The flip side of a cylinder running too lean is one that runs too rich. If it’s too lean the usual suspect is an injector clog for those with injectors or an induction leak for carbureted engines. When it’s too rich it’s often because of something all too common – an injector misplaced into the wrong cylinder – or something complicated that’s harder to verify and probably expensive to fix.

GAMIjectors and tuned injectors from the manufacturer are engineered for a specific pair of cylinders. Typically on a 6-cylinder engine you’ll have three sets, one for each pair as you work your way aft. So you could swap a 5 with a 6 or a 1 with a 2, but not a 5 with a 1. Most of the time those sets give a good result, but we’ve offered our analysis as GAMI or TCM works with clients, especially on new installs, to refine the injector set based on trial and error and mixture sweeps. Once the spread is in the 0.5 GPH range that’s about as good as it gets. With that background, let’s take a look at some recent flight data.

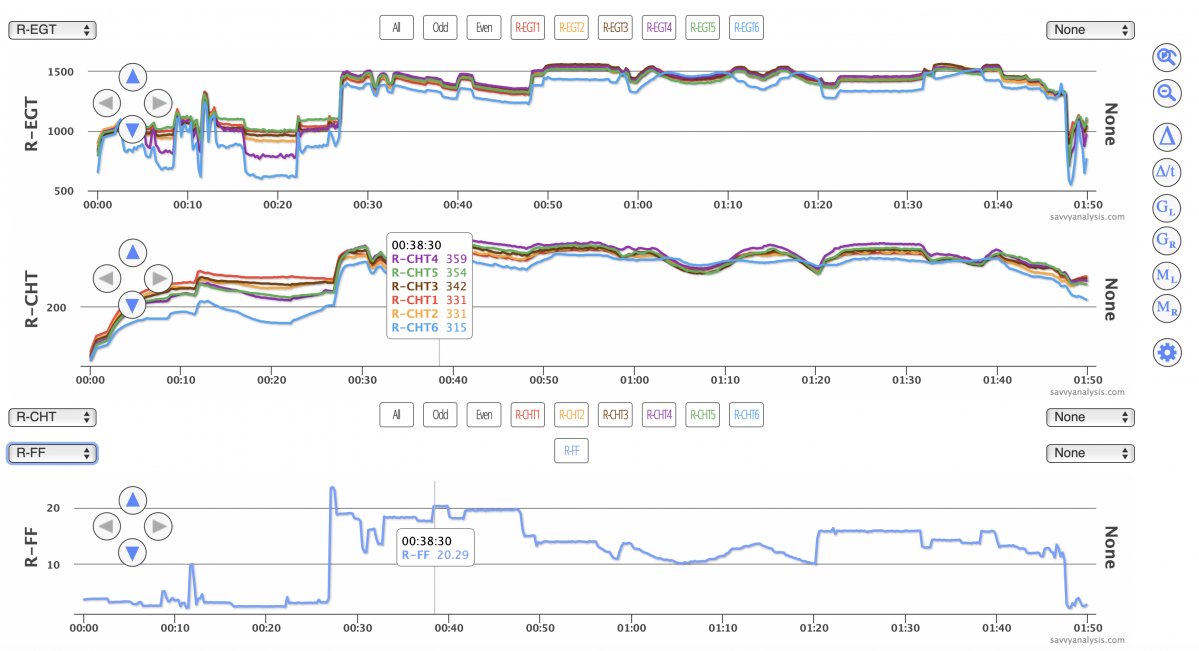

First up is data from a Beech Baron 58 with Continental IO-520 engines and data from a Garmin 500Txi with a 1 sec sample rate. This is the R engine only, with my default layout of EGT, CHT and FF.

You can see that EGT 6 – the blue trace – is low throughout, and in the mixture sweeps it peaks well after the others. CHT 6 is low too. What are the options? If we saw the mirror image of 6 in one of the other traces, we’d suspect injector misplacement. That would be a trace that is high at max FF, then peaks well ahead of the others in the sweeps. Since we’re not seeing that, what else could it be?

