Are you playing Wordle? It’s fascinating to me how this puzzle has caught on as we look for distractions from that other 5-letter word that begins with C and ends with D and has two non-adjacent vowels. What has this got to do with analysis? Well, sometimes – actually, most of the time – we get symptoms and we’re pretty sure what it is, and it turns out we’re correct. Call it 1/6 or sometimes 2/6. We love those green tiles. Other times, it feels more like 4/6 or 5/6 as we sift through the options.

Do you have a favorite starting word? I have one friend that insists that vowels are the key, so starts with words like adieu and canoe. A different friend insists that if you get the consonants right, the vowels fall into place. Hw mprtnt r vwls anhw?

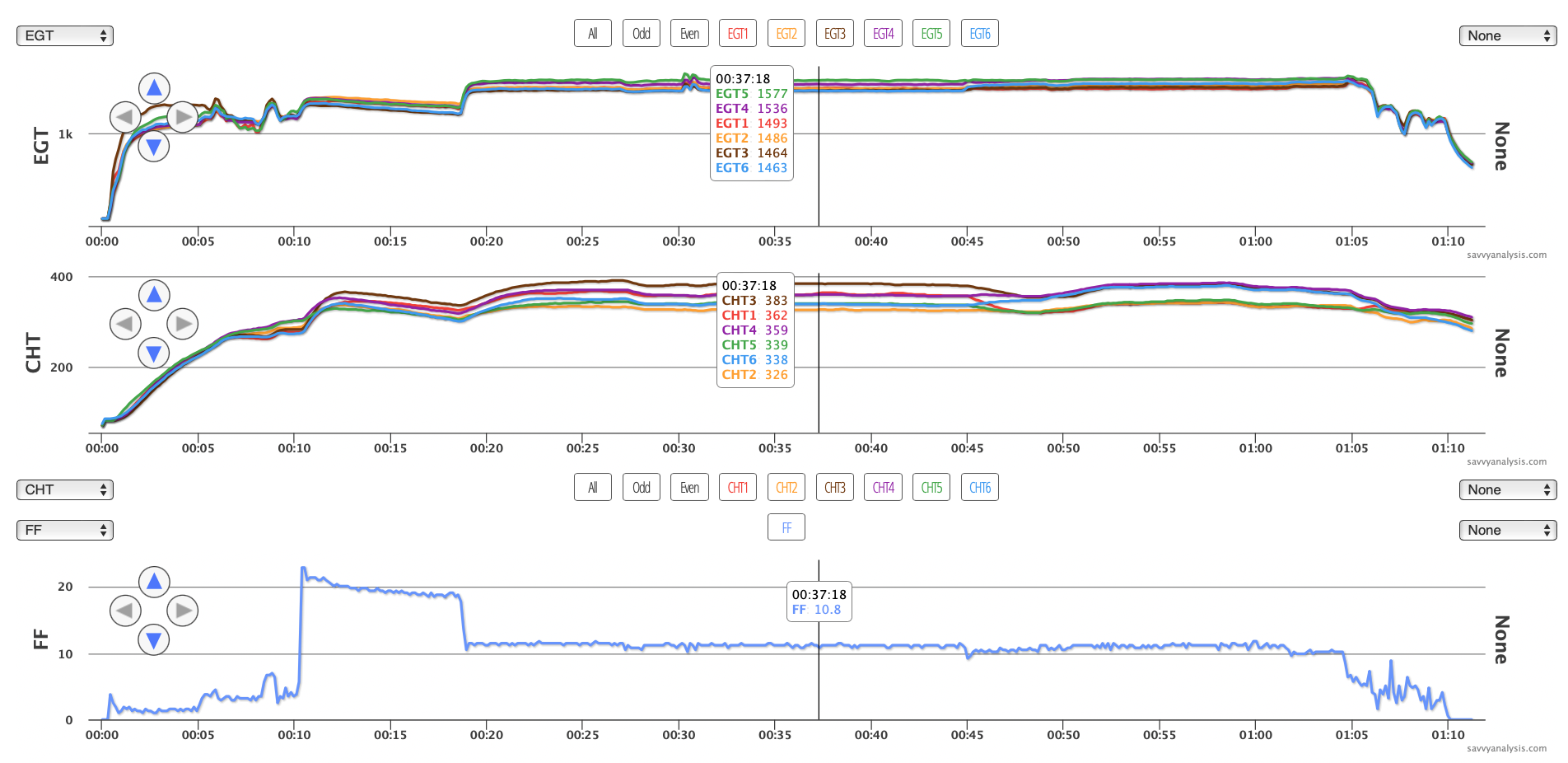

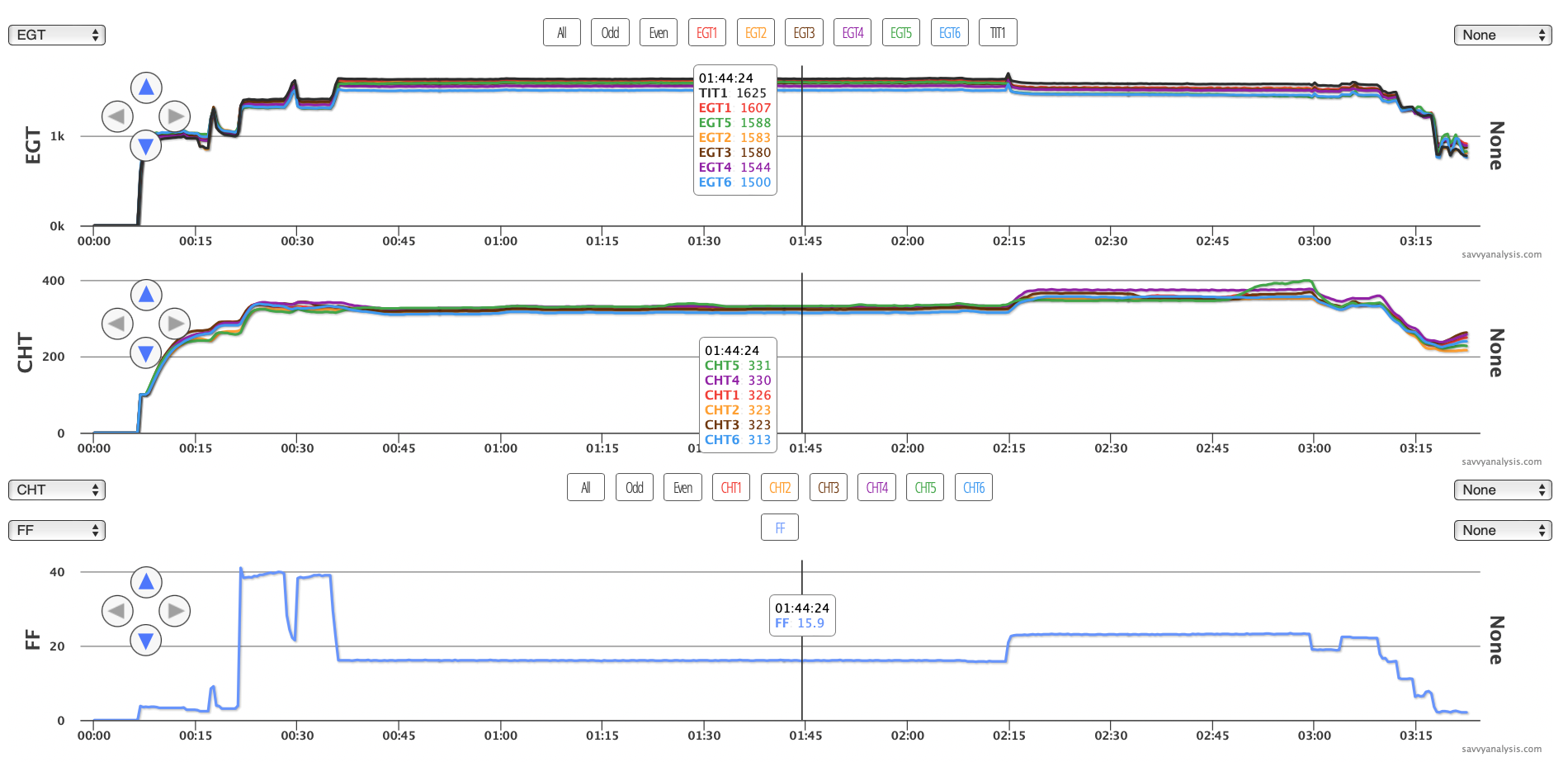

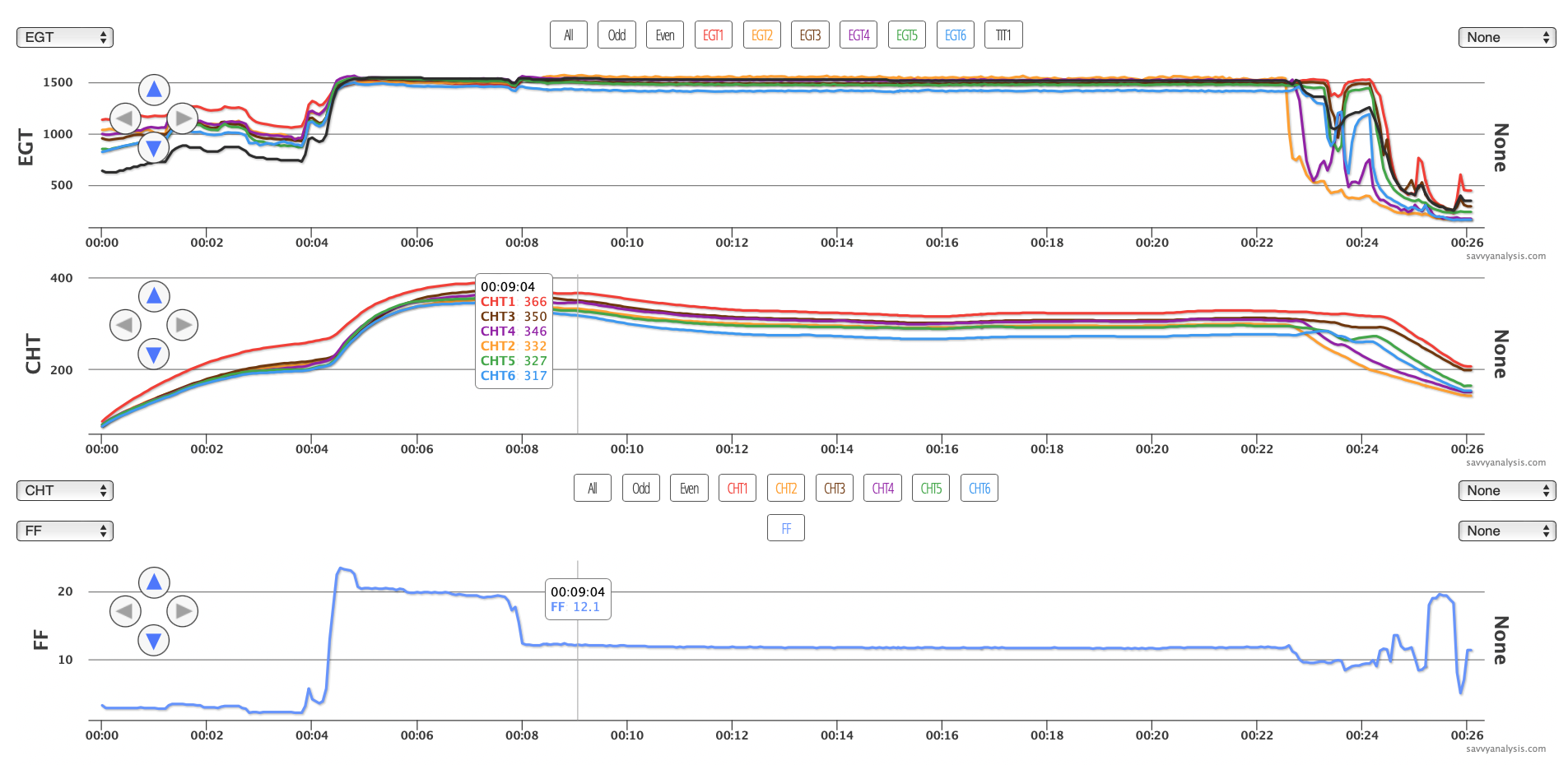

We’ll start this month’s Puzzler with one of the more unusual scenarios we’ve seen. This is from a Cessna 180 with a Continental O-470 and data from an EI CGR-30P with a 1 sec sample rate. Here are EGT, CHT and FF for three flights with about a week between them. Nothing special about cursor placement.

The client reported engine roughness on all recent flights, including these three, and he needed to use a higher FF setting to keep CHT 3 below 400º in cruise. EGT 3 gets a little hotter over the three flights, but CHT 3 was a concern. Injector clogs, fouled plugs and induction leaks all have characteristic patterns – this didn’t look like any of those. Maybe one of the mags was drifting. We asked for a LOP mag check. At that point the client decided his mags were due for overhaul anyway, so this would be a good time to get that done.

When the mags came back, the mag check showed good spark all around, and timing looked good, but there was still roughness. Our thinking shifted to a problem with cylinder 3 itself. A loose cooling baffle could account for higher CHT but not likely to cause roughness. Maybe a broken ring causing extra friction could cause roughness. Just then the client decided to borescope cylinder 3 and discovered a hole in the piston.

That was pretty far down on our list but a good reminder that you can’t take anything for granted.

