Years ago my wife got a set of books as a gift. It’s the series devoted to sweating the small stuff in life. I guess the gifter thought she needed help prioritizing. They’re on the bookshelf in her office still shrink wrapped – so much for sweating. I’m not going to read them either, because writing a Puzzler is usually a deep dive into small stuff. Sometimes a small adjustment in cooling baffles can fix an engine that’s running too hot. What’s smaller than the orfice in an injector? But often cleaning one can solve a mixture distribution problem. A small fracture in a spark plug insulator can be the trigger for a detonation event. Airplane maintenance tolerances are often measured in thousandths. We’re all about the small stuff.

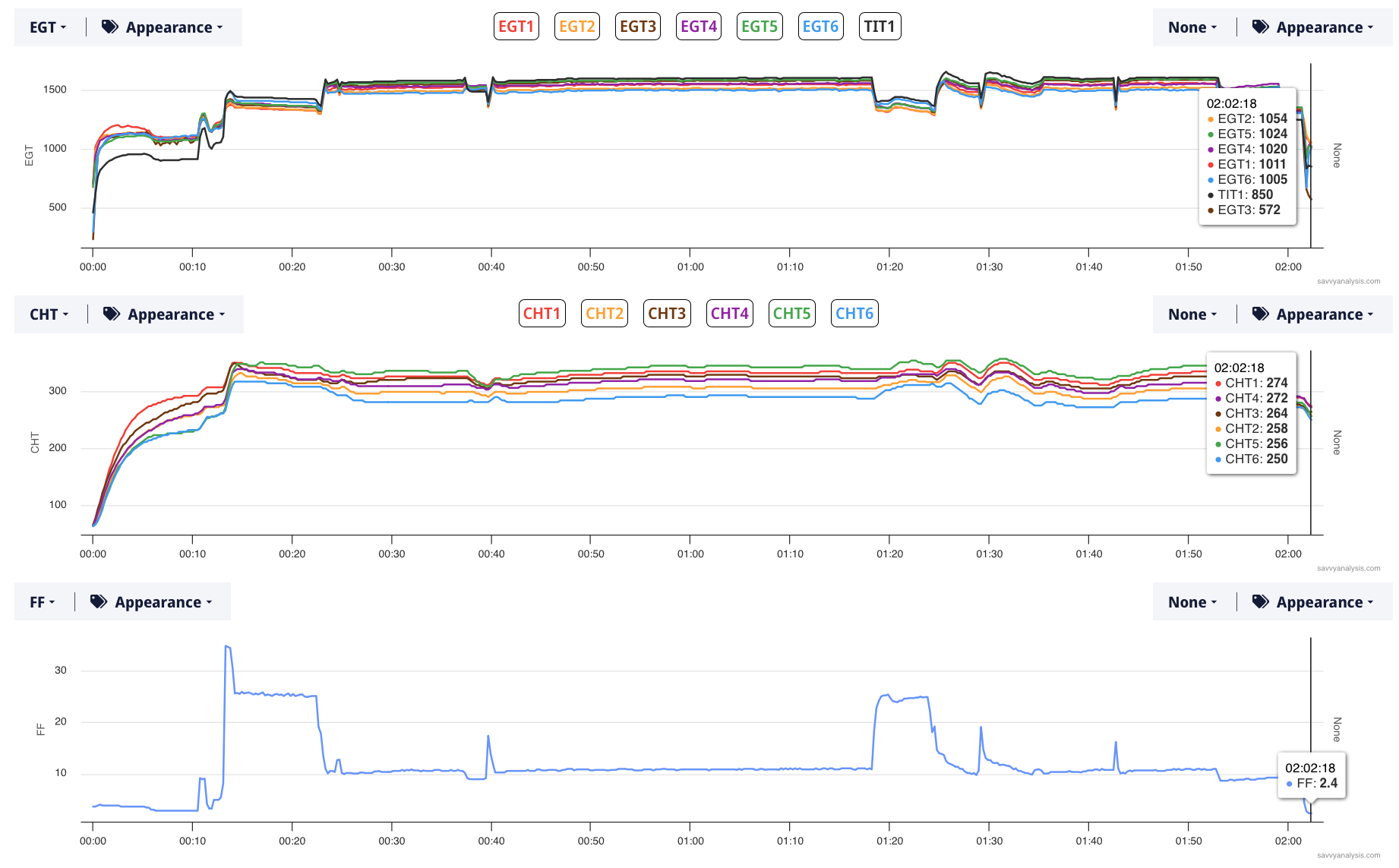

Let’s start this month with a Cessna Turbo 210 powered by a Continental TSIO–520 engine and data from a JPI 830 with a 2 sec sample rate. Layout is the default of EGTs, CHTs and FF.

