It’s that time in the baseball season when teams calculate their magic number – the combination of their wins and losses by others that will clinch the pennant. Computer programmers use the term for something unrelated to baseball. Either way, it seems like a mis-appropriation of the word “magic”. When I think of magic it’s Penn and Teller making a cow disappear – oh, sorry [wink] – an elephant. Something unexpected and unexplained. Something…puzzling.

Savvy Analysis just blew out the candles on our 7th birthday cake, and I’ve been writing these Puzzlers for five of those seven. It occurred to me that we’ve written a lot of reports but never formally explained our thought process for making a recommendation for adjustment – or not. The explanation page that’s attached to each report explains what we’re looking at, but doesn’t mention numbers. So I thought I would use this month’s Puzzler to shed some light on that.

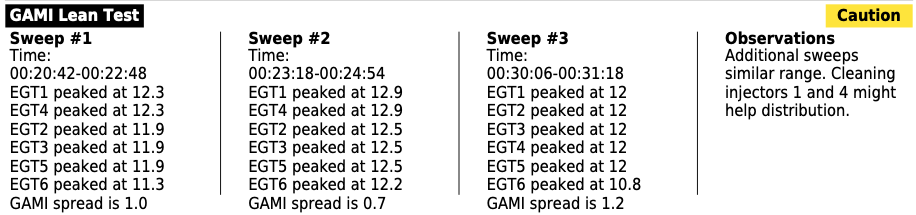

Let’s start with mixture sweeps. For LOP ops in cruise we’re looking for a GAMI spread of 0.5 GPH or less. GAMI says a spread of 0.8 or less should be ok, but our target is 0.5. We often see 0.5 with GAMIs or manufacturer’s position-tuned injectors, and sometimes with luck-of-the-draw factory injectors.

This is from a Cirrus SR22 with a Continental IO-550-N and data from an Avidyne with a 6 sec sample rate.

This spread is higher than it should be for this engine. On this engine and this airframe, 1, 2 and 6 are normally the leanest cylinders. I have a lot of data to back that up and will devote an upcoming Puzzler to it.

We have three options. If these are newly installed GAMIs, GAMI will usually work with the owner to get the spread lower by sending replacement injectors. If these aren’t new and we know from past data that the spread was good once, that would suggest targeted cleaning is in order. Targeted because we only want to clean what needs cleaning. Why not clean them all – just because ? See Mike’s articles or book chapters on MIFs.

This data suggests that cleaning 1 and 4 might help distribution. At least the first two sweeps suggest that – they’re right with the others on sweep three. When we see this we lean toward the preponderance of the evidence. Best two out of three. On these sweeps, 6 is always last to peak and is a rich outlier. So our protocol is to recommend cleaning first, then let’s see if 1 and 4 are back in the pack. Depending on what we see after cleaning, swapping 6 with either 1 or 4 might be worth a try.

Mag check interpretation is probably the toughest topic in learning to be an analyst, because there are so many variables. We’re looking for a rise of about 70-100º F from the top plug to the bottom plug for each cylinder. If we don’t see that, any one of 12 ( or 8 if it’s a four-banger) could be weak, and one or both mags could be mis-timed. At Oshkosh this year electronic ignition was a hot topic, and if one of the mags has been replaced with an e-mag, that’s a whole new set of interpretations.

Here’s a mag check from a Mooney M20K with a Continental TSIO-360 and data from a JPI 830.

EGT 1 had been jumpy before the mag check, and it’s jumpy after the check, so we can’t ignore that. Depending on what we saw in the GAMI sweeps, that low and jumpy reading could be corroboration of an injector clog for cyl 1 – the red trace. If we suspected that, we’d look at takeoff patterns and what happens when leaned for cruise to validate the theory.

If the sweeps didn’t show a clog, the next place to look is at one of the plugs of cyl 1. Usually EGT will rise when one plug shuts down – that’s what the mag check is all about – but It looks like the bottom plugs fire first, then the tops, and it looks like the top plug of the red trace is less jumpy than the bottom.

Usually our wording is to check the plug and harness for the cylinder, because a poor harness can cause weak spark even if the plug is ok. In past Puzzlers we’ve seen harnesses develop cuts and tears in the insulation under an Adel clamp. Tough to see at inspection time unless the clamp is moved, and often the first sign of trouble is something in the data.