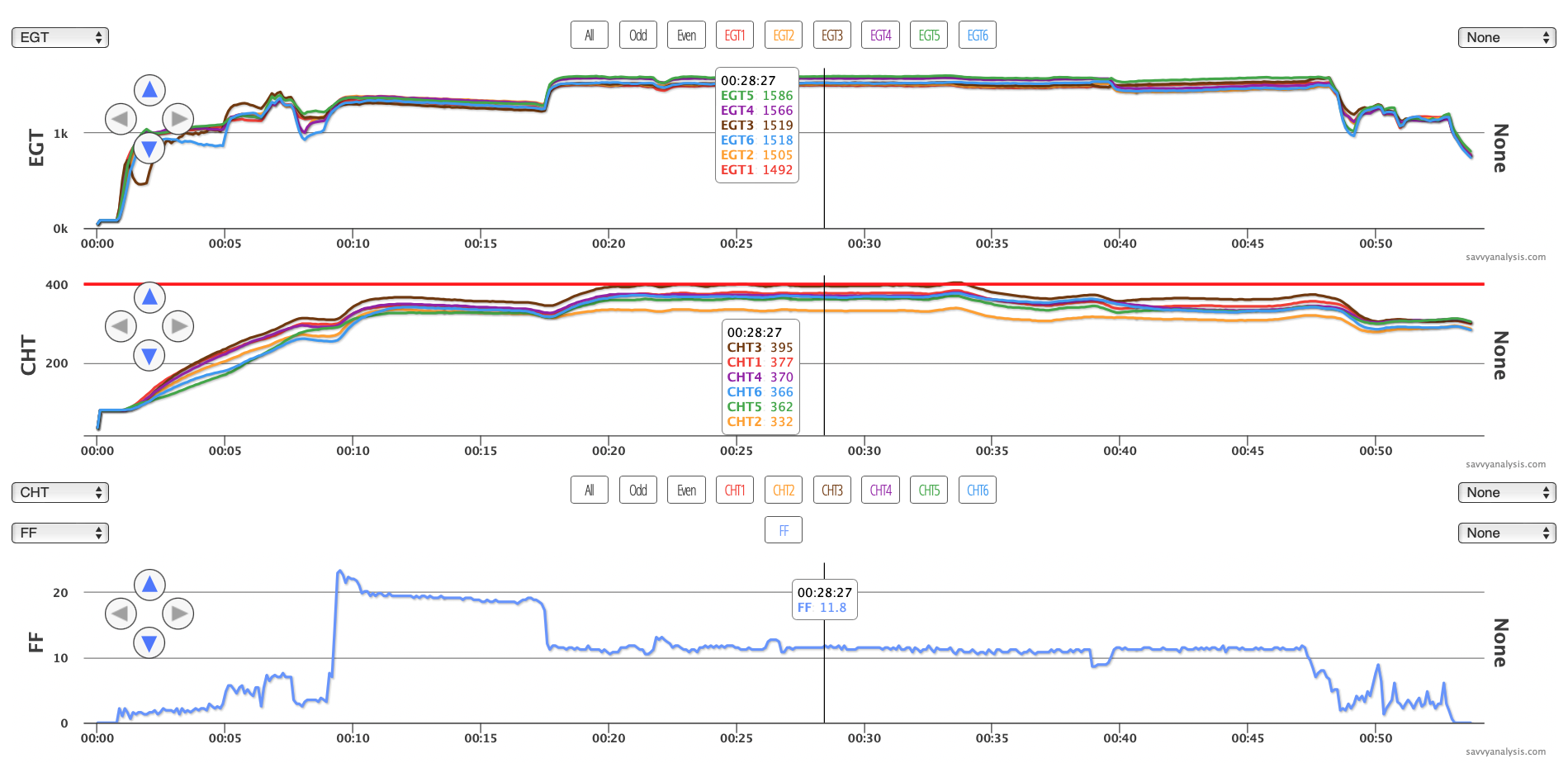

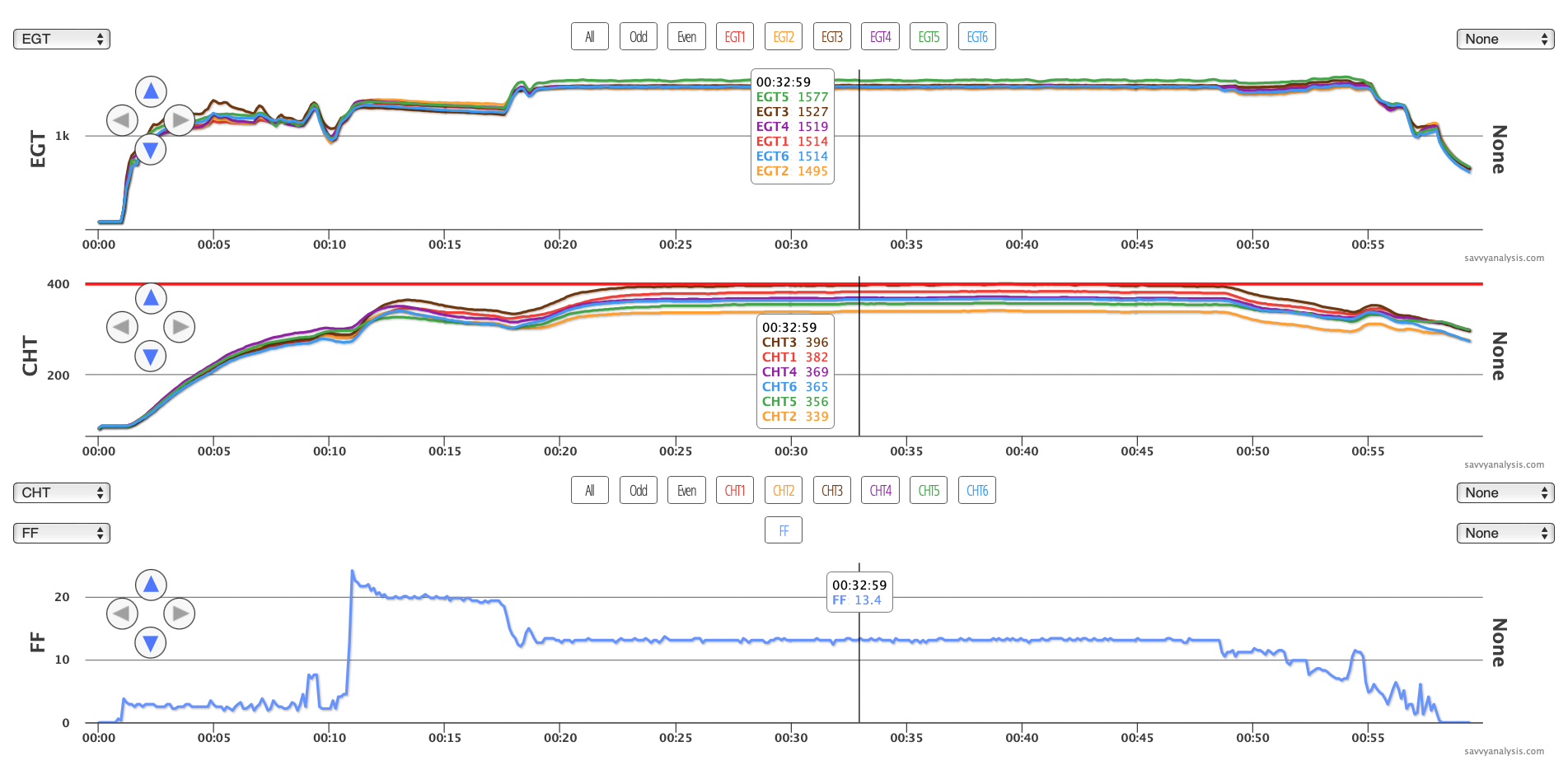

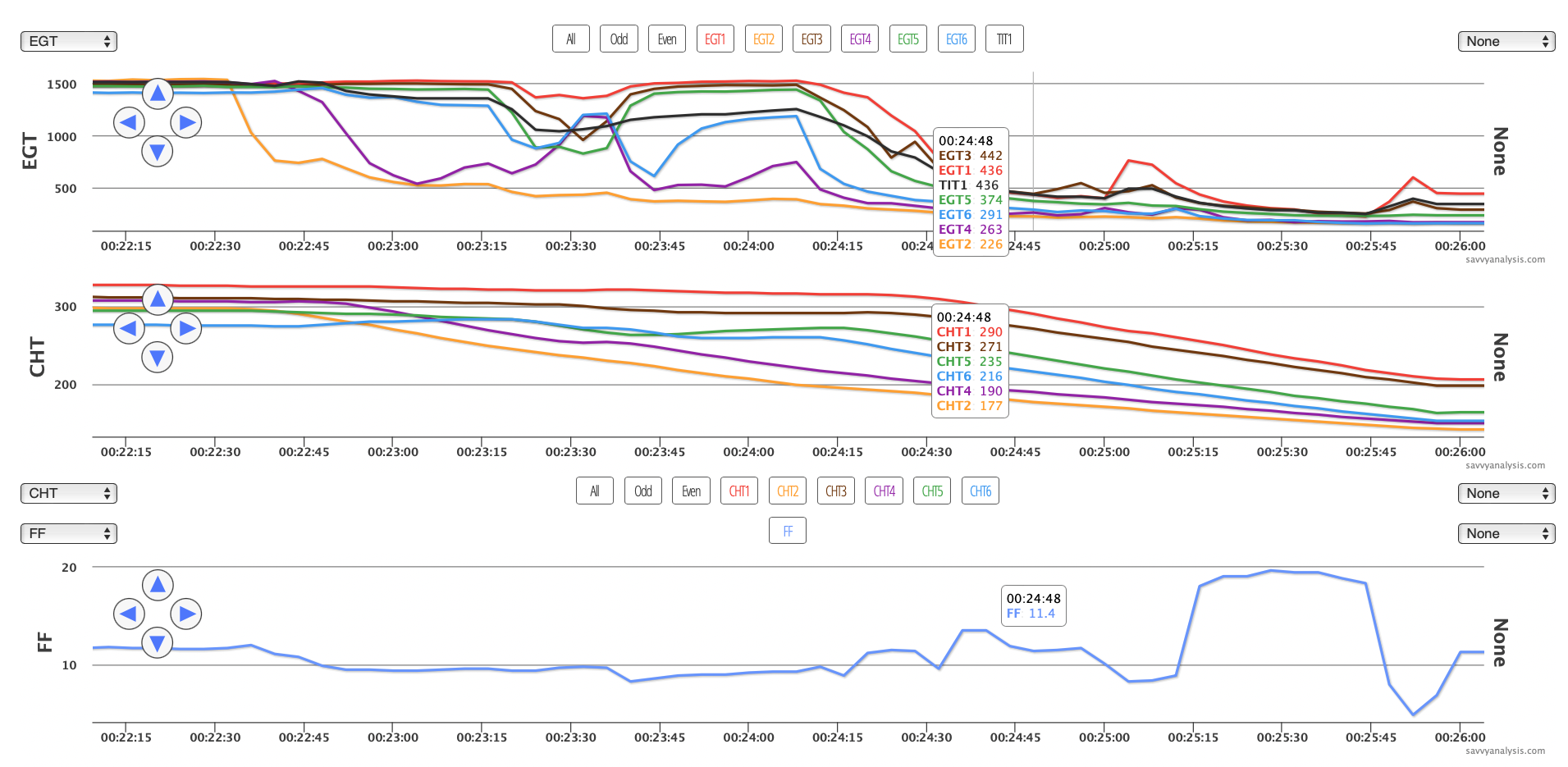

Sticking with the cylinder 3 theme, here are a couple of flights from a Cirrus SR22T with a Continental TSIO-550 engine and data from a Garmin G1000 with a 1 sec sample rate.

Something horrible must be happening with cylinder 3, right? Unless it’s just bad data. No roughness reported, but the client reported that the electric boost pump was not working and causing CHTs to get too high as he approached level-off for cruise. Useful information, or a red herring? The client wanted the boost pump replaced, so the shop did that – but CHTs were still high. The shop changed the boost pump relay – CHTs were still high. Then the shop replaced the new Dukes pump with a new Weldon pump and in the course of checking that install, discovered a significant fuel leak at the mixture shaft on the engine-driven fuel pump. Once they fixed that, CHTs behaved all the way to cruise. But 3 still looked like a mess.

Upon further inspection, it was easy to spot the CHT 3 probe wire loose enough to chafe against the hot exhaust.