This is a Savvy QA client. The analysis team supports Savvy Analysis Pro, Savvy Mx, Savvy Prebuy and Savvy QA. The issue was that the pilot couldn’t shut down the engine with the mixture control. Even at full travel, the engine would keep running. You can see an example of that here where the last data point logged shows FF at 2.4 GPH. The pilot had workarounds like turning off the mags and turning the master fuel selector to off, but that’s not how it’s supposed to work.

This became a kind of all hands on deck ticket, with advice from Savvy’s most experienced Cessna mechanics, including Mike Busch who flies behind two TSIO-520s. The analysis team looked at the data for clues, but didn’t see anything that hadn’t already been reported. That’s not necessarily bad news. Sometimes there’s value in being able to report that except for the reported anomaly things look normal. The Savvy team discussed every nook and cranny of the fuel system – the flow divider aka spider, the venting of the spider, the check valves in the fuel return lines, possible blockage in the upper deck lines (because it’s a turbo), the plumbing around the fuel boost pump, the main fuel selector, metered and unmetered fuel pressure at idle, rigging of the mixture cable (was it hitting the stop on the other side of the firewall?). Here’s a wrinkle. In the course of the discussion, someone mentioned that this problem began around the time that a set of GAMIjectors were installed.

That turns out to have been an interesting coincidence. The fuel spider had been one of the first things the shop looked at, but they decided to take a fresh look. And this time they discovered a blockage in the vent that had not been seen before. Once the vent was clean, the engine idles perfectly, and would shut down with the mixture control just like it says in the POH.