You can’t rule out an issue with the mag. Maybe a weak harness, a very fouled plug or a problem in the mag itself is causing poor combustion. Usually with weak spark we’ll see a higher EGT, as you do when you isolate a mag during runup or the LOP mag check of our test profile, because the slower combustion of one spark plug sends the EGT higher. But very poor combustion can send EGT and CHT lower as the cylinder struggles just to make power. There’s another possibility, and because this is a Puzzler I’ll just plant that seed for later.

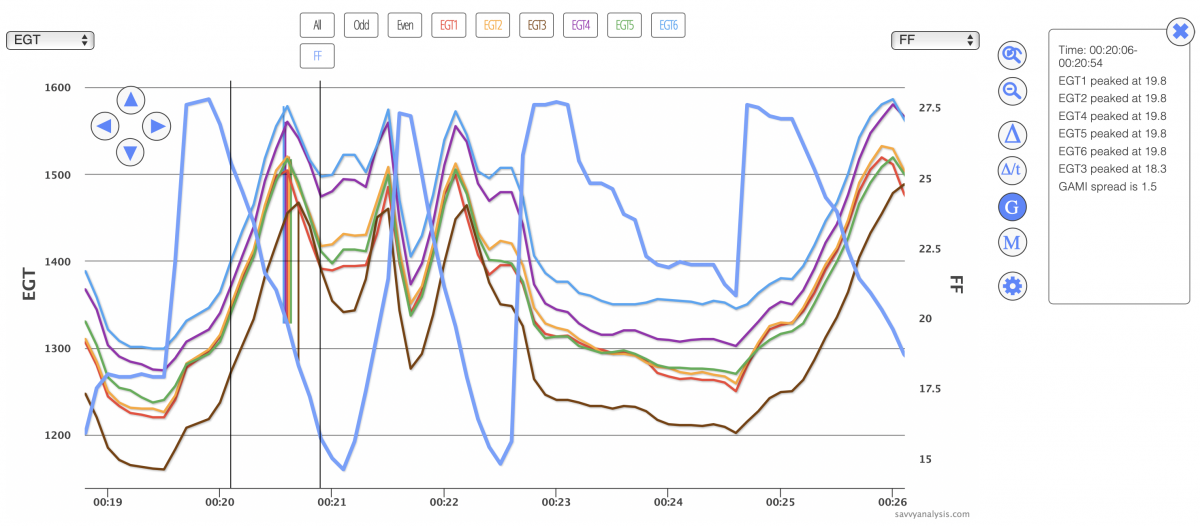

Here’s data from a Cirrus SR22 with a Continental IO-550 and data from an Avidyne with a 6 sec sample rate.

I’m using the GAMI tool to display EGTs and FF, and the two black vertical lines are clicks I made on either side of the EGT peaks to calculate the mixture spread. The numbers are in the box to the right of the graph. All cylinders peak at 19.8 GPH except cylinder 3 which peaks at 18.3 making the spread 1.5 GPH. I should note the exceptionally smooth rate of change for fuel flow, which is harder to do with the Cirrus-type fuel control than with a vernier knob. Kudos.

Now that we know 3 is running well richer than its neighbors, let’s see how that’s playing out with CHTs. Here’s the full flight with EGT, CHT and FF.

Surprised to see CHT 3 so high? We were too. You’d think with all that extra fuel it would stay nice and cool. Then we noticed that at about the 8 minute mark, CHT 3 starts to rise but takeoff power isn’t applied until about 11 minutes. Sometimes we see CHT excursions when the nose gets pushed over for cruise and the increase of incoming air moves a baffle that’s loose or mis-aligned. That didn’t happen here. Nothing much changes, the engine’s idling and CHT 3 starts rising.

There is another explanation that usually isn’t the first thing to leap to mind. But imagine that the EGT 3 probe is loose on the exhaust riser, and as the pilot taxis out for departure it gets looser and begins leaking hot exhaust gas in the direction of the CHT 3 probe. And because less hot exhaust gas is passing the EGT 3 probe – or because it’s diluted with fresh air – EGT 3 reads lower, and stays that way through the flight until landing.