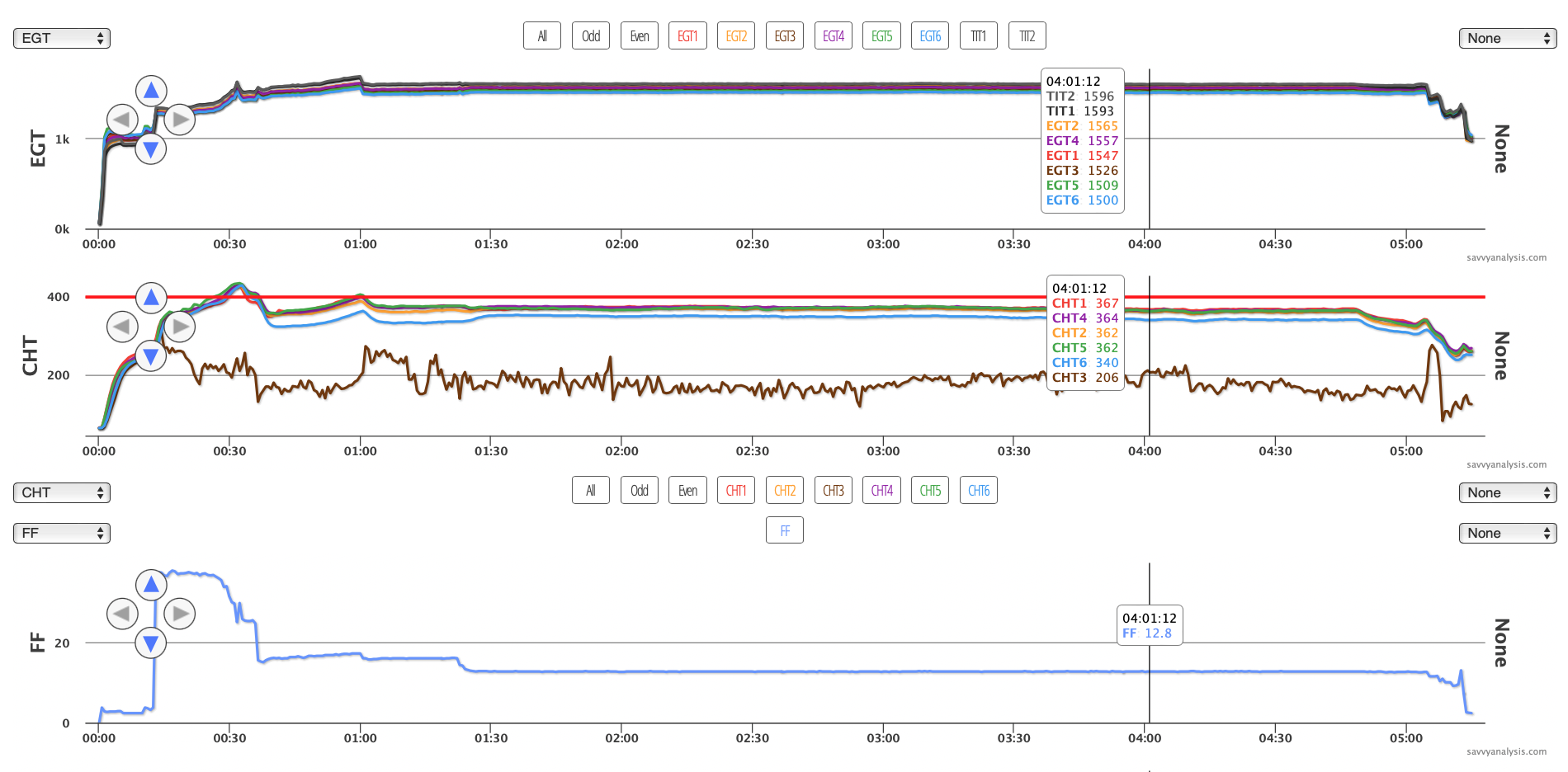

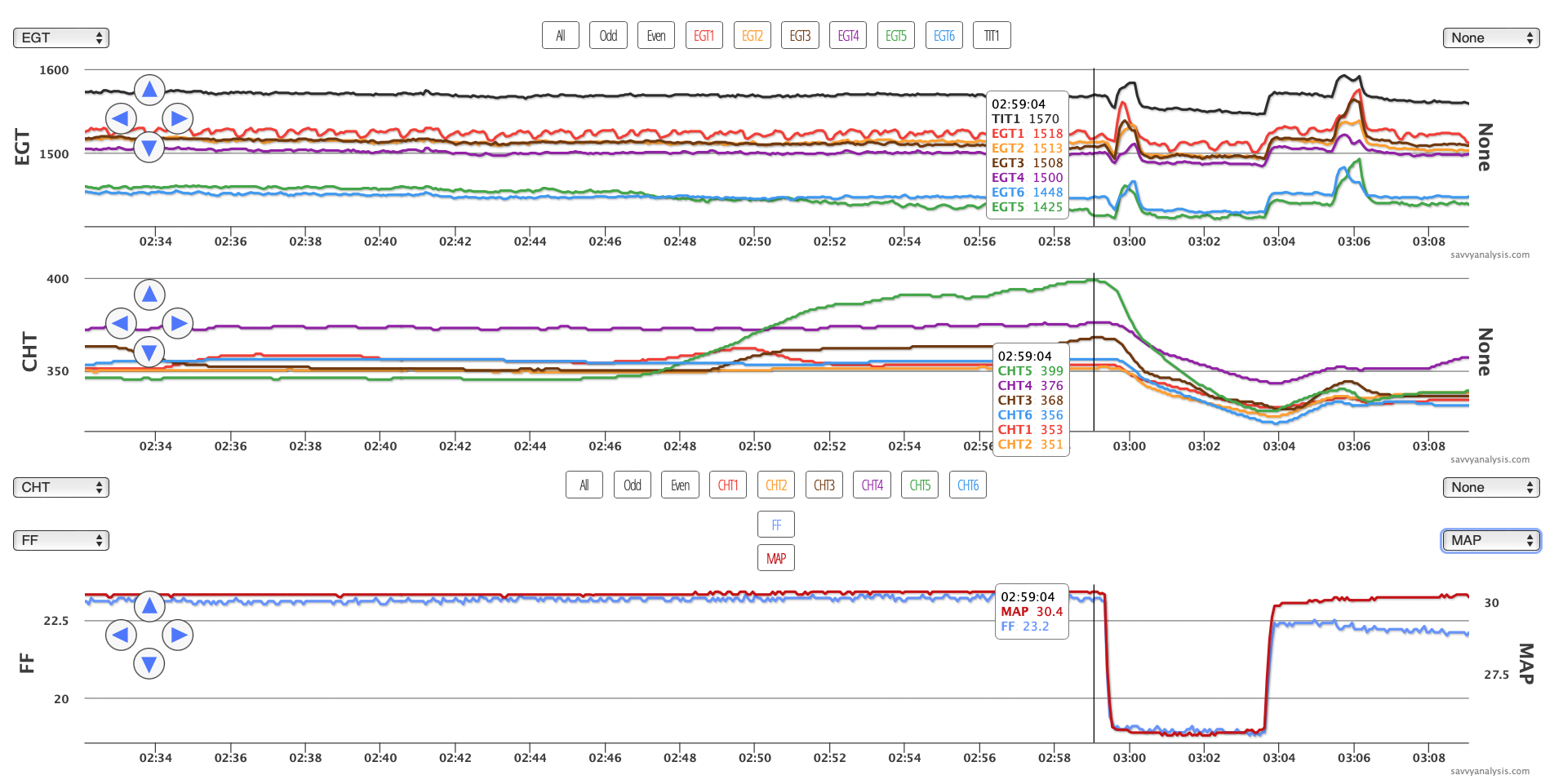

Next is data from a Cessna 400 Corvallis with a Continental TSIO-550 and data from an Avidyne Entegra with a 1 sec sample rate. Here’s the whole flight.

The concern was the rise in CHT 5 at about 02:50 in the timeline. Zooming in, and adding MAP…

Here’s what we noticed —

as 5 has begins its excursion at 02:48, 3 and 1 move a little, but 2-4-6 are pretty steady

CHT 5 climbs about 50º before the pilot “fixes it” by reducing MAP and FF