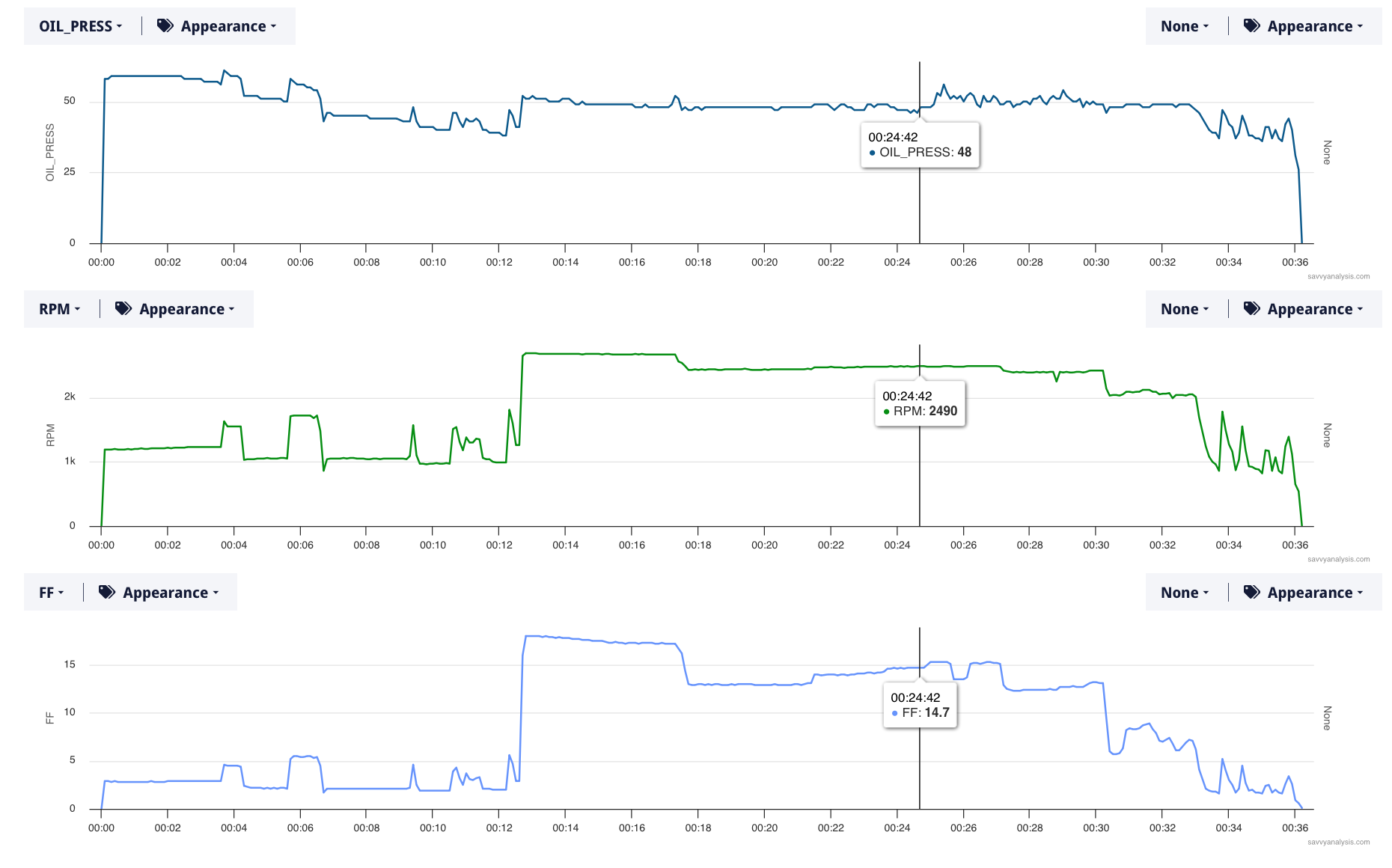

Next up is a Cirrus SR 20 powered by a continental IO-360 engine with data from an Avidyne with a 6 sec sample rate. Our client reported a surging noise from the engine, and that he hadn’t seen anything unusual in the engine data in real time. This screenshot is oil pressure, RPM, and FF.

It’s tempting to write off the oil pressure jumpiness to the right of the cursor as bad data – maybe a failing sensor or a loose connection. Except for the reported surging. A bad connection wouldn’t cause surging. We were surprised not to see movement in the RPM trace when oil pressure starts acting up. Normally, that’s where we’ll see evidence of surging. Did you ever forget to cycle the prop during your run up and you got an RPM surge when you applied full power for takeoff? Don’t ask me how I know this.

This was a QA client, too, and our recommendation was to “Remove the oil pressure regulator, check the sealing surface and plunger for signs of complete contact and evidence of carbon debris.” When the shop checked, they found the male connector to the transducer was missing its ‘o-rings’ so it was loose. And the other connectors in that area were contaminated with oil. The connectors were cleaned up and the plug wrapped in heatshrink (in the absence of a replacement plug) to give a better fit with the female transducer. An engine run demonstrated much steadier indications and subsequent flights have been normal.

Next is a Piper Archer 180 powered by a Lycoming O-360 engine and data from an EI CGR-30P with a 1 sec sample rate. EGTs, CHTs and FF. Nothing special about cursor placement – just getting it out of the way.

Our client reported that EGT 4 had been running low on recent flights. Our client submitted a different flight which showed EGT’s for dropping as it does here, but then staying low throughout the flight. Looking at more recent data, I found this flight with that big jump at the one hour 30 minute mark. That’s a jump of 487º. That seems fishy for a ∆ in FF of less than 0.5 GPH. Absent that jump, we would have to consider what would cause normal EGT at Max FF and then a drop of several hundred degrees in cruise. Weak spark, induction, failing valve…? But that jump led us to recommend swapping the EGT probes for cyls 2 and 4. When they pulled the probe for cyl 4, they found the tip missing and some corrosion on what was left. New probe was installed and all’s well now.

