This Skyhawk’s Lycoming had a 2,000-hour TBO, but it lasted a bit longer—3,000 hours longer to be exact.

What follows is true, though the names have been changed…

It was 2011 and Unruly Flyers had a problem. This 14-member Midwest flying dlub’s only aircraft—a 1997 Cessna 172R—had a Lycoming IO-360 engine that was rapidly approaching its 2,000-hour TBO, forcing the club to decide. Overhaul would put Unruly Flyers on the ground for at least three months. Replacment with a Lycoming rebuilt might shorten the downtime but increase the cost.

Unruly’s board was struggling with this decision, and decided to coax the club’s former maintenance officer Zachary “Whit” Wittington to come out of retirement. Whit wasn’t an A&P, but he’d been flying GA for more than two decades and had proven himself to be exceptionally maintenance-savvy.

Whit agreed to reassume his former role, and at the next Unruly board meeting (pun intended) asked all the right questions:

Q: Are we having problems with the engine?

A: No.

Q: Why are we thinking about overhauling or replacing it?

A: It’s at TBO.

Q: Are we required to do anything at TBO?

A: Guess not.

Q: Why not continue it in service?

A: Uh, for how much longer?

Q: Until there’s some indication that overhaul or replacement is warranted.

A: Is that safe? How would we decide when it’s warranted?

Whit explained that several years earlier he’d attended a workshop where I made the case for doing maintenance “on-condition” rather than on the fixed timetables recommended by manufacturers. I presented the results of a five-year study of GA engine-failure accident data from the NTSB showing that the greatest risk of an engine-failure accident occurs when an engine is young, not when it’s old.

“We should worry more about engine failure during the first 200 hours after the engine is overhauled or rebuilt than during the first 200 hours past recommended TBO,” Whit explained. “Very few engine-failure accidents involve engines beyond TBO and 80% of those are due to maintenance errors rather than to any age-related cause.”

Whit recommended that Unruly enroll its Skyhawk in my company’s managed maintenance program where we help owners maintain their aircraft using this ‘on-condition’ philosophy, working directly with their shops and mechanics. The board approved. One of my most experienced account managers—Eric Svelmoe A&P/IA—was assigned to Unruly’s airplane.

The journey begins

Eric learned from Whit that the Skyhawk was averaging 300 hours per year, and had flown as much as 600 hours in prior years. Unruly had acquired the plane in 1998 with 500 hours since new, and had the Air Plains STC installed to upgrade the engine from 160 to 180 horsepower. The plane was hangared at Midwest Regional Airport and maintained by the local FBO, Midwest Air. Whit thought they did a decent job of wrenching but not troubleshooting. Some recent personnel turnover had him a bit concerned.

Whit told Eric that the club’s primary maintenance concern was that the Skyhawk’s factory rebuilt Lycoming IO-360 had over 2,000 hours. For Unruly to continue flying it a thorough condition monitoring program would need to be implemented. “Midwest Air isn’t much of a believer in borescopes,” Whit explained. “They’ve got an old clunky one that they hardly ever use, so we really don’t know what our exhaust valves or cylinder barrels look like.”