Does that explain the GAMI spread? We think so, because the tool is measuring the FF when the EGT peaked, and it’s not aware of the sketchy nature of the EGT number. We’d start by checking the EGT 3 probe for snug.

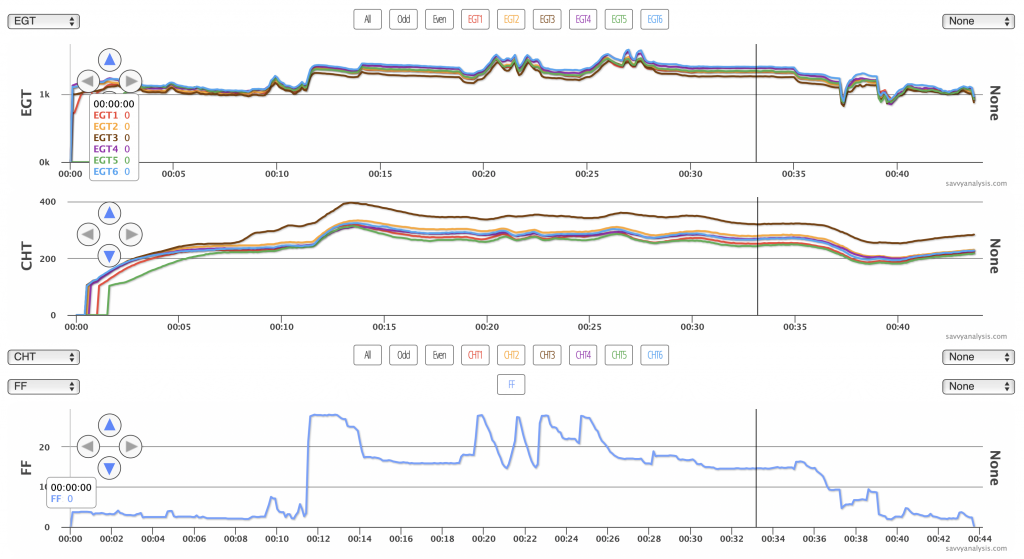

Next up is a Cessna P210 with a Continental TSIO-520 and data from a JPI 930 using a 1 sec sample rate. Here’s the whole flight with EGT, CHT and FF.

The concern is cylinder 3. The GAMI sweeps showed a spread of 2.1 GPH, with 3 running rich. EGT 3 tracks with the other EGTs, but CHT 3 is in its own world, staying even as the others rise and fall, and then taking a big dive as power is reduced for approach.

Let’s also look at this data from a Cessna 182 with a Lycoming IO-540 and data from a Garmin G1000 with a 1 sec sample rate. Here’s the full flight with EGT, CHT and FF.

Here the concern is cylinders 5 and 6. At max FF and when FF is high, both cylinders are cool outliers, then during the mixture sweep at the 34 minute mark EGTs and CHTs rise. The GAMI calculation and a quick visual glance shows 5 and 6 peaking well ahead of the others, but they don’t flame out even when FF bottoms out at 9 GPH. You’d think if the injectors were so clogged that making power was a challenge at max FF then they’d have trouble sustaining combustion at minimum FF. But we don’t see that.

Earlier I planted a seed and let’s tackle that now. A cylinder can run rich because it’s getting too much fuel, or because it’s getting too little air. We can check for too much fuel by swapping injectors or running the bottle test. We can also examine the induction system to be sure it’s delivering the appropriate amount of air to the cylinder.

It’s also possible that a worn cam lobe or a bent pushrod is keeping the intake valve from opening far enough to ingest the right amount of air. A keen eye could probably spot that with a borescope inspection or noting valve movement with the rocker cover off. When the data suggests considering worn cam lobes, we’d expect things to get worse over time as the lobe wears further. With a bent pushrod it might get worse over time, or there might be an accompanying oil leak that offers a clue (which we probably wouldn’t see with a worn cam lobe). If we see signs of a stuck or sticking valve in the data, that’s a tick in the column to look carefully at the pushrods.