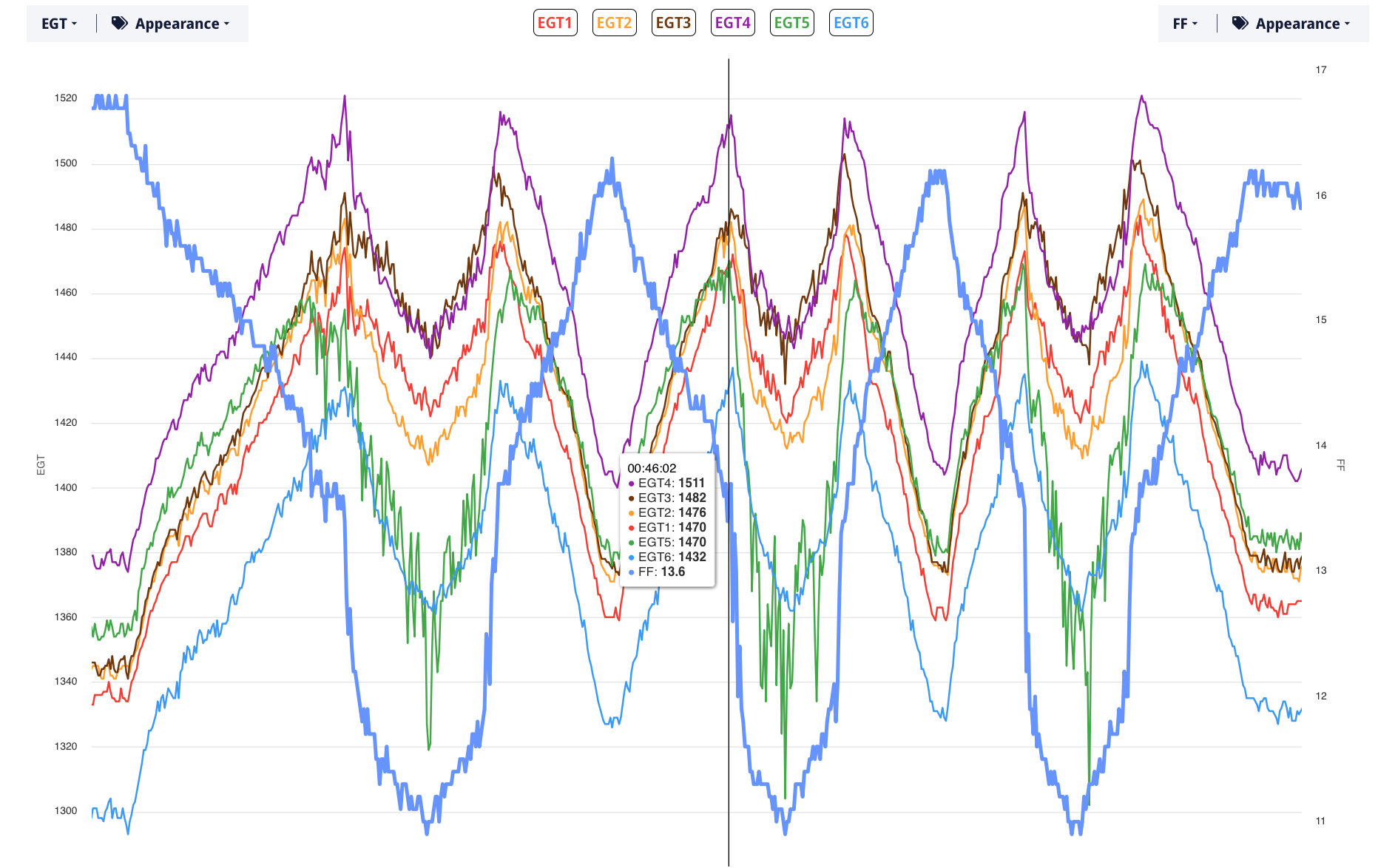

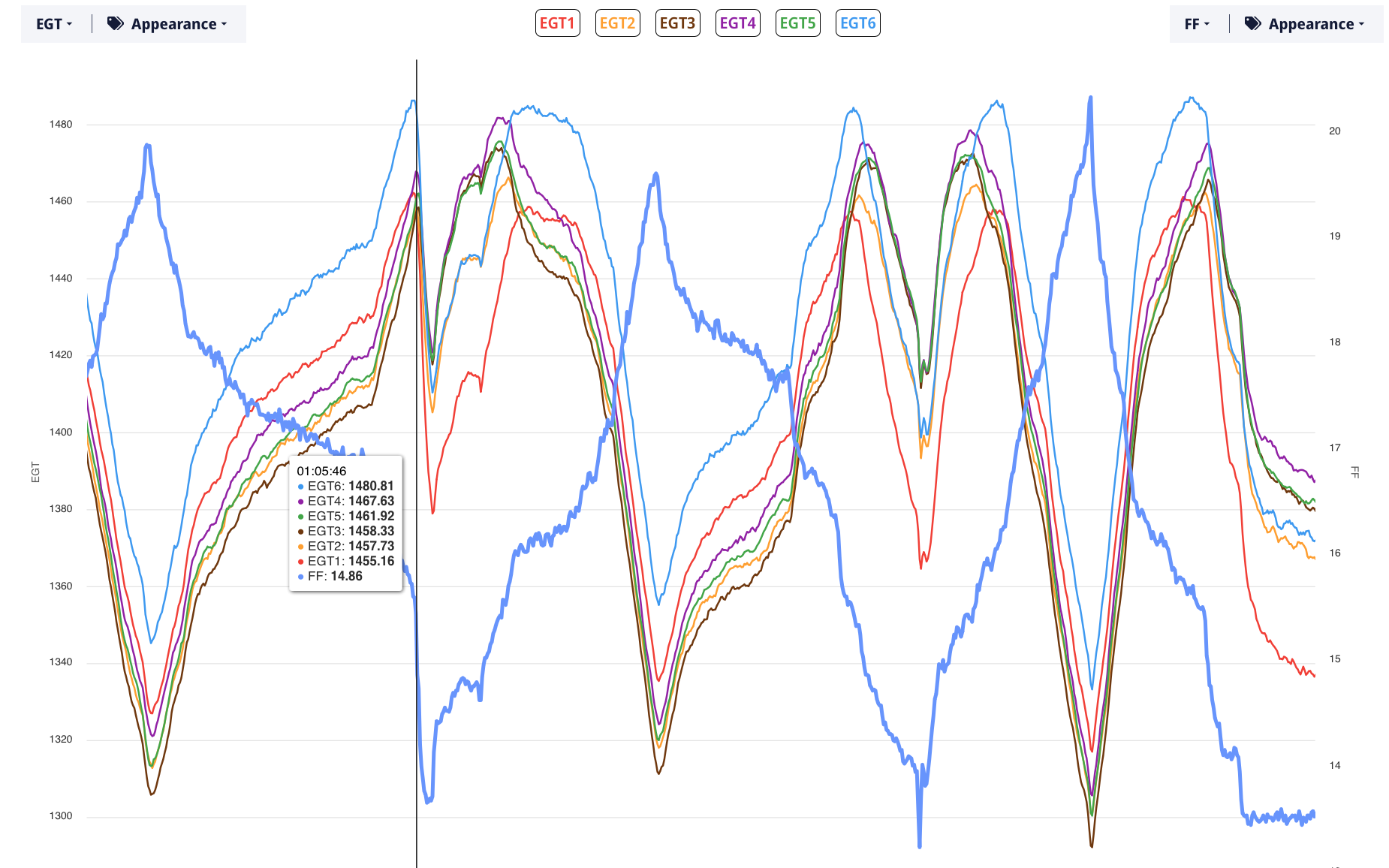

We’ll finish this month with two examples of mixture sweeps. These came in within days of one another, and I took that as an omen that I should mention it in the Puzzler. Sometimes we can use data from regular flights to address the concern, but sometimes it helps to have data from our test profile, which includes mixture sweeps and a LOP mag check. We know that gathering the data for a test profile takes time and money. That’s why we only ask for it if we think we need it. And it’s really painful to have to tell a pilot that we can’t use the test profile data they gave us and they’ll have to go back up again. So here’s one way to avoid that.

Here’s a set of sweeps from a Bonanza 36.

And here’s a set of sweeps from a Cirrus SR22.

See how the FF rate of change starts out really good and slow? Then at each cursor – right at peak EGT where it matters most – it’s too fast for us to draw reliable conclusions. Ideally we get a steady and slow rate of change from 100º ROP to the onset of roughness, and then back again, and then two more just like that. But if the FF rate of change can’t be steady all the way through, at least try and give us a steady and slow rate where it matters.