because a change in power doesn’t initiate the CHT excursion, it’s tempting to point the finger at a cooling problem on that side, but CHT 5 looked normal on subsequent flights

MAP and FF were also normal on subsequent flights, which threw us off the trail. Turns out the turbo failed, and that excursion in CHT 5 was collateral damage.

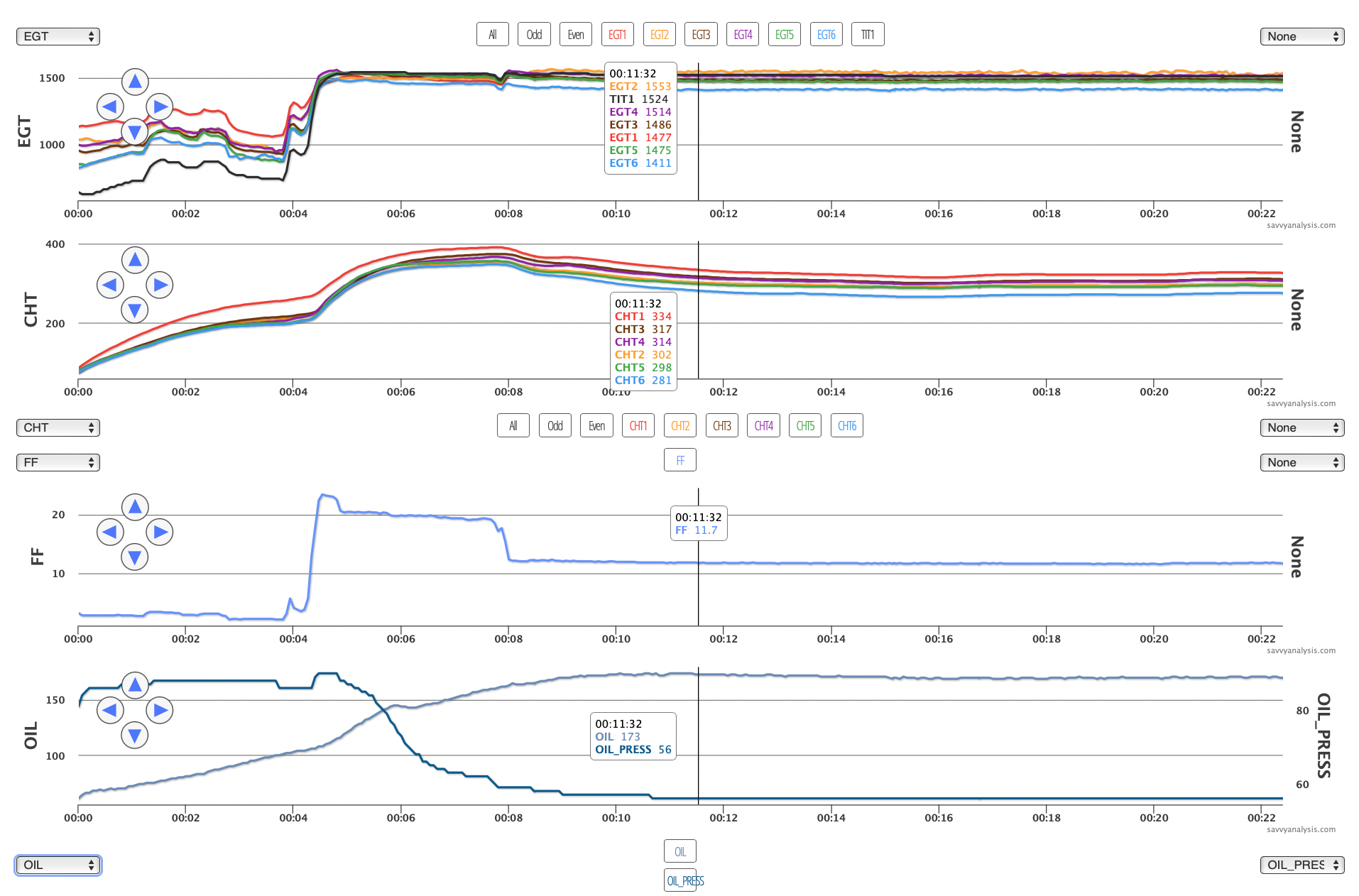

We started this month with a strange one and we’ll end with another. Here’s the beginning of a flight in a Cessna Turbo 210 with a Continental TSIO-520 and data from a JPI 930 with a 4 sec sample rate. This time it’s EGT, CHT, FF, then oil pressure and temp.