Bulletproof…almost

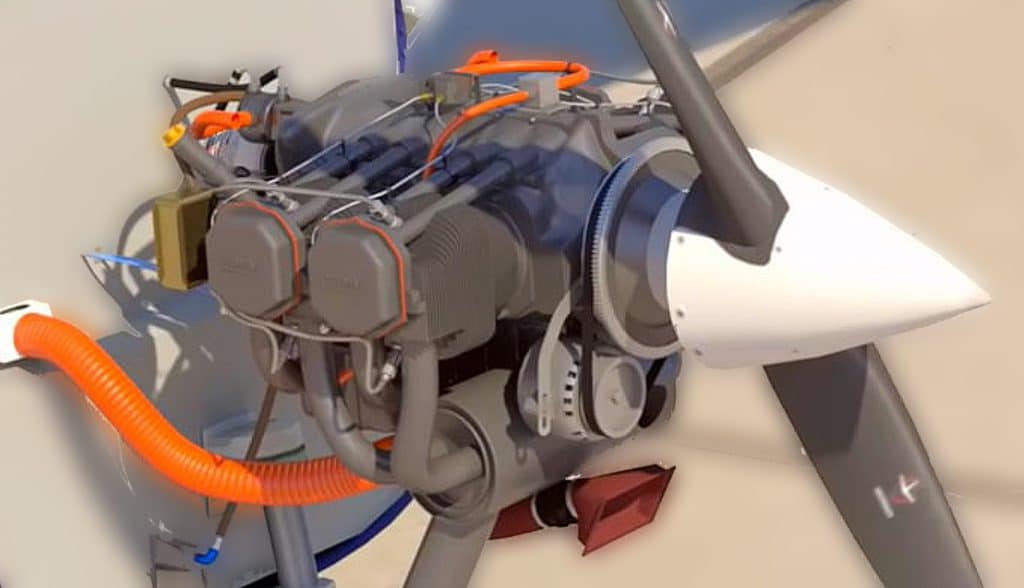

Eric—who has decades of experience overhauling and maintaining Lycoming engines—told Whit that the Lycoming IO-360 is relatively bulletproof, but does have a few vulnerabilities that need to be monitored closely. One involves the engine’s hollow-stem sodium-filled exhaust valves, which have a history of becoming eroded and pitted and vulnerable to breakage after a couple of thousand hours so would need to be inspected carefully.

Another is the cam and lifters, which have a history of spalling if corrosion occurs during periods of disuse. Eric felt that Unruly’s Skyhawk was flying so regularly that this probably wouldn’t occur. He suggest switching from Aeroshell 15W-50 to Phillips X/C 20W-50 and adding ASL CamGuard for improved protection against corrosion and wear.

A third vulnerability is sticking exhaust valves, a longstanding problem with Lycomings. Eric recommended doing the exhaust valve “wobble test” every 400 hours per Lycoming Mandatory Service Bulletin 388C. He also urged that club members be trained to recognize “morning sickness”—rough running when the engine is started cold that smooths out once the engine warms up—and to report this immediately so that the valve guide can be reamed before sticking gets serious.

Annual Inspection

The Skyhawk’s 2012 annual inspection began January 30. Engine time was now about 2,500 hours. The annual had a slightly rocky start because Midwest Air wasn’t used to us requiring detailed written cost estimates and securing Whit’s written approval for each task before authorizing the shop to proceed—but the Midwest Air’s director of maintenance got on board with this fairly quickly. Eric found their inspections were thorough, their estimates fair, and the shop rate reasonable.

Whit was present for the compression test and borescope inspection. He reported the compression test went smoothly with all cylinders in the 70s. However, the borescope inspection was a big disappointment because Midwest Air’s borescope—a Snap-On BK5500—was (in Whit’s words) “pretty much of a joke.”

The resolution and lighting were horrible, and there was no way to manipulate the camera to view the condition of the exhaust valve stems, so it was necessary to drop the exhaust system to inspect them. “I think I’d better purchase a decent borescope,” Whit said. Eric recommended the Vividia Ablescope VA-400 from Oasis Scientific for $250.

Engine Hiccuping and Popping

Fast forward 2½ years to September 2014. Engine time was about 3,250 hours. The club organized a spot-landing contest, and several members reported the engine was hiccuping and making loud popping sounds when throttled back for landing. Whit asked Eric for advice.

“Hiccuping and popping suggests one cylinder is intermittently not firing, so unburned air-fuel mixture is being pumped out the exhaust port and combusting in the manifold,” Eric explained. “Not likely an ignition problem, that would require both plugs not to fire. More likely a sticking exhaust valve, so I recommend we have the shop do a wobble test ASAP.”

The plane was due for a 50-hour oil change and Eric asked Midwest Air perform the SB 388C wobble test. All four exhaust valves passed the test with flying colors, but in the process of removing the rockers and exhaust valve springs for the test the shop discovered a rocker shaft bushing in cylinder #2 was cracked and broken. A new bushing was installed and the hiccuping and popping disappeared.

Oil Consumption Rising

Fast forward two more years to September 2016. Engine time about 3,700 hours.

