual inspection and the pilot had read Mike Busch’s articles about flights after maintenance. Here’s one from November, 2018.

It’s not really fair to make this a Puzzler and ask you to guess the cause, but if you guessed fuel you’re right. When the plane went back to the shop, they found one of the five nuts to the fuel sector/sump drain was loose and fuel was staining and dripping around the fuel selector. Further investigation revealed that when the fuel filter was reinstalled after cleaning, the retaining clip didn’t seat properly and the pump stopped pumping. And one of the lines that had been loosened to allow for cleaning the filter hadn’t been tightened.

Why wouldn’t you notice this during runup? It was probably leaking but with the reduced amount of fuel for taxi-out and runup it was less of a factor than when FF gets to 18 GPH.

I’m in the middle of my annual right now and this one got me thinking about how far my fuel sump is from my exhaust pipe and maybe I’d better check the retaining pin on that fuel filter one more time.

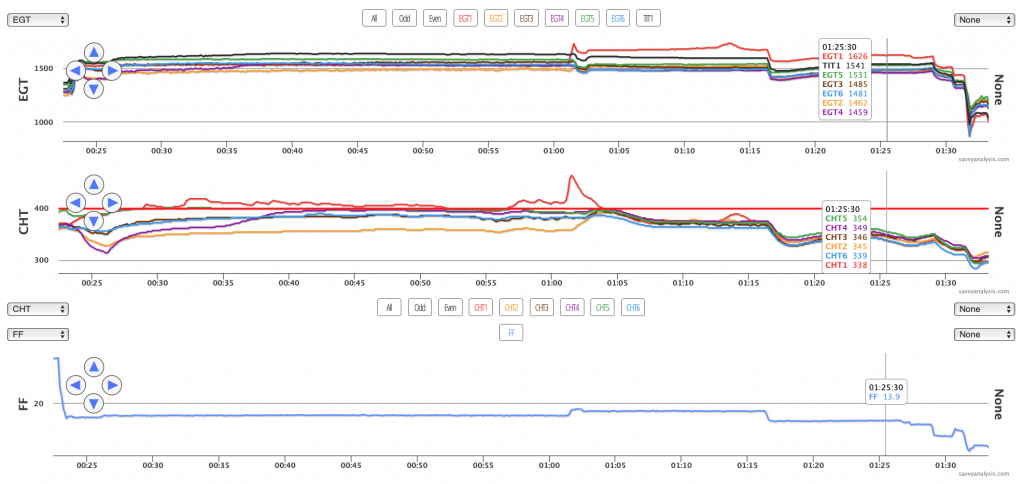

We’ll wrap up this month with data from a Beech Bonanza 36TC with a Continental TSIO-520 and data from a JPI 800 with a 2 sec sample rate. Taxi out, runup, takeoff and climb were all normal so I chopped them off to concentrate on the event at the 1 hr mark. Data starts with the big mixture pull at 23 mins and goes until shutdown. Standard layout of EGTs, CHTs and FF.

What is the event at the 1 hr mark? Let’s start at the left side of the chart. The red trace of CHT 1 began rising as soon as leaning began, and CHT 1 is high and uneven until the event. Meanwhile EGT 1 looks normal and doesn’t climb. EGT and CHT 4 climb together but neither is in a danger zone. CHT 2 was already lowest and remains there. What could cause CHT 1 to move around while EGT 1 and FF are stable? Friction from a broken piston ring or a cooling problem are two possibilities. But neither of those explains the spikes 35 mins into cruise.

If you’re wondering, valves were borescoped during the recent annual and none showed signs of burned spots. Back to the data, none of the EGT traces shows the oscillating pattern that burned valves often make in service.

We don’t have tons of detonation events to examine, but of the ones we have most are characterized by runaway CHT, along with a peak in EGT followed by a big drop in EGT. That doesn’t happen here. The CHT rise is quick, and once EGT peaks it stays high. When the pilot landed he opened an Mx ticket, uploaded the data and set up a shop visit with his account manager. When they pulled the plugs for cyl 1 they found this.

Where did all that FOD come from? It came from this valve.

When I first saw this I wondered if the missing slice of valve was just loose – but sill attached – for the last 30 mins of the flight and then became detached during landing. I can understand the EGT going up but I struggle with how that cylinder was able to maintain CHT with part of the valve missing. Wouldn’t compression drop so low that the cyl would pretty much be out of service? I can understand the thermal mass of the cyl retaining heat for a while – but 30 minutes? Then again, cyl 1 is in the back on this engine so incoming air blows heat from 5 and 3 in the direction of 1.

Feel free to post your comment about whether the valve piece separated in the air or as the airplane landed.