It’s hard to conclude from a mag check if the mags are timed properly. We can usually spot if one is ahead of the other, but we can’t say definitively that one is advanced or the other is retarded, or a little of both. Maybe if we compared this mag check to previous mag checks and looked for the delta in the EGTs… Nah, better we should recommend checking mag timing. And we won’t recommend checking just one. Do you know an A&P who would check the timing for one mag but not the other? Hope not.

Now we’re up to the max power settings — FF, RPM and MAP for turbos. We’ll start with FF. For most Continentals, we refer to M-0, which incorporates the settings from the old SID-97. We like to see 0.5 to 1.0 GPH higher than Continental’s, high number. For an SR20 we look for for 17.9 vs Continental’s high number of 17.4. For an SR22 we like the full 1.0 over – so 28.3 vs Continental’s 27.3. We know APS and Barker and others recommend 29 to 30 for that engine. We’ll recommend 28.3 initially, then maybe bump up a little depending on where takeoff CHTs peak. The exception to most is Tornado Alley Turbos, who want to see 35.0 ± 1.0 with MAP at 29.6″.

For Lycomings we report what we see, but we don’t make recommendations for adjustments – we don’t have an M-0 type list to consult, and adjustments on a Lyc are more complicated.

RPMs. Spot on is great, a little low is ok and high is not ok. So for a 2700 redline, we’d call 2680 close enough, and below that probably merits an adjustment. For overspeed, 2710 is acceptable, a brief spike to 2720 would be ok, but a sustained overspeed of 20 or more calls for a visit to the governor. Oscillations and random jumps in RPM are rare, but when we have seen them it’s usually a sign of a loose rod end where the prop cable meets the governor.

MAP. We only report MAP for turbos. For normally aspirated engines it should be whatever ambient pressure is – minus an inch or so for engine plumbing. Again, we look for spot on, a little low is ok and high is not ok. Usually adjusting max MAP will require a FF adjustment, too. Fluctuations in MAP are often related to a sticky waste gate – we recommend a few drops of Mouse Milk every 3 months or so.

For a deeper dive into issues involving MAP, check out this Puzzler from December 2017 by Paul Kortopates.

Five things can cause high CHT readings. Not enough fuel, friction from a broken ring, poor cooling, an exhaust leak torching the probe, and a failed or failing probe sending bad data. The first two are likely to cause other symptoms – the others usually require visual inspection.

EGTs. We’re going to take a new approach to what we offer for EGT analysis when we overhaul the report form. So more about that later.

TIT. Ideally cruise TIT is 50º or so below its redline, Ideally the spread between two TITs is not large.

Sensors. We’re going to take a new approach to this, too, in the new report. We’ll admit it’s a little confusing to use the field called “Inoperative Sensors” to report on which sensors are ok. But we wanted you to know what we looked at in order to be able to report them operative.

We’re usually pretty good at spotting a loose connection vs a failing probe. Often it helps to look at data from previous or subsequent flights to make that determination. I was surprised when I fired up my JPI 830 not long after installation and saw BAD PROBE on CHT 1. I thought “Hey – that’s MY job.” But we’ll take the help – there’s plenty of other stuff it can’t figure out.

Powerplant Management. This is another area that we’ll overhaul with the new report form. When analysis began, we had frequent occurrences of aggressive leaning in the climb leading to high CHTs. That’s less of an issue lately, due to a greater awareness of climb mixture from many directions, including APS and the relentless efforts of Mike Busch.

Voltage. The goal is maximum battery life, so generally for 14 V systems we like to see 13.7 to 14.3, and for 28 V systems 27.7 to 28.3. If there’s something different in your maintenance manual we’ll defer to that. For Cirruses with an MBus and an Ebus, with targets of 28.1 and 28.75 respectively, we look for 27.9 t0 28.3 and 28.5 to 28.9. But if MBus is high and EBus is low we’ll recommend an adjustment to keep that 0.4 V cushion between them.

Hopefully that takes some of the mystery out of the recommendations you get from Savvy analysts. We’re always happy to explain our thought process.