“The engine used 8 quarts of oil since the oil change 35 hours ago,” Whit reported to Eric, “and I’m starting to get concerned.”

“That’s 4.4 hours per quart,” Eric said. “While that’s a bit higher than ideal, it’s not a problem beyond tolerating some oil on the belly. In high-time engines, this is often due to accumulation of sludge in the oil control rings and piston oil feed holes. We have a solvent flush procedure that can sometimes clear the sludge if it isn’t too bad. If a piston can’t be cleaned up via the solvent flush, the only cure is to remove the cylinder.”

A couple of months later, Whit reported oil consumption was 3.3 hours per quart. “It’s getting worse,” he told Eric.

“This won’t affect compression or engine power,” Eric reassured Whit. “but it’ll slowly get worse. Eventually you will start fouling plugs and spooking pilots. Then you’ll have to address it. Right now, there is no safety concern. The oil control ring solvent flush procedure may help improve things if they haven’t gotten too bad,” Eric continued. “If you’d like to try this, the sooner the better.”

“Great guidance, Eric,” replied Whit. “It is reassuring to know we’re not affecting safety of flight as long as we diligently watch oil level. I think it certainly would make sense to take a $400 gamble on the solvent flush versus spending $40,000 on an overhaul and being down for heaven knows how long. Let’s plan on doing it at the next oil change and see what happens.”

“Sounds like a good plan,” Eric agreed.

“Midwest Air has never done the flush procedure,” Whit said. “Maybe we should fly the plane to a shop that has? Doesn’t matter where, it’s only avgas.”

“I’m sure Midwest Air could do it if they follow the instructions,” Eric said. “The closest shop I know of that does this regularly is Paul New’s shop Tennessee Aircraft Services in Jackson, Tennessee, but that’s about 500 miles as the crow flies.”

“I’ve heard great things about Paul’s shop,” Whit said. “Do you think he’d be willing to squeeze us in? The sooner the better.”

Tennessee Flush

Eric checked with Paul. “We’ve done this solvent flush many times,” Paul confirmed. “We could do it next Monday if that works.”

“I’ll fly the Skyhawk to KMKL Sunday afternoon,” Whit said, “and have it at Paul’s shop first thing Monday morning.”

Eric asked Paul to do a borescope inspection while he had the top spark plugs out for the solvent flush.

“I’m looking forward to watching the solvent flush and borescope procedures,” said Whit. “Should be a great education.”

Two days later…

“We’re done with the solvent flush,” Paul reported. “The front cylinders #1 and #2 cleaned up very nicely, but the rear cylinders “#3 and #4 wouldn’t pass solvent very well even after multiple attempts. I’m pretty sure those two are responsible for most of the remaining oil consumption.”

“If oil consumption becomes intolerable, I’d suggest pulling cylinder #3 first and inspecting the cam and lifters,” Paul suggested. “If the cam and lifters look okay, then pull cylinder #4 and clean up both pistons and replace the rings. Alternatively, if the cam and lifters look bad, you may want to bite the bullet and overhaul.”

Paul provided a series of borescope images of the exhaust valves, none of which provided any reason for concern.

“Is the oil consumption any better?” Eric asked Whit after he flew home from Tennessee.

“On the four-hour flight back from Tennessee, the engine used only one quart, which is certainly acceptable,” Whit said. “Since we’re nowhere close to Lycoming’s maximum oil consumption threshold of a quarts in 2 hours, it’s not clear we need to do anything further at this time.”

1,200 hours later…

The IO-360 kept on trucking without major issues for another 4½ years and 1,200 hours. Finally, in June 2021 with the engine at 4,800 hours, Whit told Eric: “I think we’re finally between the proverbial rock and a hard place. The engine is now burning a quart every 3 hours. It’s hard to start, we’re having oil fouling problems with bottom spark plugs, and cylinder #2 compression is decreasing. I don’t think it makes sense to start replacing cylinders on a 4,800-hour engine, so it seems to me that the time has come.”

“I can’t disagree,” said Eric.