Anything catch your eye? Everything’s pretty steady except EGT 2 is high and a bit jumpy. Let’s zoom in on EGTs.

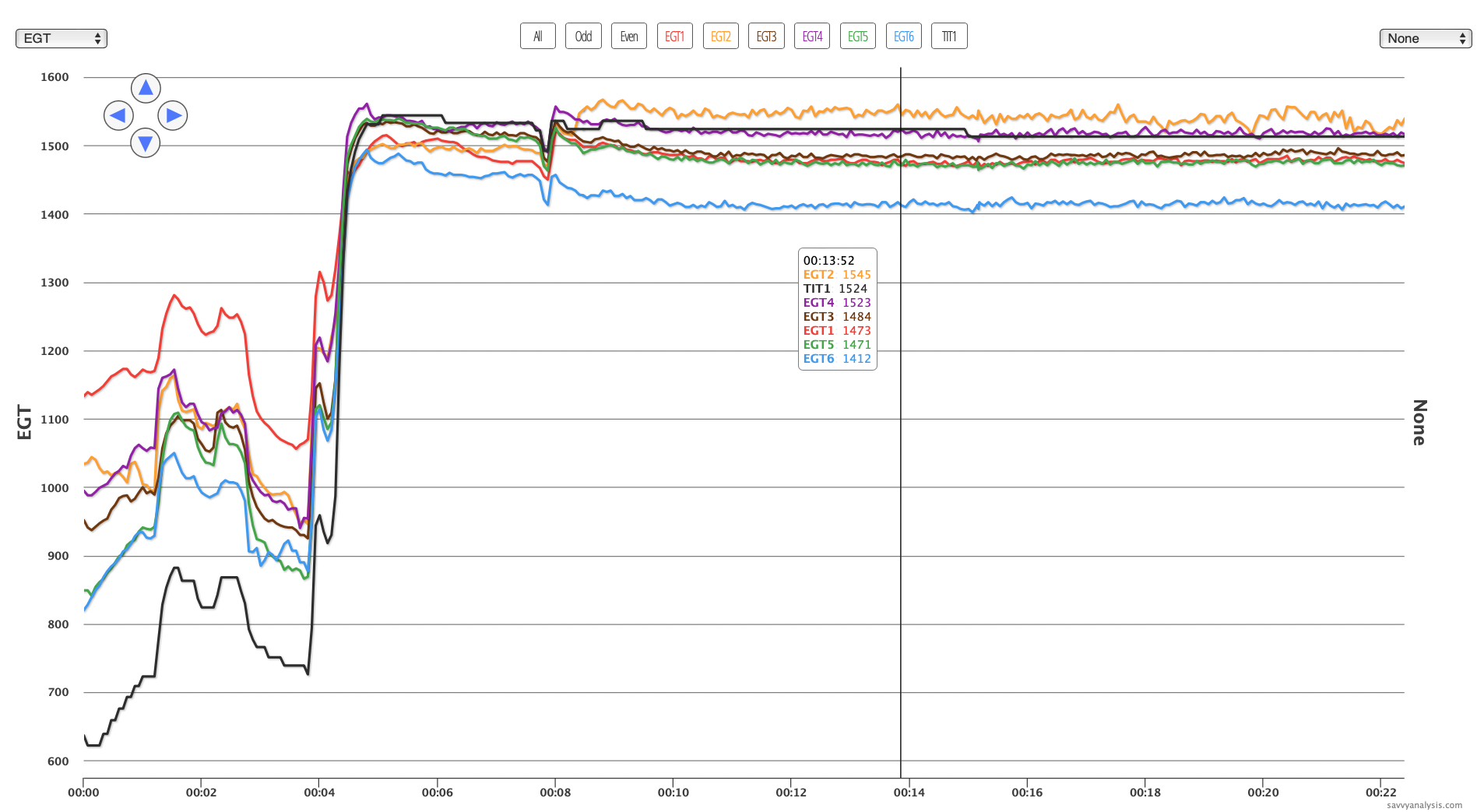

Granted, EGT 2 is jumpy and high, but all EGTs are a little jumpy, and 6 being low seems like more of an anomaly than 2 doing what it’s doing. But 2 is soon going to ruin everybody’s day.

And here’s the same data zoomed into the event.

Client reported —

This flight ended in an off field landing due to engine failure. Initially noted roughness, then #2 and #4 dropped way down. Had brief partial power, then lost all power. On exam cylinder #2 has hole in cylinder cover, borescope shows missing exhaust valve, very damaged piston, with borescope can see crankshaft. Any insight would be welcome. No injuries.

and later —

NTSB says exhaust valve stem just above valve face broke. Piston destroyed into pieces. Intake valve ended up wedged sideways below intake valve port. As you know from the analysis, 2 failed, followed almost immediately by #4. Numbers 1,3,5 failed at the same time about 1 minute 45 seconds later. Mechanic and FAA initially assumed this was the engine seizing, but I told them, backed up by the download, that the prop kept windmilling until touchdown.

Was the high and jumpy EGT a clue? This wasn’t a burned spot on the valve – the kind we try and spot with FEVA. In this case the whole valve face separated from the valve stem.