“Our Lycoming factory engine has served us very well for 23 years and 4,800 hours,” Whit said, “so we’ve decided we want to replace it with another Lycoming rebuilt.”

“I would suggest you order it directly from Air Power, Inc. in Texas rather than through Midwest Air,” said Eric. “If you order it through the shop, they’ll mark it up—that can really add up on something as expensive as a factory engine.”

“Doesn’t the shop get an FBO discount?” Whit asked.

“No, they’d pay the same price and then mark it up,” Eric explained.

“I had no idea,” said Whit.

Air Power quoted exchange prices for the Lycoming IO-360-L2A as $29,199 for a factory overhauled engine and $33,699 for a factory rebuilt. Unruly Flyers opted for the rebuilt, and placed an order with a deposit.

Initially, Air Power quoted delivery in 12 weeks, later amended to 14 weeks. As that date approached, Air Power notified Whit that due to supply chain issues at Lycoming, the delivery date for the rebuilt engine would be delayed until late December 2021, which worked out to 25 weeks. In early December, Air Power advised that Lycoming had run into additional delays and the engine wouldn’t be available until late January 2022, which slipped again to late February.

Meantime, the IO-360 was at 5,000 hours, and was having such hard starting and bad plug fouling issues that the Unruly board of directors reluctantly agreed to ground the Skyhawk until the new engine could be installed. The newly-rebuilt engine arrived in mid-February, and the plane was back in the air on March 10th.

Examining the old engine…

Naturally, we were all dying to see what the bottom end of a Lycoming engine looks like after 5,000 hours. Whit persuaded Midwest Air to pull the #2 cylinder, piston and connecting rod so he could look inside and take a few photos before the old engine was returned for core credit.

The #2 piston predictably had its oil-control ring horribly sludged up, certainly explaining the high oil consumption. Yet the #2 cylinder barrel was in remarkably good condition, with lots of the original crosshatch hone pattern still visible.

The inside of the crankcase was astonishingly clean and free of deposits. The #2 rod journal (crankpin) was in excellent condition, while the connecting rod bearing exhibited some wear but was still in pretty good shape.

The cam lobes had minor wear but no pitting or corrosion damage, and no distress deep enough to flunk the fingernail test. Had it not been for the sludged-up oil control rings, this 5,000-hour engine could have easily gone another 1,000+ hours. (Had the engine been run on unleaded fuel, it would probably still be flying!)

If you ever wondered why these four-cylinder Lycomings have a reputation for being “bulletproof,” wonder no longer. Unruly Flyers certaom;u got their money’s worth from that engine.

Takeaways

Now, not every Lycoming is going to make it to 5,000 hours—although a surprising number of them make it to 3,000-4,000 if flown regularly and given a chance. Unruly’s Skyhawk was literally the poster child for TBO-extension: It averaged 300 hours a year, lived in an area of moderate corrosion risk, always hangared, always preheated in the wintertime, never cold-started, and meticulously maintained. It had a lot going for it.

But every engine deserves the chance to continue in service “until its time comes” the way Unruly’s IO-360 did. Wouldn’t it have been felony to euthanize this engine at its 2,000-hour TBO? That’s exactly what would have happened if Whit and Eric hadn’t teamed up to continue the engine in service until it started showing signs of being old and cantankerous. There was no way of knowing in advance whether this would happen at 3,000 or 4,000 or 5,000 hours, and no reason to guess. The engine will start talking when its time approaches, you just need to make sure you’re listening.

By extending its engine’s life from 2,000 to 5,000 hours, Unruly saved roughly $60,000 from what they would have spent had they dutifully replaced the Skyhawk’s engine each time it reached its 2,000-hour TBO. I’d call that savvy maintenance.

You bought a plane to fly it, not stress over maintenance.

At Savvy Aviation, we believe you shouldn’t have to navigate the complexities of aircraft maintenance alone. And you definitely shouldn’t be surprised when your shop’s invoice arrives.

Savvy Aviation isn’t a maintenance shop – we empower you with the knowledge and expert consultation you need to be in control of your own maintenance events – so your shop takes directives (not gives them). Whatever your maintenance needs, Savvy has a perfect plan for you: